Connection Point For Metal Structure

a connection point and metal structure technology, applied in the field of connecting points of metal structures, can solve the problems of lack of flexibility in the assembly, inability to be separated to be adequately rearranged or positioned, and the type of connection stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0004]The invention proposes to resolve this question, for which on the one hand it is possible to execute a fast and effective pre-assembly of the structure and, once it has the adequate configuration and all its elements are in the definitive position, the nodes are definitively fixed. This fixation is preferably performed by means of screws, although it may also be the object of riveted joints.

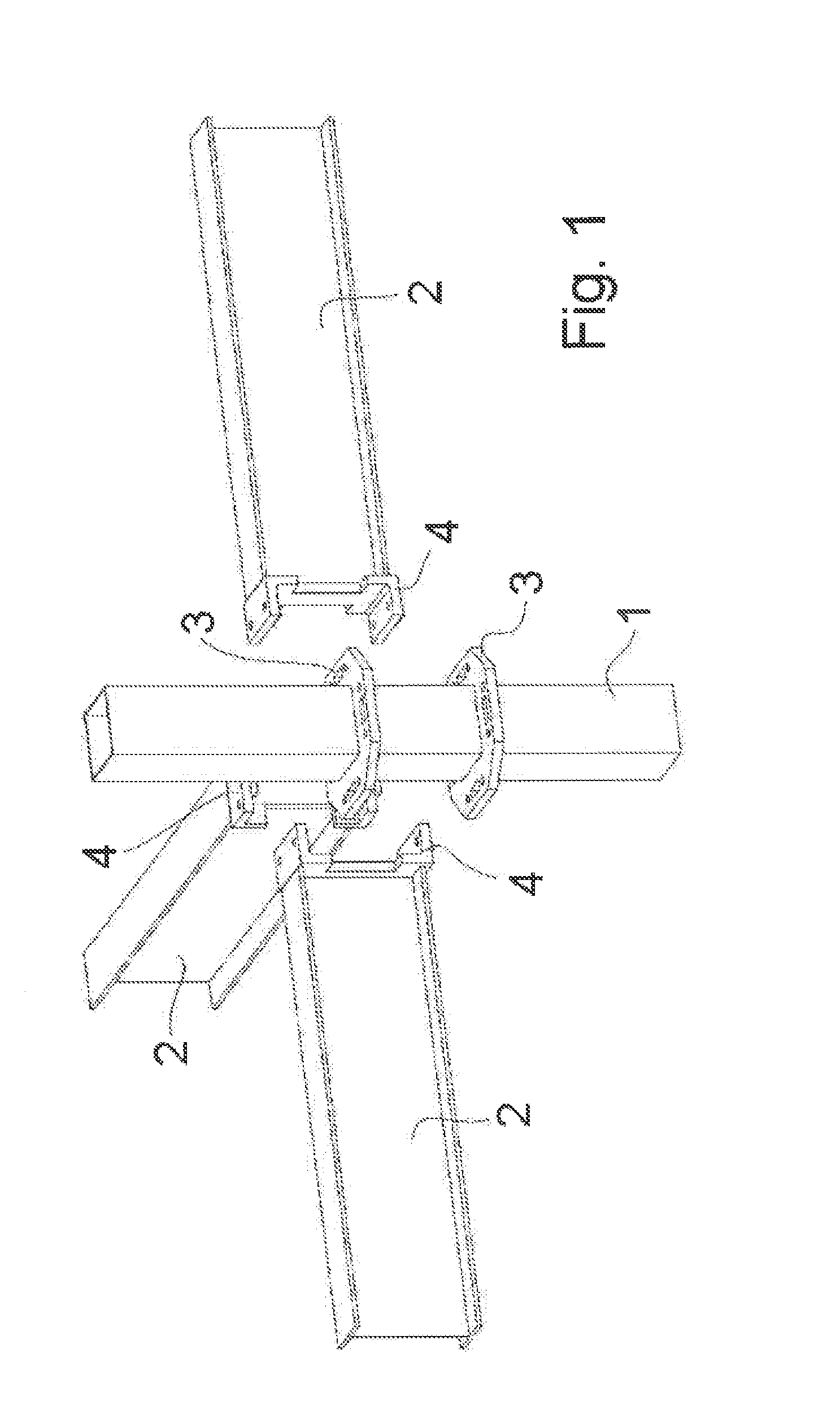

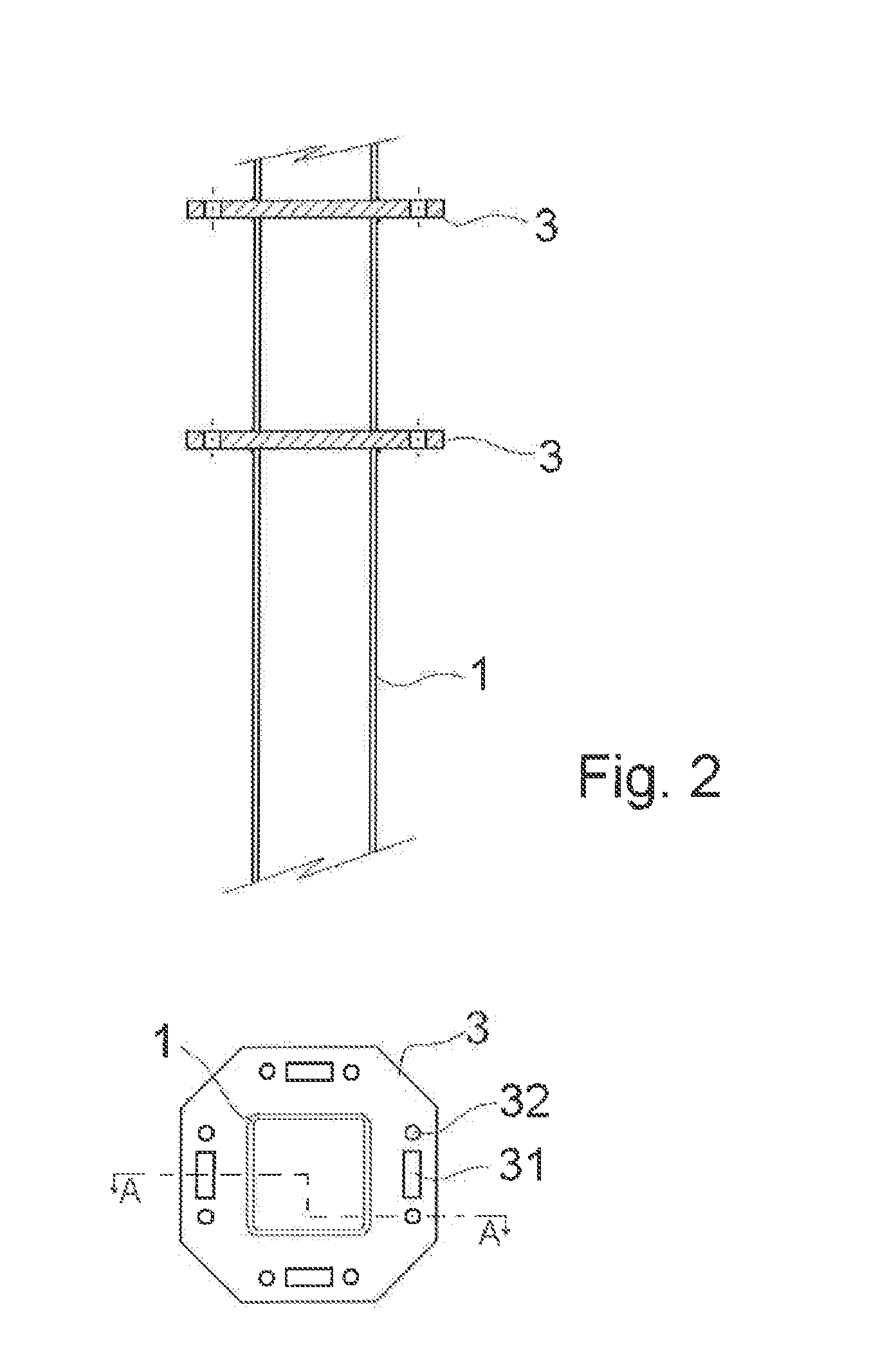

[0005]The pre-assembly of the constituent parts of a node can only be executed in a stable position, wherein the parts adopt well-defined and geometric positions which therefore do not require subsequent adjustments. For example, on assembling several beams on a prop disposed at 90°, the interlocking thereof is necessarily a right angle, i.e. perpendicular to the sides of the prop and it is only possible with a minimum tolerance margin.

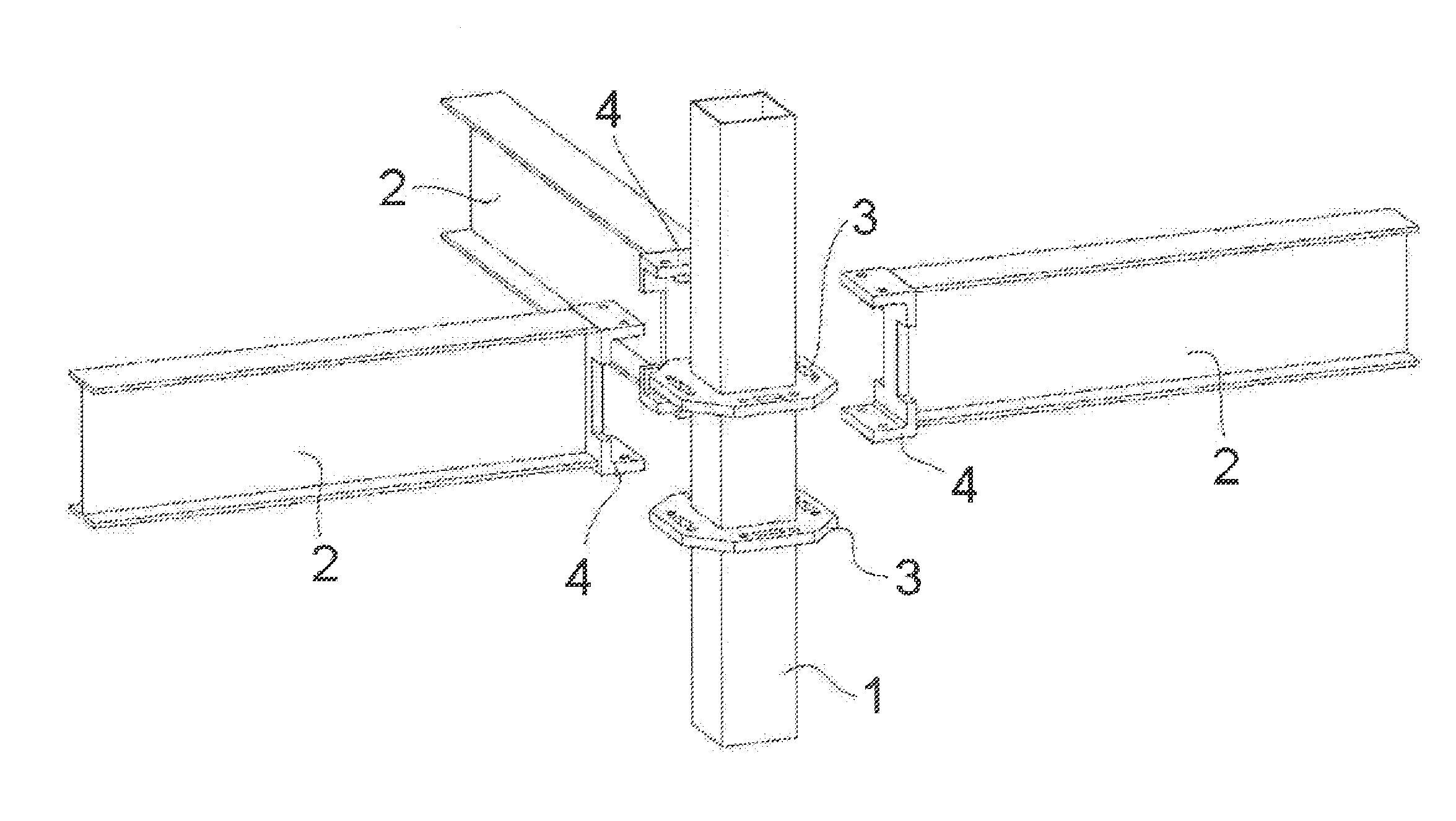

[0006]This node is composed of two differentiated elements: a post or pillar having coupling means for the relevant beams at an adequate height or heights, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com