Formwork structure of shear wall corner joint, shear wall cast-in-situ system and construction method

A technology of shear walls and corners, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, walls, etc., can solve the damage of exterior panels, poor integrity of exterior tiles, and beautiful structure Poor performance and other problems, to achieve the effect of simplifying construction engineering, firm and reliable connection nodes, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

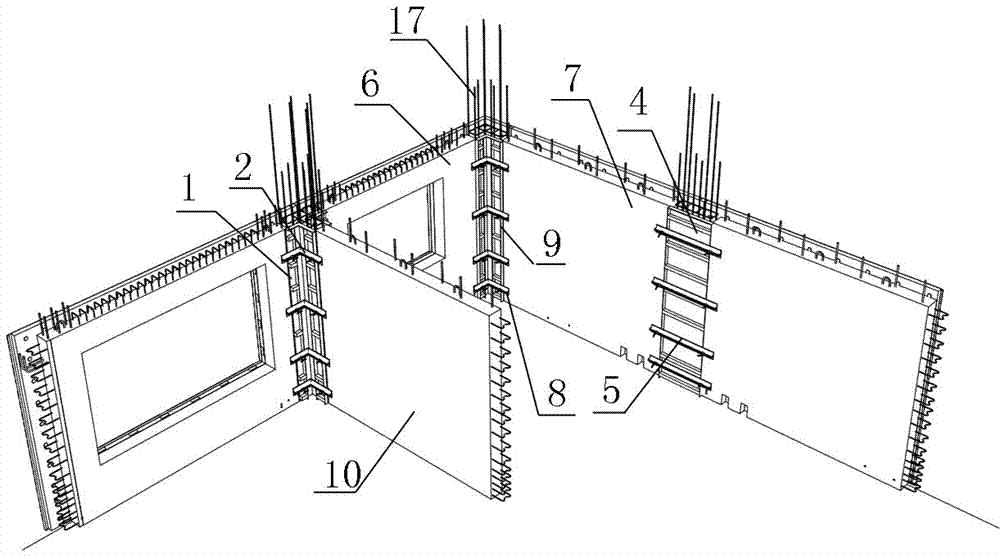

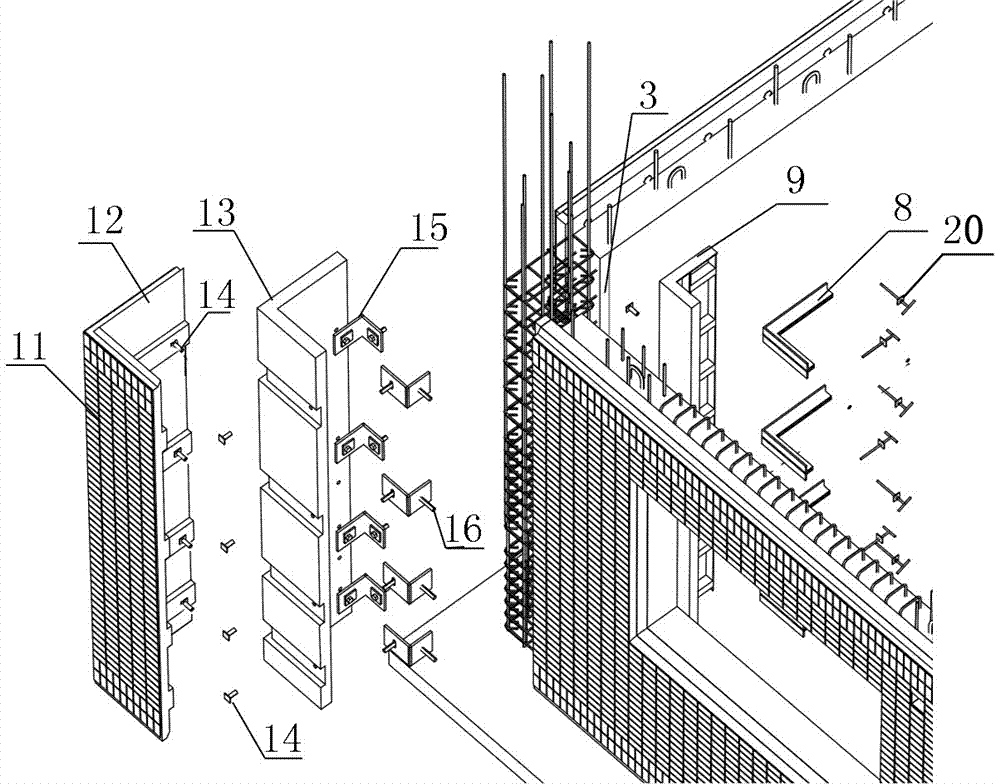

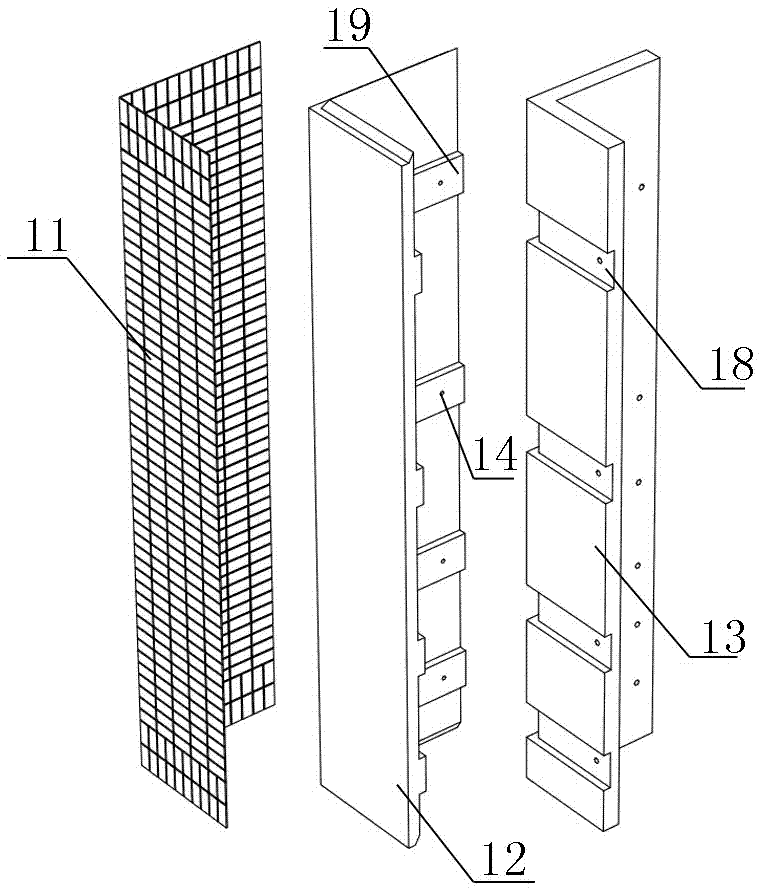

[0038] Such as Figure 1-3 As shown, the formwork structure of the corner joint of the shear wall is set between the transverse prefabricated exterior wall 6 and the longitudinal prefabricated exterior wall 7 on both sides of the corner of the prefabricated shear wall, including The corner outer formwork, the corner inner formwork 9 installed on the inside of the corner of the shear wall, and the corner back flute 8 installed on the inside of the corner inner formwork 9 at intervals along the vertical parallel; and the longitudinal side; the corner outer template is a PCF board, including heat preservation board 13, outer leaf wall board 12 and exterior facing brick 11 arranged in sequence from inside to outside; the outer surface of the heat preservation board 13, along Horizontal through grooves 18 are provided at vertical parallel intervals; horizontally through concrete ribs 19 are provided on the inner side of the outer leaf wall panels 12 at positions corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com