Heat preservation and fire prevention integrated template and preparation and installation method thereof

A formwork and thermal insulation technology, which is applied in manufacturing tools, solid waste management, building components, etc., can solve the problems of the influence of floor exterior wall construction, poor thermal insulation effect of buildings, and high energy consumption, so as to save construction steps and raw materials , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

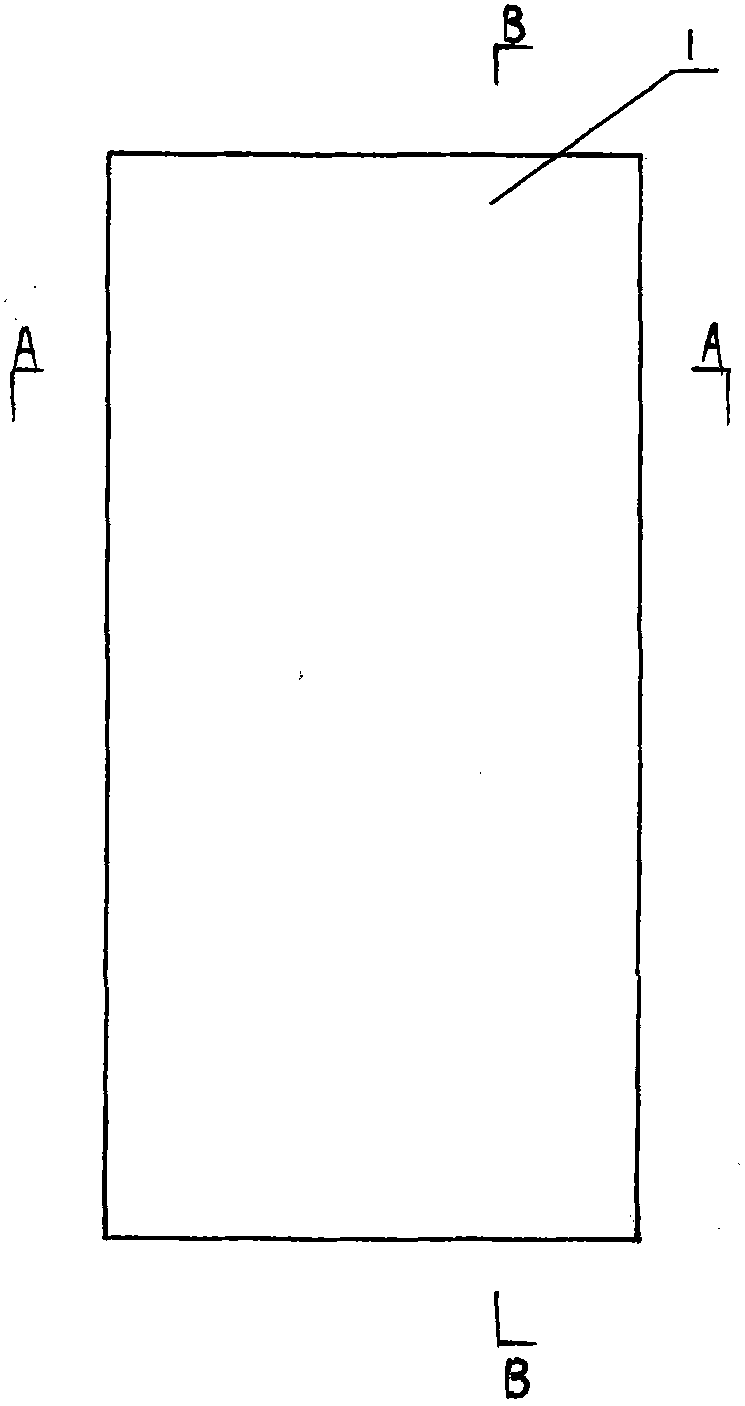

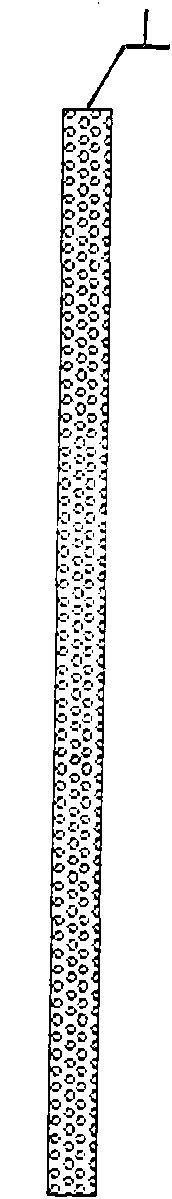

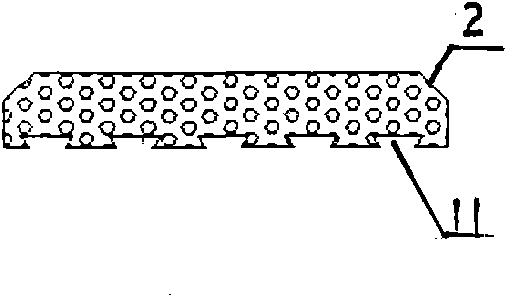

[0037] Such as Figure 1 to Figure 5 As shown, an integrated formwork 1 for thermal insulation and fire prevention, the weight components of the materials used are: 215-220 parts of cement, 100-105 parts of fly ash, 13-15 parts of granular lightweight thermal insulation materials, 1-1.2 parts of polyvinyl alcohol 0.3-0.4 parts of cellulose ether, 0.4-0.5 parts of dispersible rubber powder, 0.5-0.6 parts of early strength agent, and appropriate amount of water;

[0038] The thermal insulation and fire prevention integrated formwork is in the shape of a square or a rectangle. The thermal insulation and fire protection integrated formwork can be configured on one or both sides of the concrete cast-in-place wall according to the design requirements. It can reach more than 500mm), and can also produce different specifications and board shapes according to the design requirements to meet the needs.

[0039] The thermal insulation and fire pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com