Automatic assembling equipment for eccentric cam and check ring of three-convex balance wheel seat and assembling process of automatic assembling equipment

An eccentric cam and automatic assembly technology, applied in metal processing equipment, assembly machines, metal processing, etc., can solve problems such as low efficiency and inability to meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

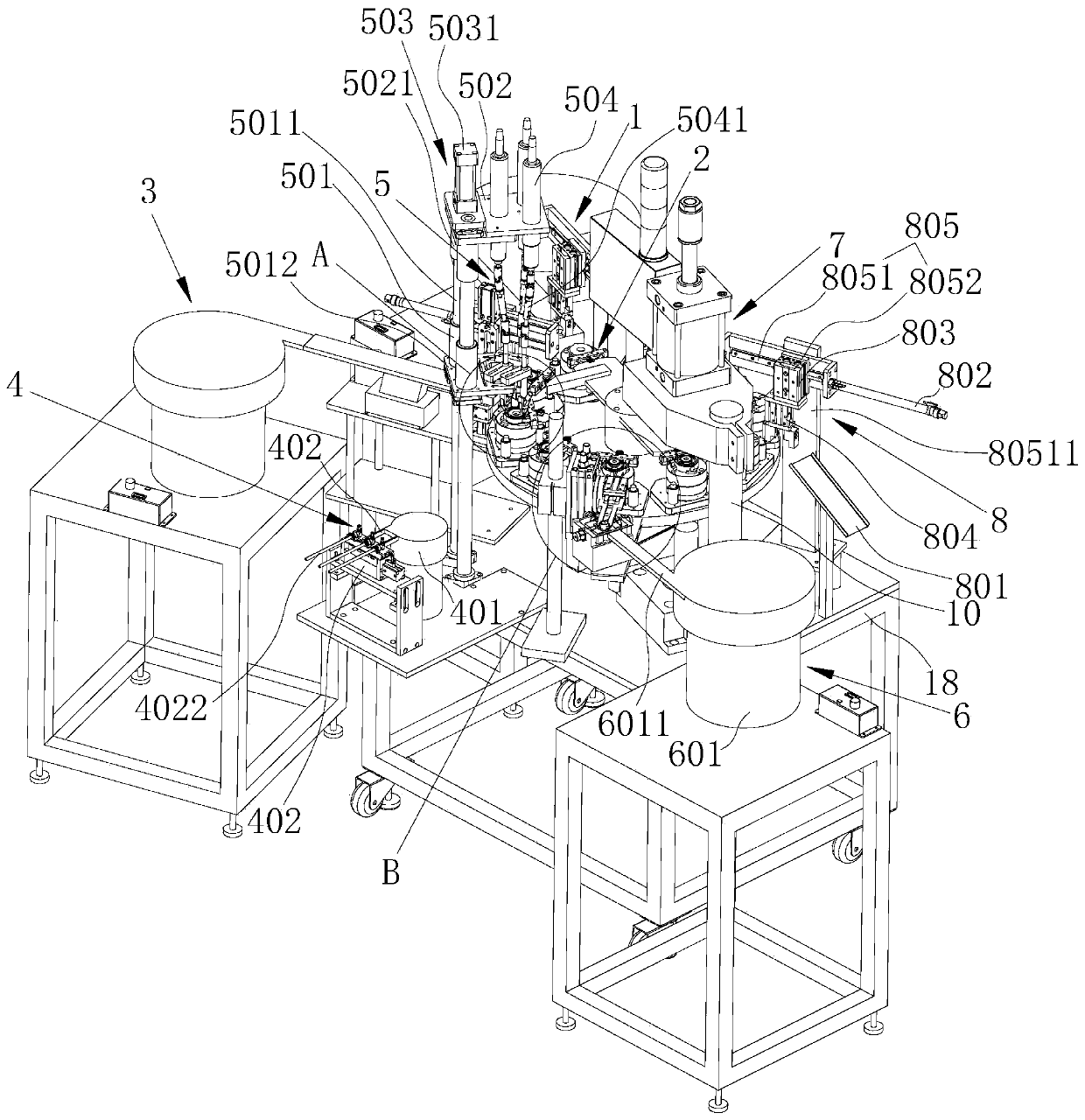

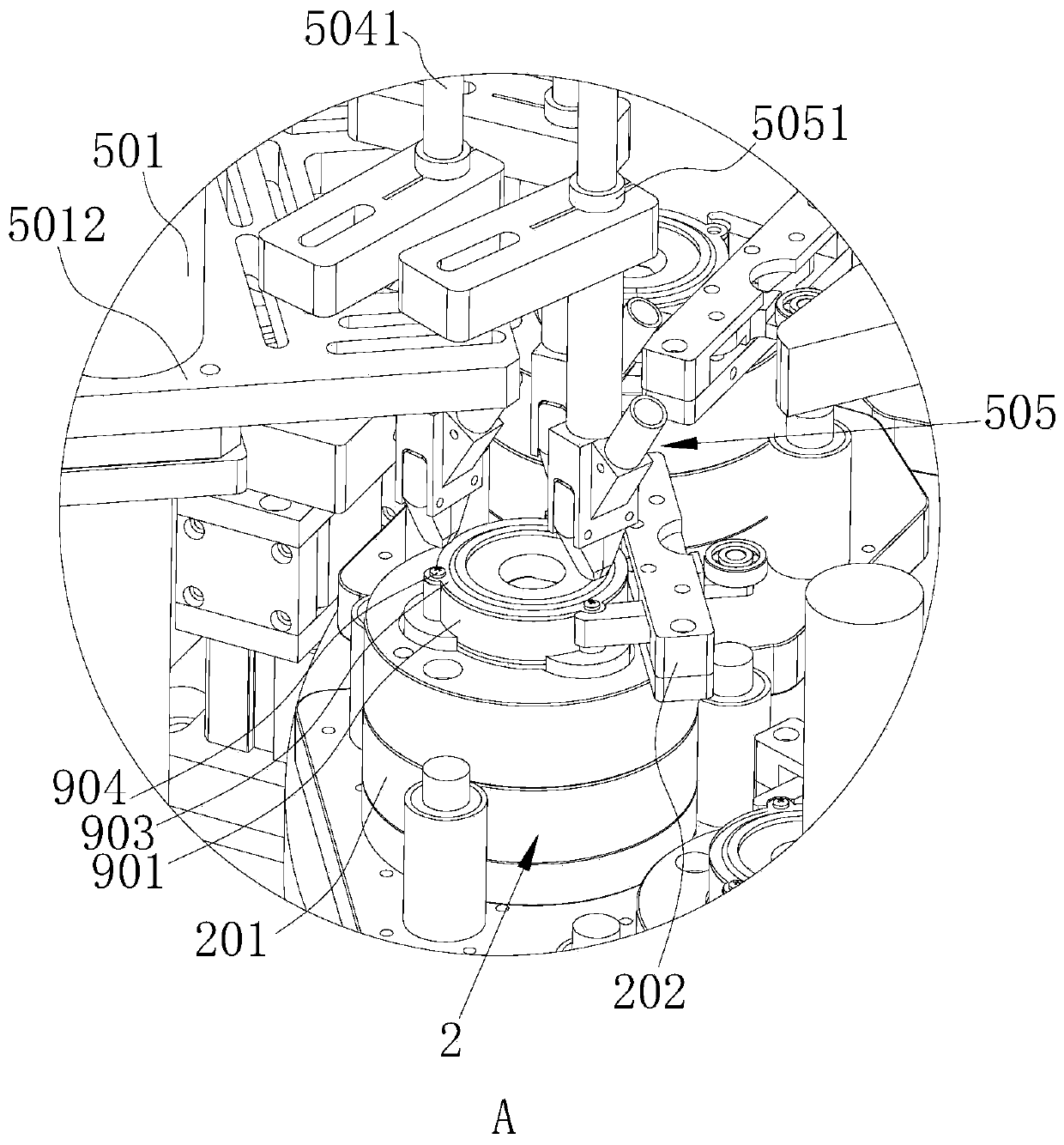

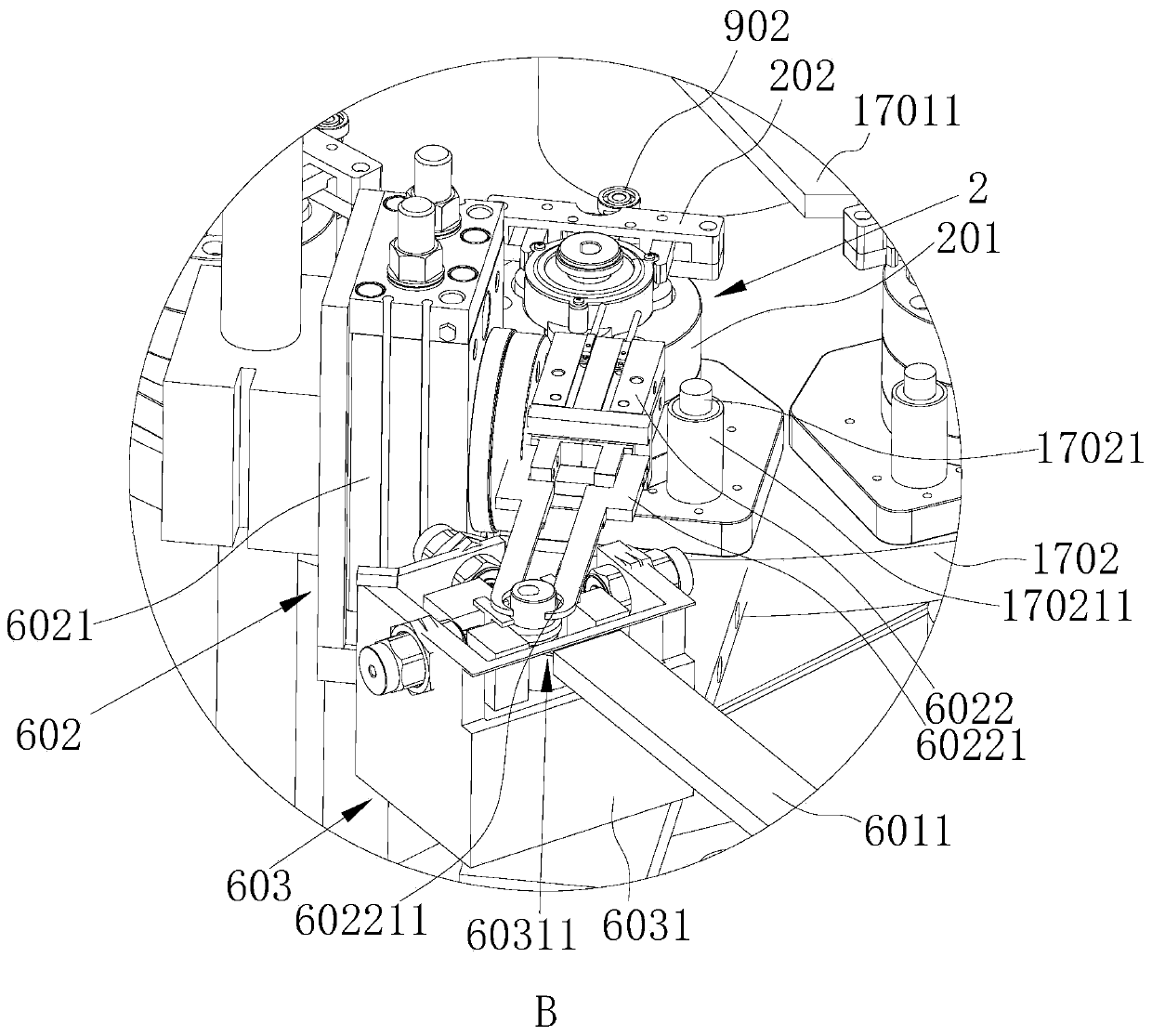

[0096] refer to figure 1 , figure 2 as well as image 3 , this embodiment discloses an automatic assembly device for an eccentric cam and a retaining ring of a three-convex balance wheel seat, including a balance wheel seat feeding device 1, a balance wheel seat positioning and clamping device 2, a retaining ring feeding device 3, and a screw feeding device 4. Screw screwing device 5, eccentric cam loading device 6, eccentric cam pressing device 7 and unloading device 8, balance wheel seat loading device 1 loads balance wheel seat 901 to balance wheel seat positioning and clamping device 2 , the balance wheel seat positioning and clamping device 2 is used for positioning and clamping the balance wheel seat 901, the retaining ring feeding device 3 and the screw feeding device 4 respectively feed the retaining ring 903 and the fastening screw 904 to the balance wheel seat On the positioned and clamped balance wheel seat 901 on the positioning and clamping device 2, the eccen...

Embodiment 2

[0174] This embodiment discloses an automatic assembly process for an eccentric cam and a retaining ring of a three-lobed balance wheel seat. Based on the automatic assembly equipment for an eccentric cam and a retaining ring for a three-convex balance wheel seat in the above embodiment, the automatic assembly process includes the following steps:

[0175] S1: The balance wheel seat loading device loads materials, and transports the balance wheel seat to the balance wheel seat positioning and clamping device, and the balance wheel seat positioning and clamping device positions and clamps the balance wheel seat;

[0176] S2: The retaining ring feeding device feeds the retaining ring to the balance wheel seat positioning and clamping device, and the balance wheel seat positioning and clamping device positions and clamps the retaining ring;

[0177] S3: The screw feeding device feeds the material, and quantitatively transports the fastening screws to the screw screw device;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com