Permanent rigid cement soil enclosure wall for foundation pit and construction method thereof

A foundation pit enclosure, cement-soil technology, applied in water conservancy engineering, infrastructure engineering, excavation and other directions, can solve the problems of prolonging the construction period of the building and complicated construction steps, and achieve the effect of shortening the construction period and reducing the construction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

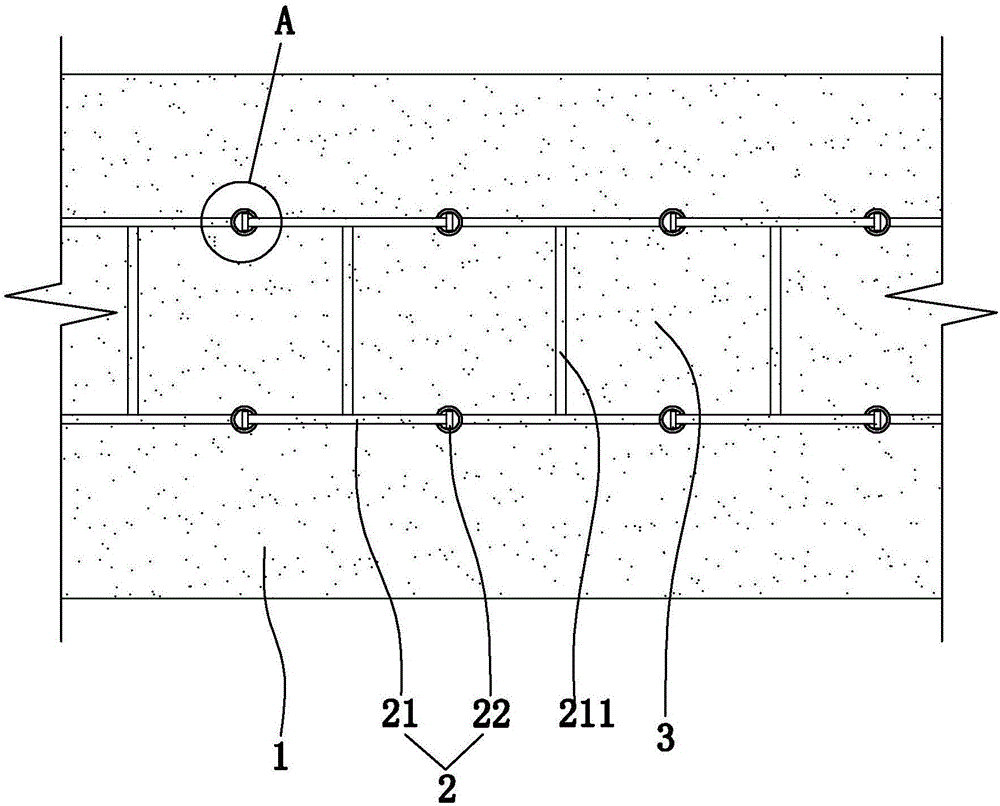

[0025] Embodiment 1: as figure 1 , figure 2 As shown, a cement-soil rigid wall for permanent foundation pit enclosure includes a cement-soil diaphragm wall 1 and a steel composite support structure 2 inserted in the cement-soil diaphragm wall.

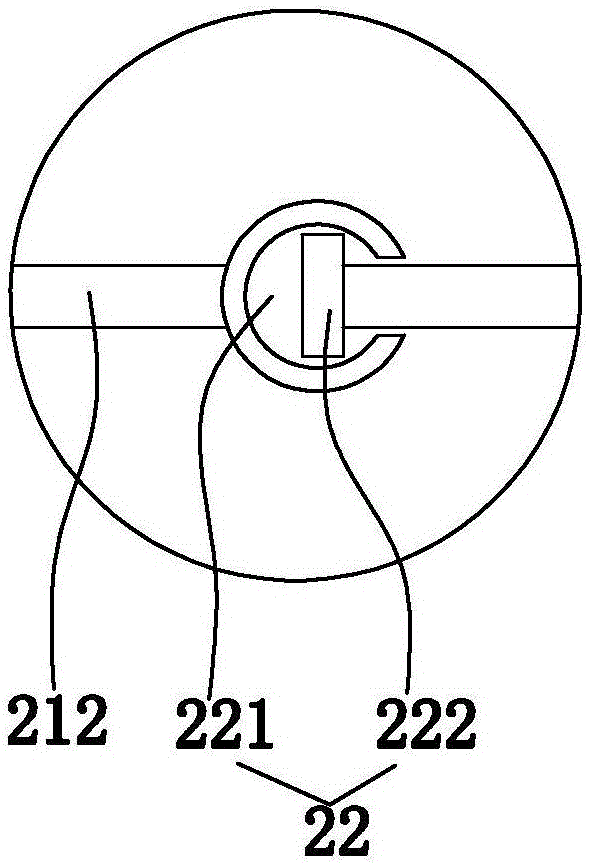

[0026] The section steel combined support structure includes a number of vertical section steels 21 arranged in sequence along the length direction of the cement-soil continuous wall, and two adjacent vertical section steels are connected by a buckle connection structure 22 . The vertical section steel is H section steel. The vertical section steel is set vertically. An accommodating cavity 3 with upper and lower ends open is formed between the webs 211 of two adjacent vertical section steels. The surroundings of the accommodating cavity are closed. The accommodating cavity is filled with cement soil.

[0027] The buckle connection structure consists of a vertical slot 221 arranged on one vertical section steel and a vertical ins...

Embodiment 2

[0031] Embodiment 2, a construction method of a permanent foundation pit enclosure cement-soil rigid wall (the specific structure of the permanent foundation pit enclosure cement-soil rigid wall in this embodiment refers to Example 1), which includes the following steps in turn:

[0032] First, construct a cement-soil continuous wall with a set length along the wall-building direction in the foundation soil layer. In the present embodiment, the set length of the cement-soil continuous wall is 8-12 meters.

[0033] Second, insert the vertical section steel into the cement-soil diaphragm wall one by one along the length direction of the cement-soil diaphragm wall, and when the vertical section steel is inserted into the cement-soil diaphragm wall, the adjacent two vertical sections are connected by a buckle connection structure. Connection, so as to form a continuous steel wall in the cement-soil continuous wall.

[0034] The specific construction process of this step is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com