Prefabricated concrete beam column connecting node structure and construction method thereof

A prefabricated concrete, beam-column connection technology, applied in building construction, construction, building material processing and other directions, can solve the problems of difficult formwork support, inconvenient construction, and cumbersome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

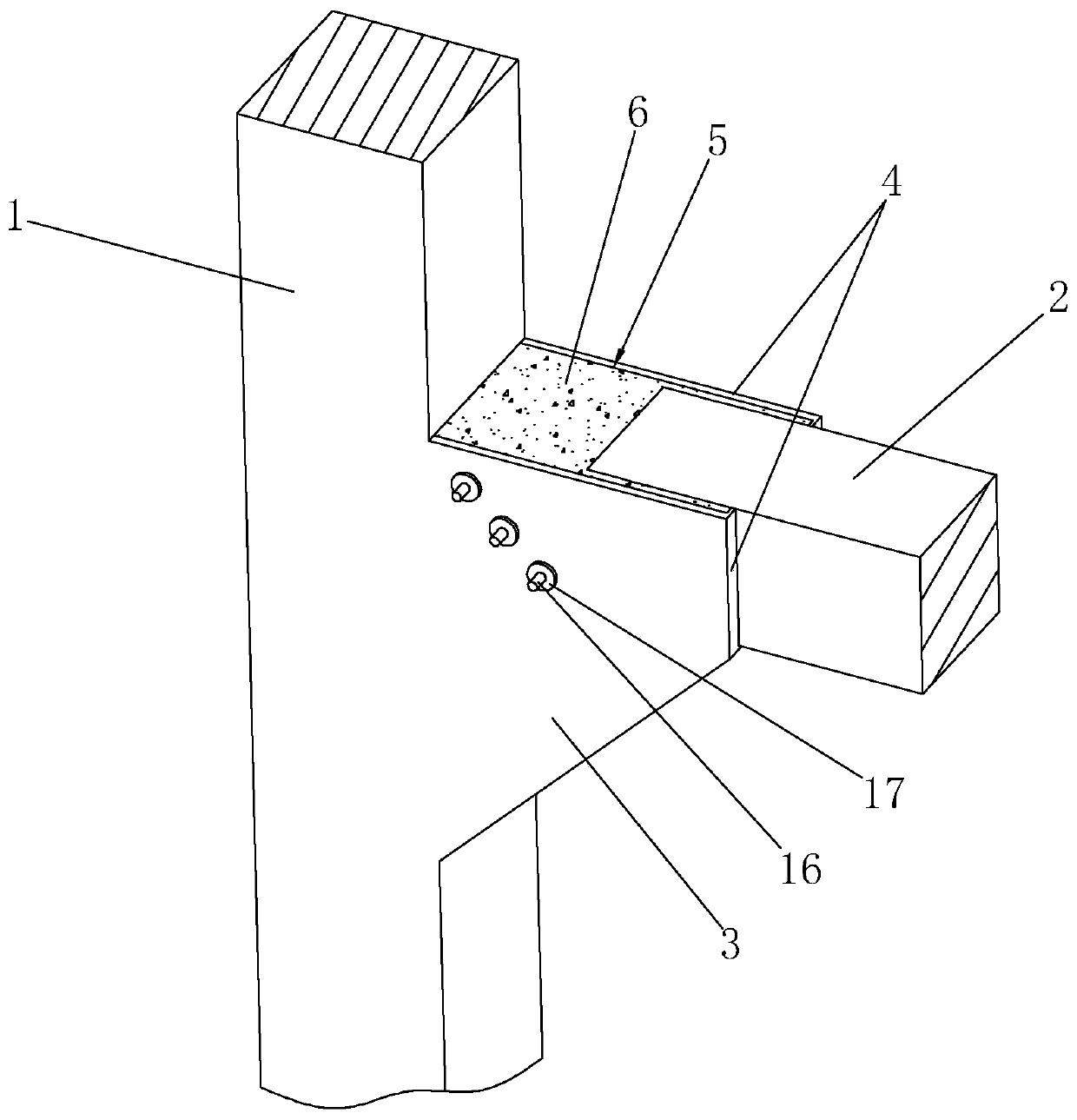

[0039] Such as figure 1 As shown, a precast concrete beam-column connection node structure includes a precast concrete beam 2 and a precast concrete column 1, a cap 3 is provided on the precast concrete beam 2, and wing plates 4 are provided on both sides of the cap 3 in the width direction. The plate 4 is connected to the platform 3 and the precast concrete column 1 . The wing plate 4, the platform cap 3 and the prefabricated concrete column 1 are integrally poured and formed. An installation groove 5 for pre-connection of the precast concrete beam 2 is formed between the wing plate 4 and the platform 3, and the area enclosed by the precast concrete column 1, the precast concrete beam 2, the platform 3 and the wing plate 4 is poured with concrete A cast-in-place portion 6 is formed.

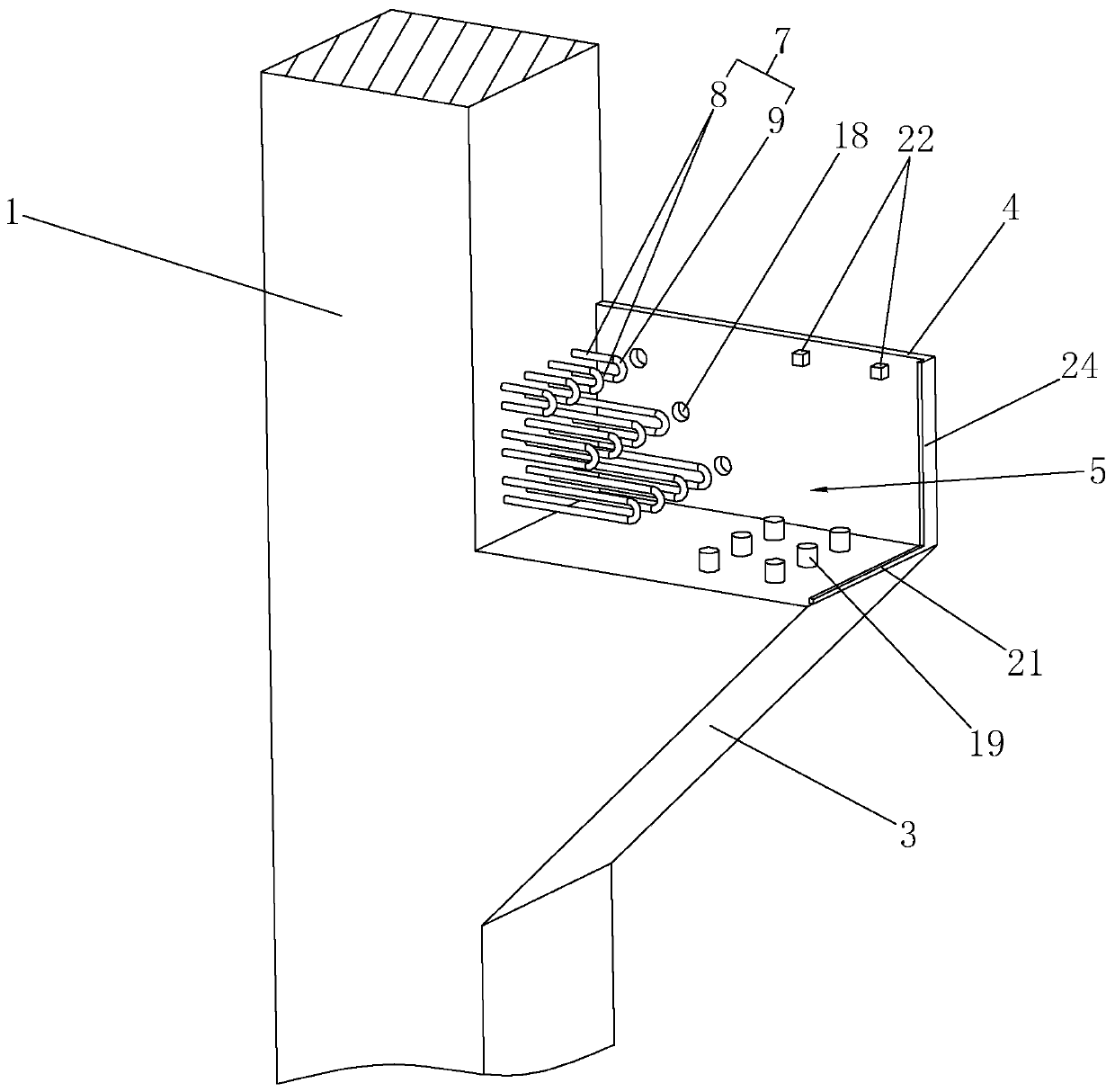

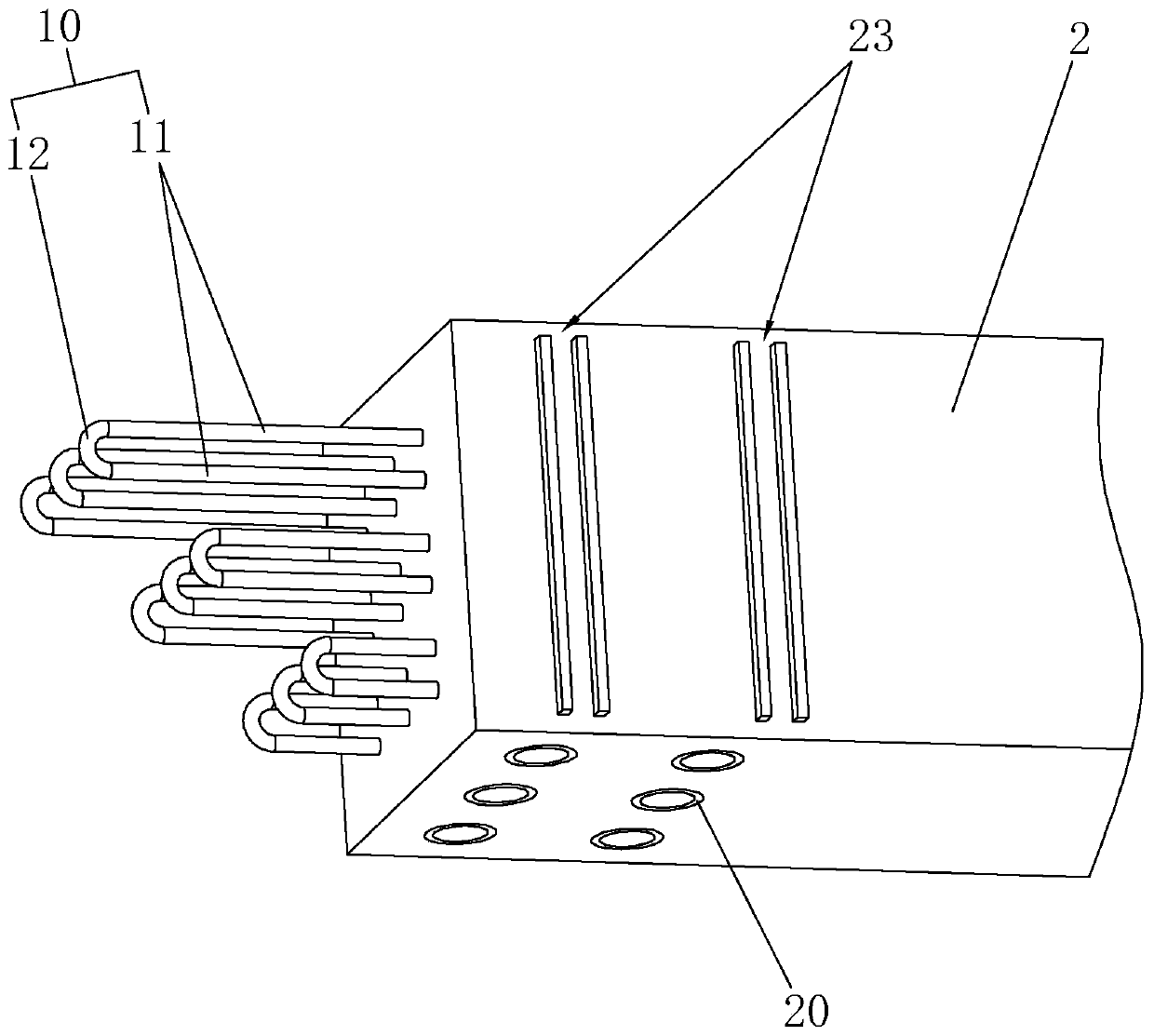

[0040] Such as figure 2 As shown, the side of the precast concrete column 1 facing the installation groove 5 is provided with three rows of column connectors 7 in a rectangular array, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com