Autoclaved aerated concrete plate with pre-buried pipes and preparation method of autoclaved aerated concrete plate

A technology of autoclaved air filling and concrete slabs, which is applied in the direction of manufacturing tools, building components, ceramic molding machines, etc., can solve the problems of low prefabrication, dust pollution, and long construction period, and achieve high prefabrication and dust pollution. The effect of small size and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

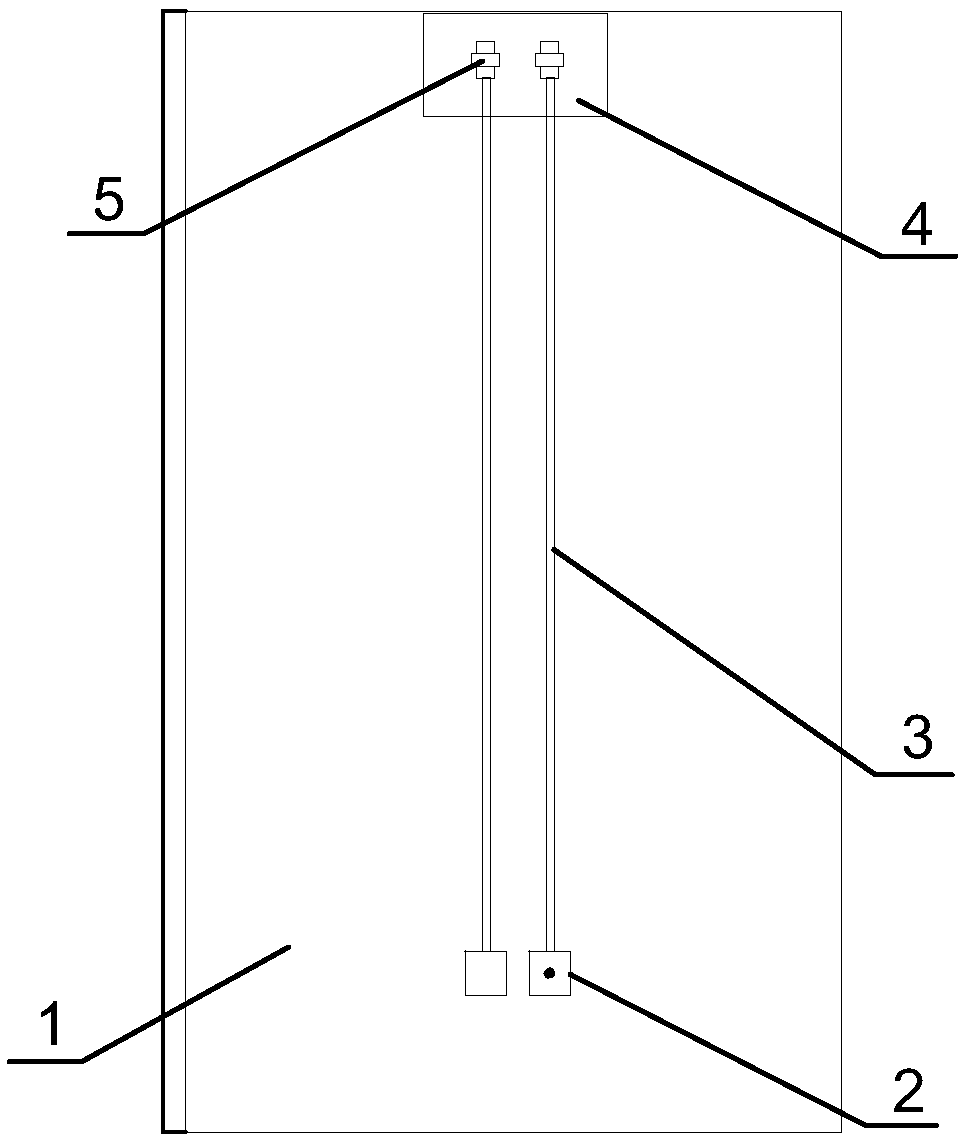

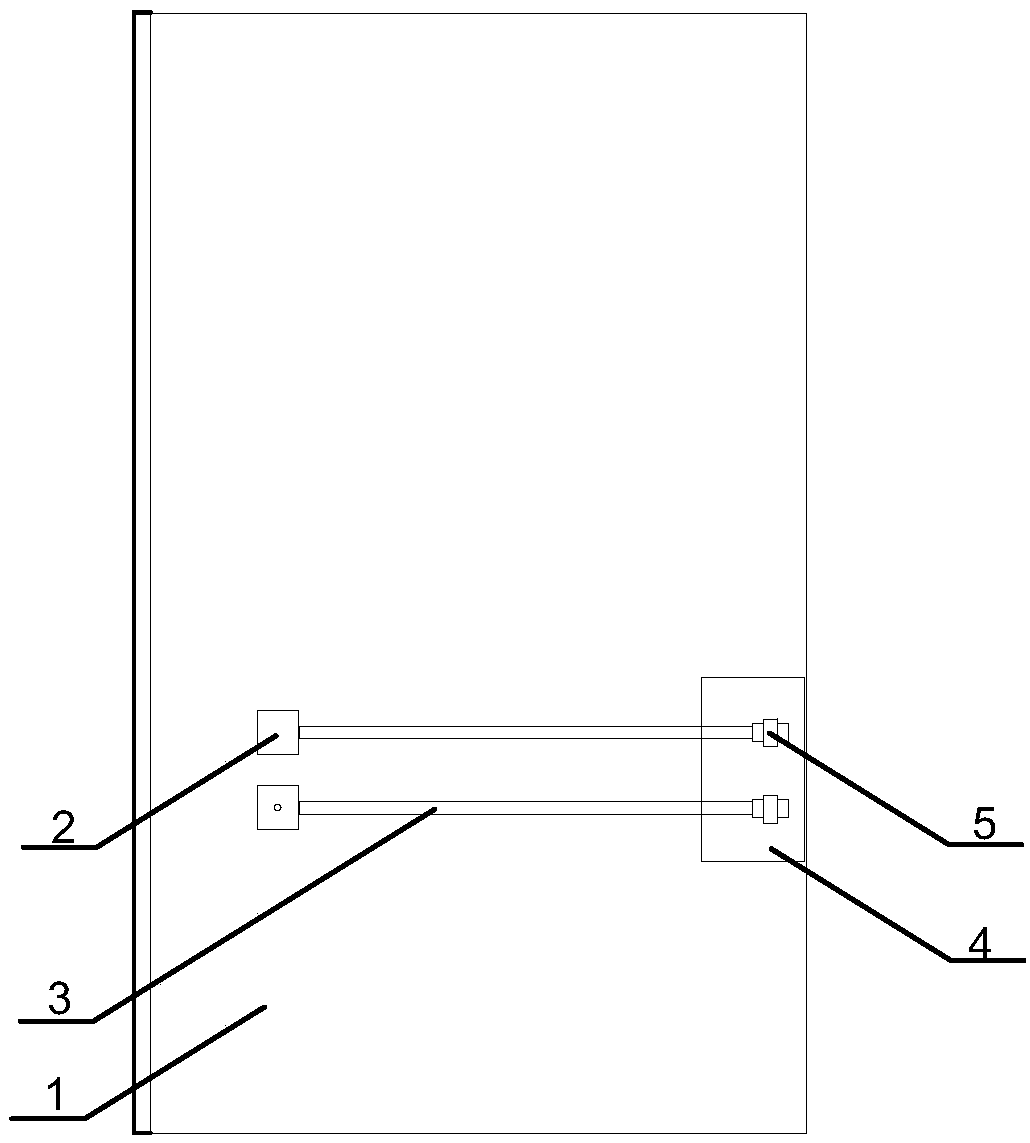

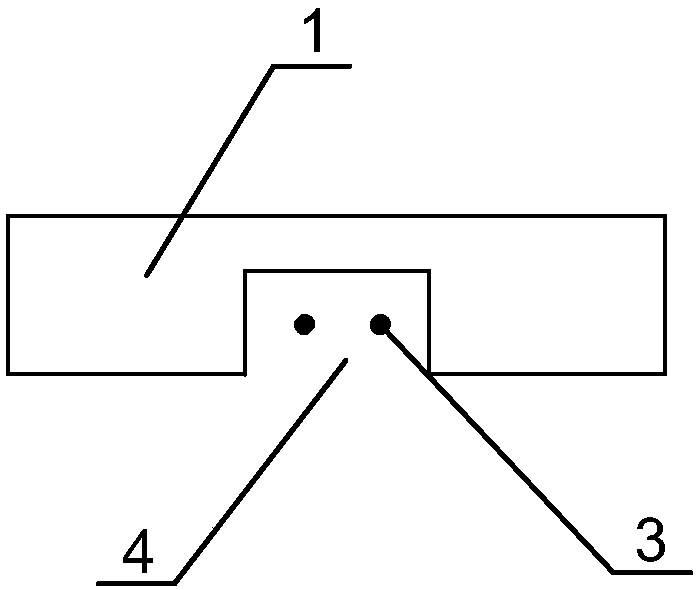

[0022] As shown in the figure: the autoclaved aerated concrete slab with pre-embedded pipes in this embodiment includes the autoclaved aerated concrete slab body 1 and the pre-embedded pipe 3 and inserting pipe 3 arranged inside the autoclaved aerated concrete slab body 1. Junction box 2, the plug-in box 2 is arranged at one end of the embedded pipe, and the embedded pipe can be as figure 1 As shown along the longitudinal direction of the autoclaved aerated concrete slab body 1, it can also be as figure 2 It is shown along the transverse direction of the autoclaved aerated concrete slab body 1, of course, it can also be set as an oblique direction (not shown in the figure).

[0023] In this embodiment, the autoclaved aerated concrete slab body 1 is provided with a groove 4 at one end of the embedded pipe without a plug-in box, and the end of the embedded pipe 3 without a plug-in box is provided with a quick-fit joint 5 . Fast docking of the wall can be realized when assembli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com