Dry-connected prefabricated assembled steel-concrete composite beam

A technology of prefabricated assembly and composite beams, which is applied in the direction of structural elements, building components, and long-strip structural components for load-bearing, etc., can solve the problems of long construction period and difficult to reuse, so as to speed up the construction progress, reduce costs, Achieve the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The so-called dry connection in the present invention refers to the connection form between the concrete member and the steel member or the connection between the concrete member and the concrete member by mechanical means (such as welding, bolt connection, tenon connection) as an integral structure. The cast-in-place concrete realizes the connection corresponding to the concept of "wet connection".

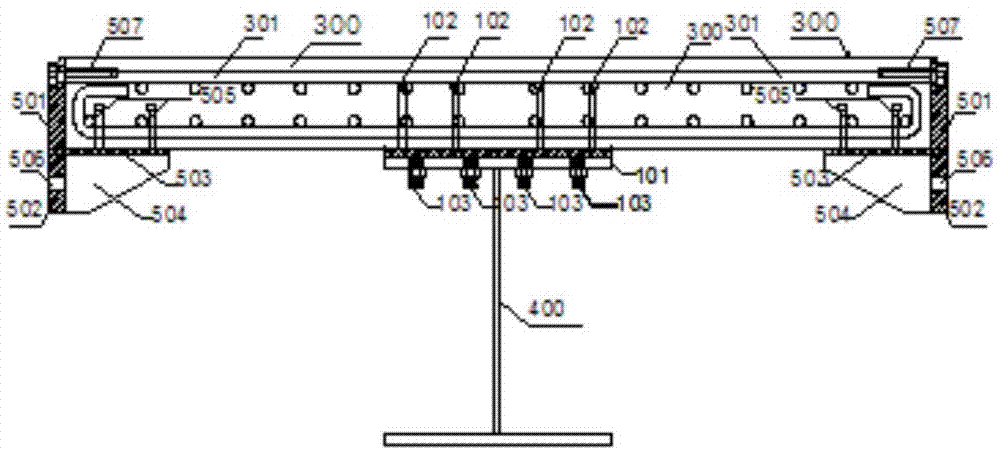

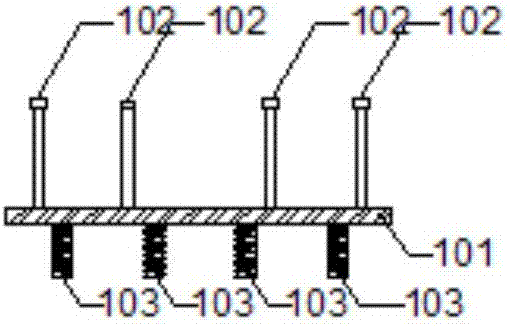

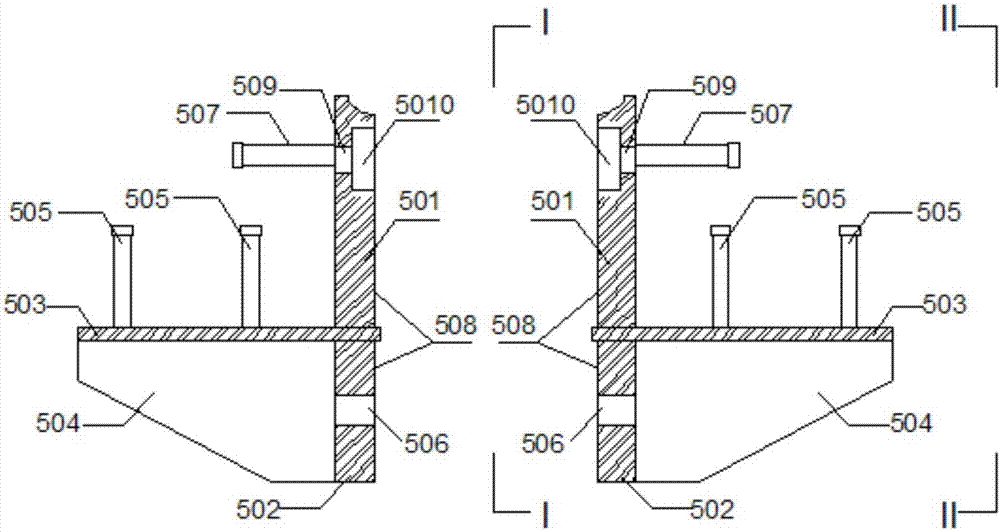

[0020] Such as Figure 1-5 Shown, a kind of dry-type connection prefabricated assembled steel-concrete composite beam comprises a steel beam, a concrete slab made of steel bars and concrete, a steel plate connector made of steel plates, shear connectors and connecting rods, and a steel plate connector 100 ( See figure 2 ) The steel plate 101 in ) is arranged horizontally, the steel shear connector 102 is vertically welded on the upper surface, and the connecting rod 103 is vertically welded on the lower surface. It also includes a pair of inter-plate connectors consisti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com