Patents

Literature

56results about How to "Uniform chamfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

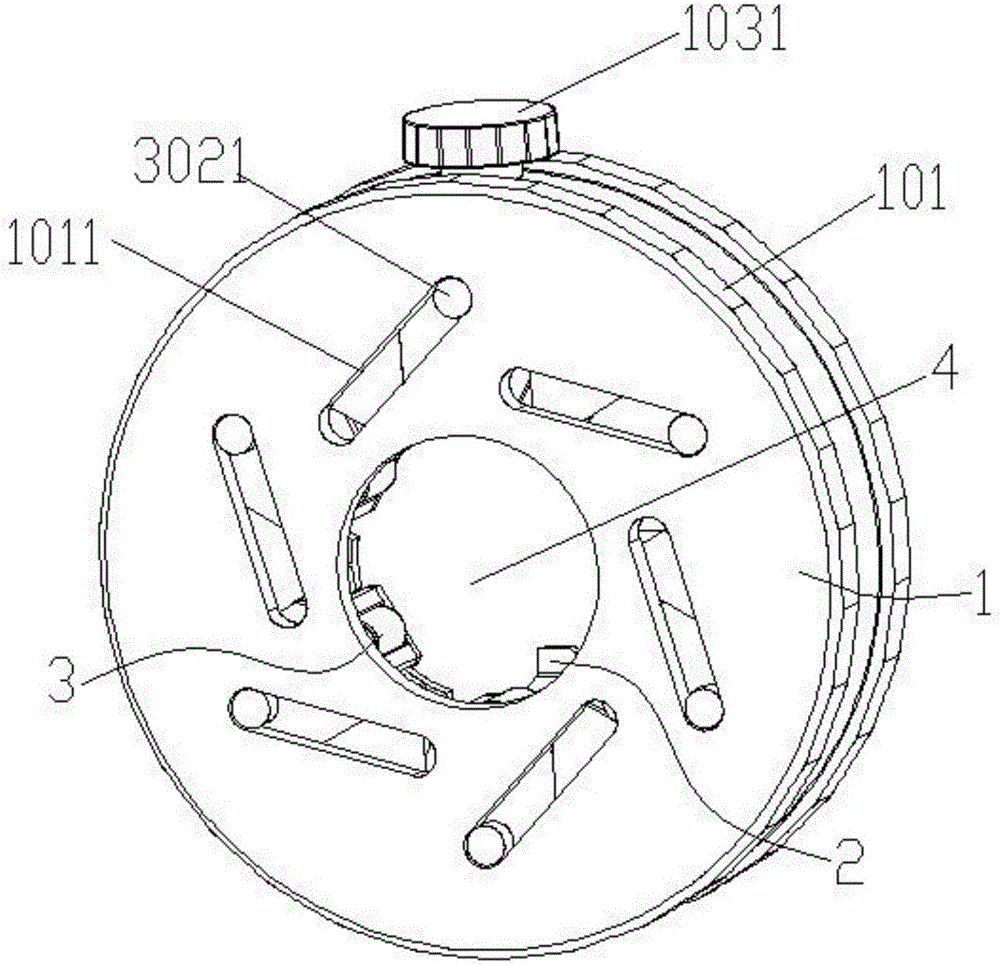

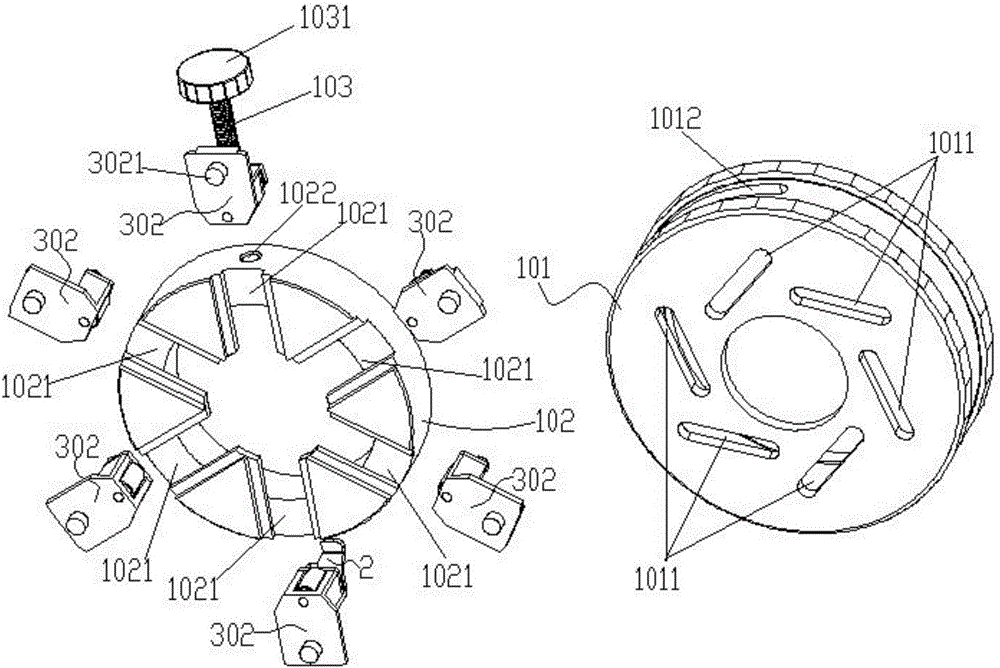

Wheel disc type cable sheath chamfering cutter and chamfering method

InactiveCN106058745ASimple structureSimple and fast operationApparatus for removing/armouring cablesReciprocating motionEngineering

The invention discloses a wheel disc type cable sheath chamfering cutter. The cutter comprises chamfering blades arranged on an annular knife rest and a wire clamping apparatus, wherein the annular knife rest comprises an annular chuck and an annular housing, the wire clamping apparatus can be adjusted to perform reciprocating movement along the radial direction of the annular chuck through a locking apparatus so as to enable the wire clamping apparatus to clamp a cable to be chamfered, and the cutter can move spirally relative to the cable so as to enable the chamfering blades to perform chamfering on the end sheath of the cable. The operation is simple, cables with different wire diameters can be chamfered, the chamfering depth is uniform and is adjustable and controllable, and the safety and the reliability are high. The invention further discloses a method for performing cable chamfering by use of the cutter. First of all, the wire clamping apparatus is adjusted through the locking apparatus so as to clamp the end of the cable to be chamfered, then the cutter is rotated and moved along the circumferential direction of the cable or the cable enables a cutting portion to be in contact with and cut the end sheath of the cable, and thus the end sheath of the cable is chamfered. The chamfering efficiency is high, and a wire core is protected.

Owner:GUANGZHOU PANYU CABLE WORKS

Spectacle lens chamfering machine

InactiveCN101284366AClose contactUniform chamferEdge grinding machinesBonded abrasive wheelsElectric machineryEngineering

The invention relates to a chamfering machine for spectacle lens. The chamfering machine comprises a chamfer grinding wheel combination, two lens clamping chucks, a motor, a grinding wheel motor, a flume, a driving belt, a machine head, a casing and a switch. The two lens clamping chucks are fixed at the top of the machine head; the rear end of one lens clamping chuck is connected with the motor and a clamping nut is arranged on the rear end of the other lens clamping chuck. The chamfering grinding wheel is fixed on the casing shaft through nuts, the shaft is connected with the grinding wheel motor through a second driving belt, and the second driving belt and the grinding wheel motor are both arranged at the bottom of the casing; a slide rod is arranged on the upper end of the casing, and the machine head is movably sleeved on the slide rod. An inclined angle Alpha between the shaft and the horizontal direction is 10-20 DEG; the chamfering grinding wheel is formed by a combination of a first grinding wheel, a second grinding wheel and a rag wheel engaged mutually, and is fixed on the shaft to form a rimmed lens special notch and a rimless lens special notch. By adopting the inventive structure, the chamfering machine has the advantages that the chamfering operation is convenient and easy to learn, the structure is simple, the maintenance is convenient and the price is moderate.

Owner:陆雄杰

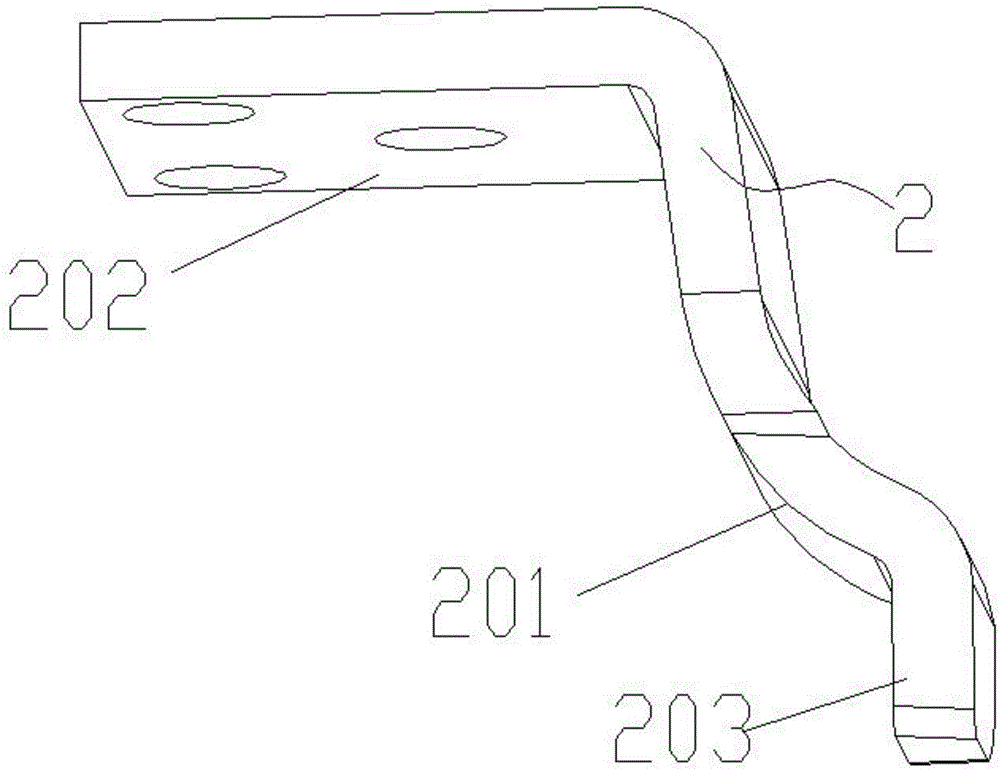

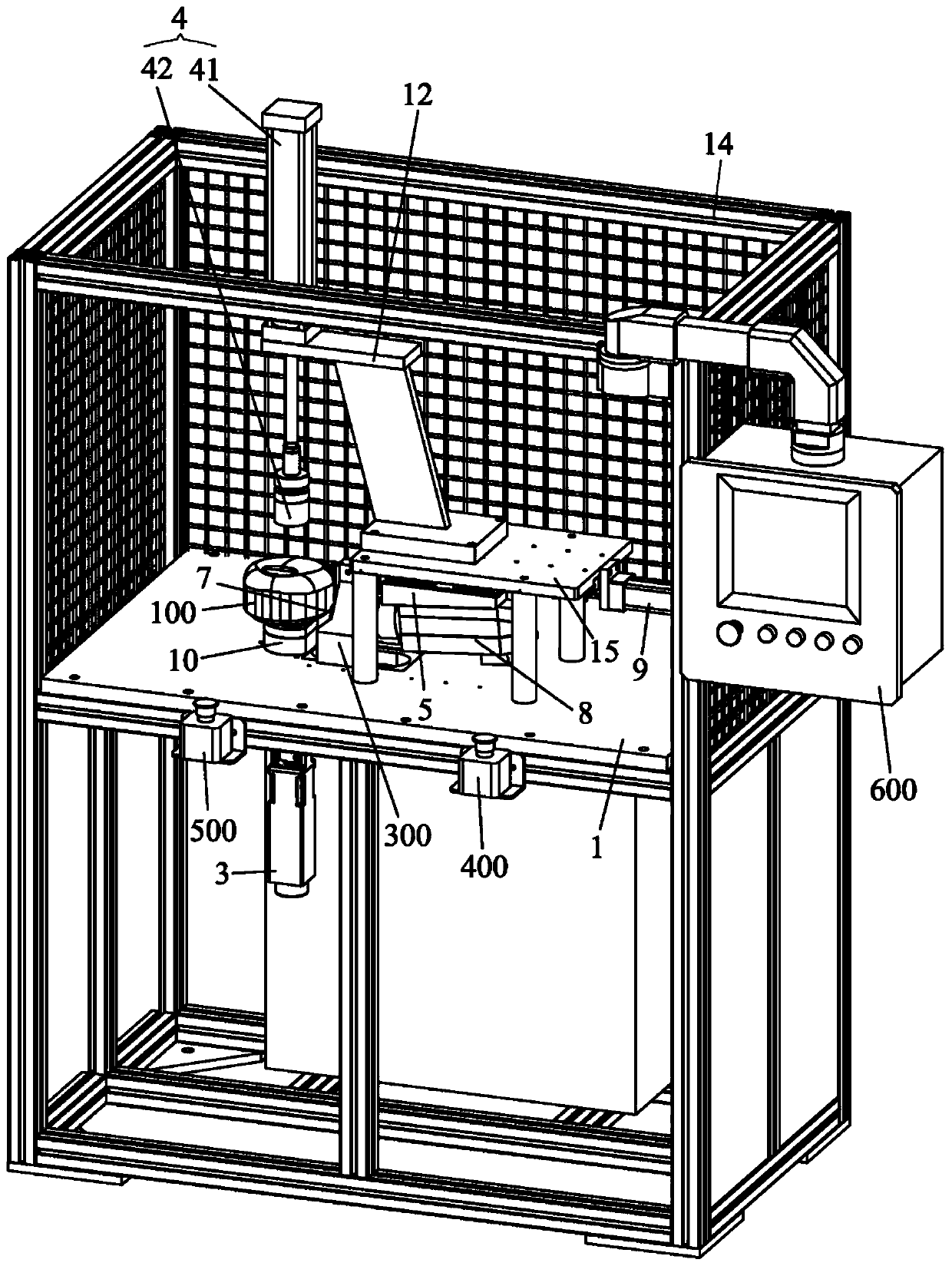

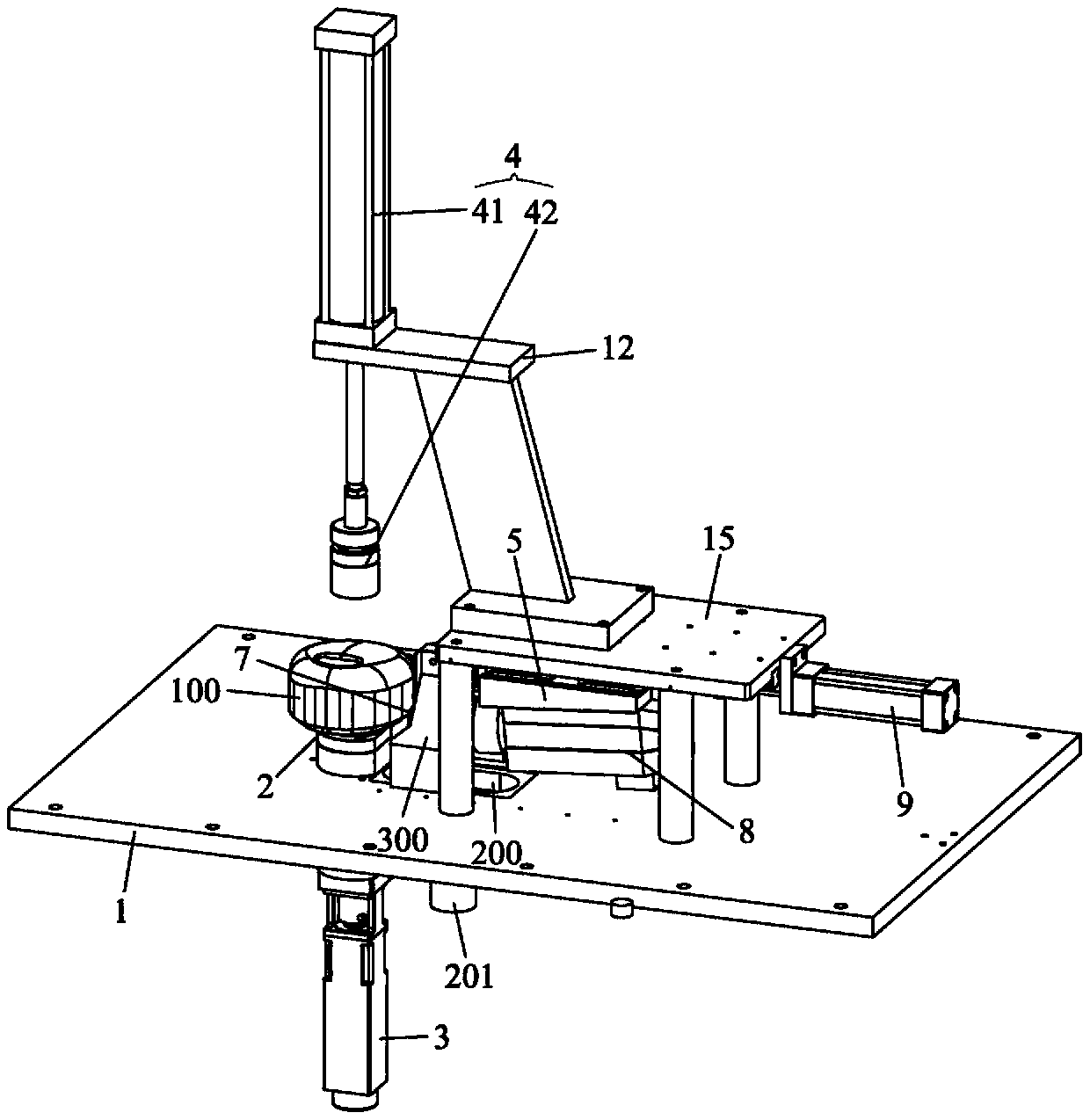

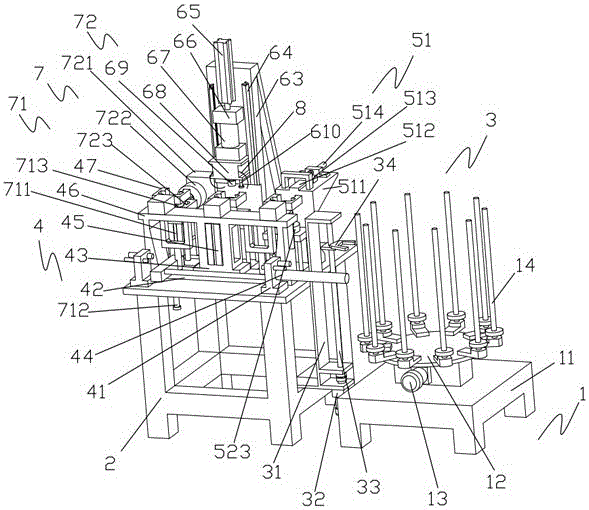

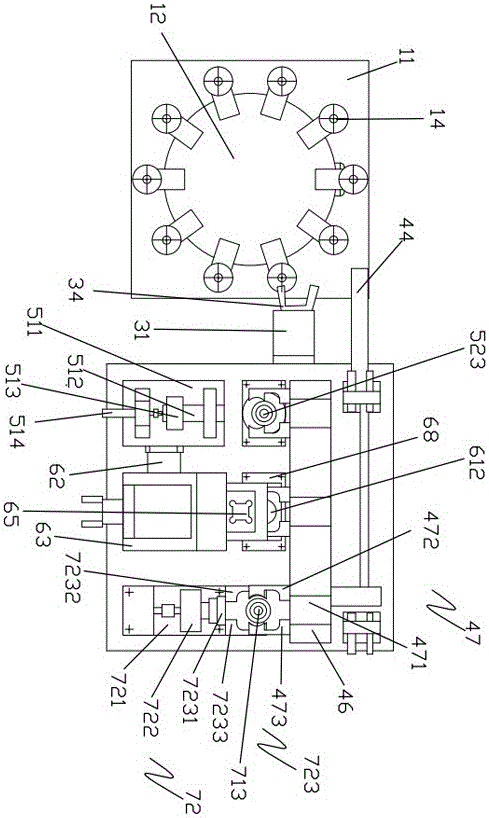

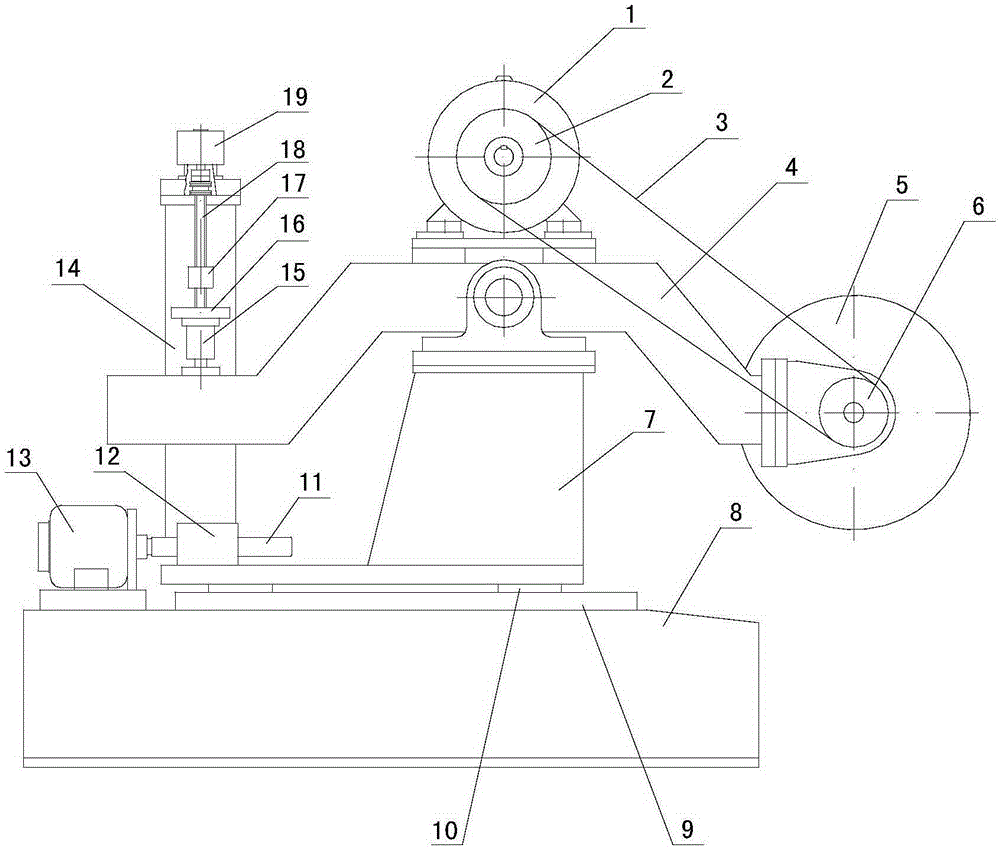

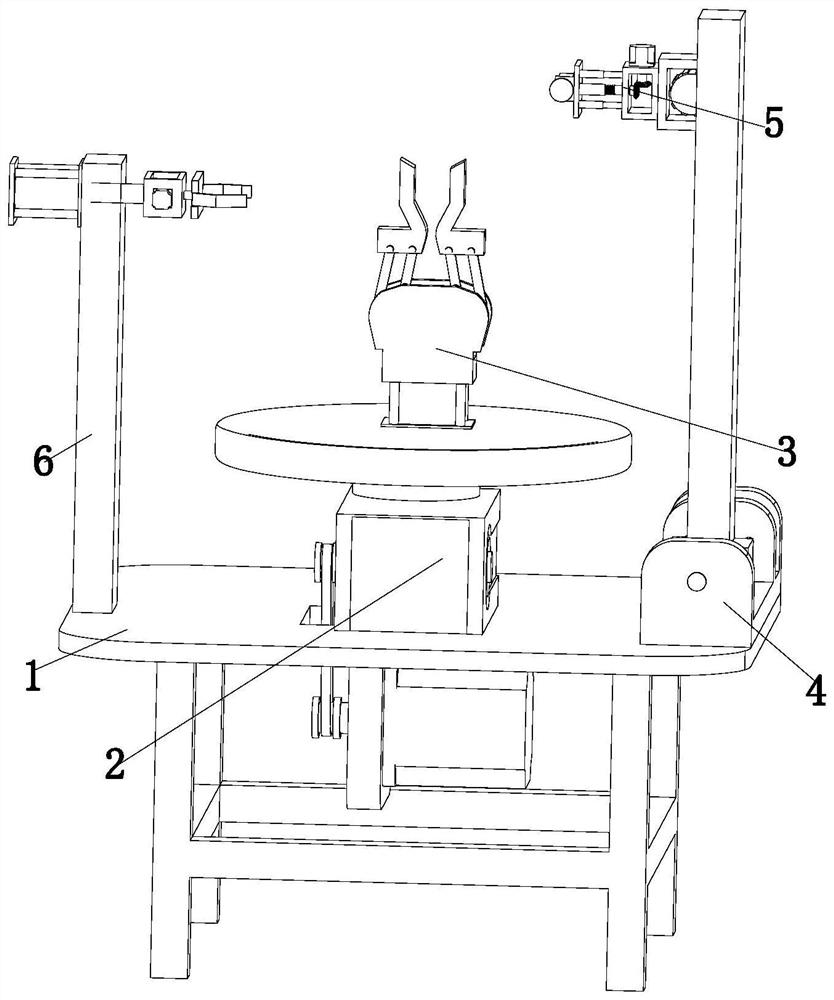

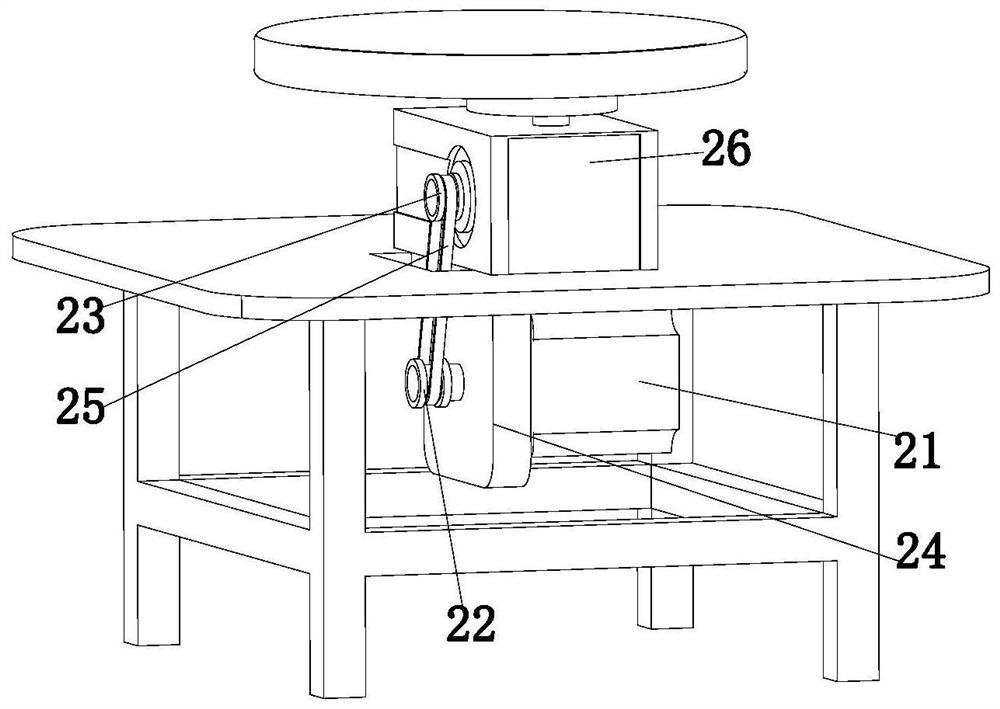

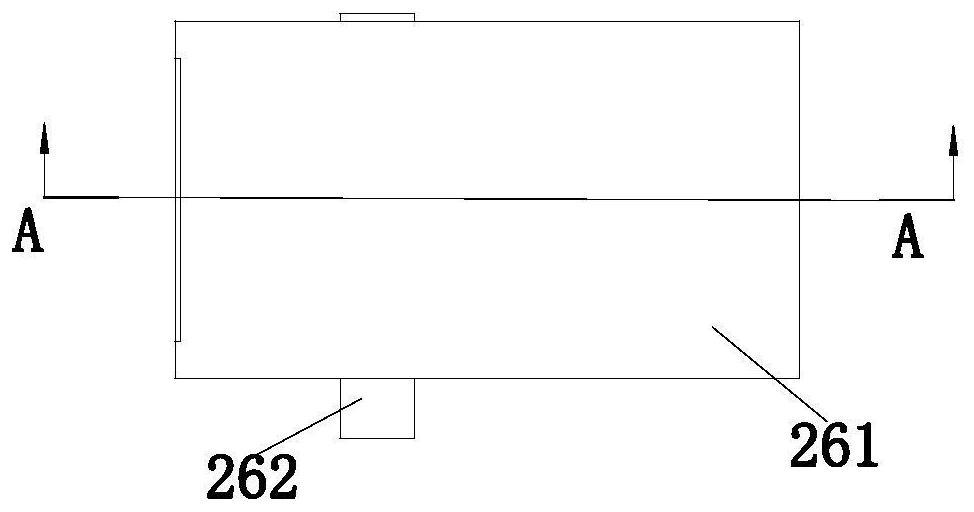

Chamfering machine

PendingCN110238456AUniform chamferImprove chamfer qualityFeeding apparatusDriving apparatusProcessing costEngineering

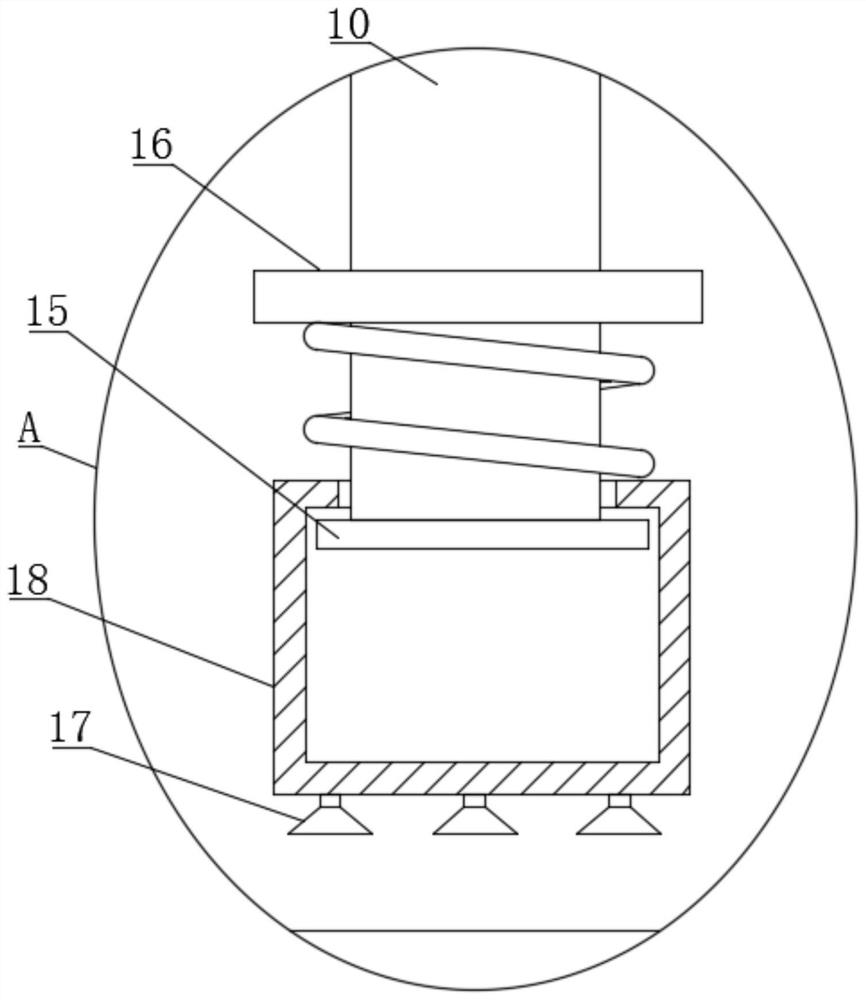

The invention discloses a chamfering machine. A limiting part is arranged on a movable base or a chamfering tool; the movable base is driven by a feeding device to drive a cutting portion and the limiting part of the chamfering tool to respectively and tightly abut against a chamfering area of the end face of a workpiece and an area, close to the end face, of the side surface of the workpiece; a supporting table drives the workpiece to rotate under driving by a first drive device during processing; a tool rod drives the chamfering tool to rotate under driving by a second drive device and performs chamfering on the to-be-chamfered area of the end face, abutting against the chamfering tool, of the workpiece; in the chamfering process, due to the fact that the limiting part and the area, close to the end face, of the side surface of the workpiece are against and slide relatively, the chamfering size of the to-be-chamfered area of the end face of the workpiece can be controlled by the chamfering tool, so that the uniform chamfering of the to-be-chamfered area of the end face of the workpiece is realized, the chamfering quality is improved, and the chamfering machine is applicable to chamfer and chip removal processing of workpieces in round, elliptical, square or special shapes an the like, universality and efficiency is high, and the processing cost is low.

Owner:周小玲

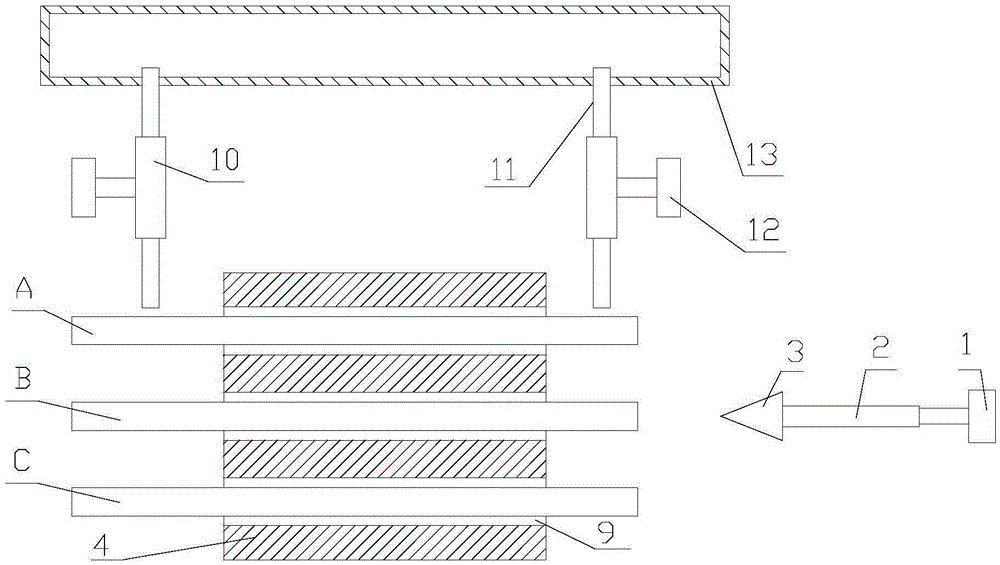

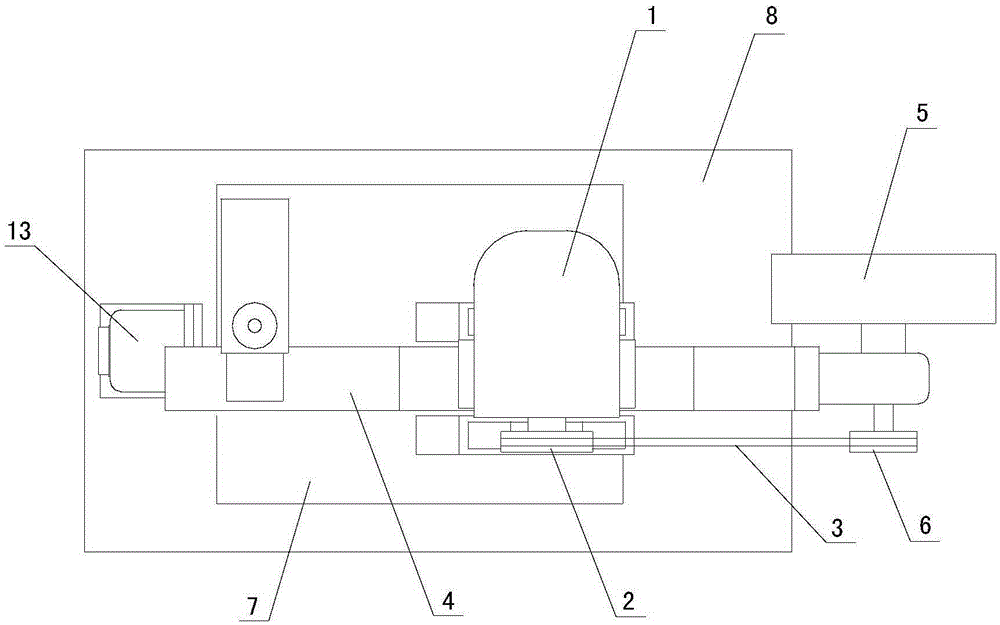

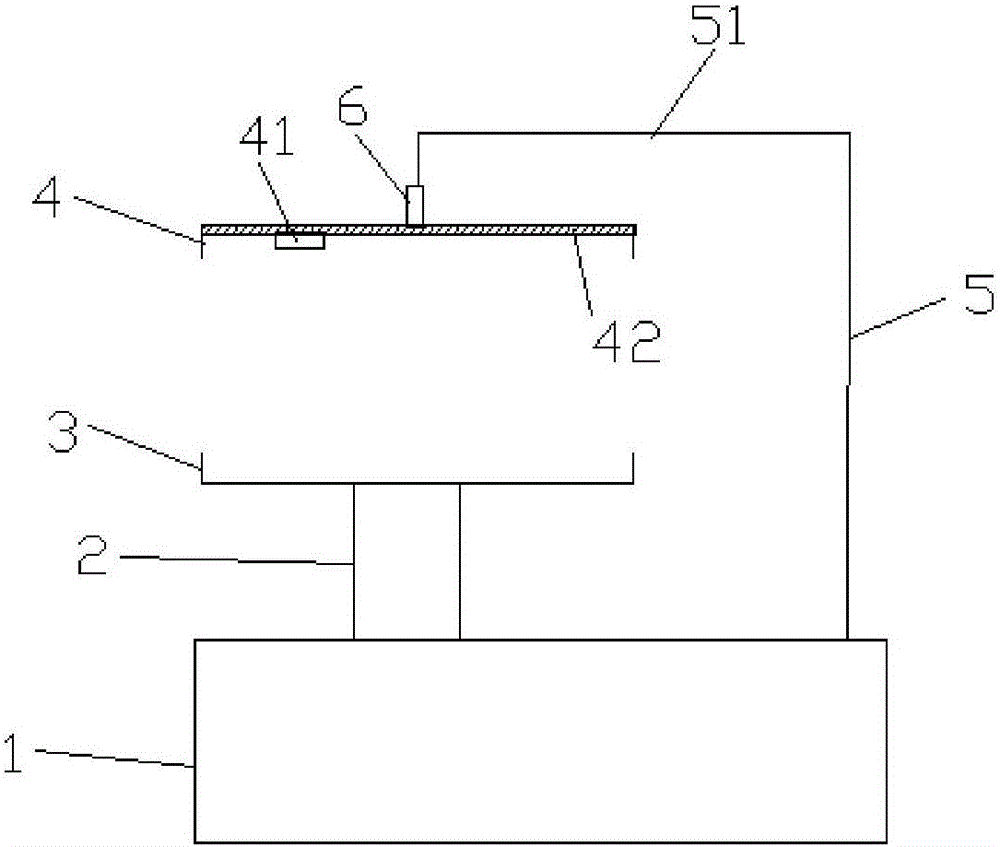

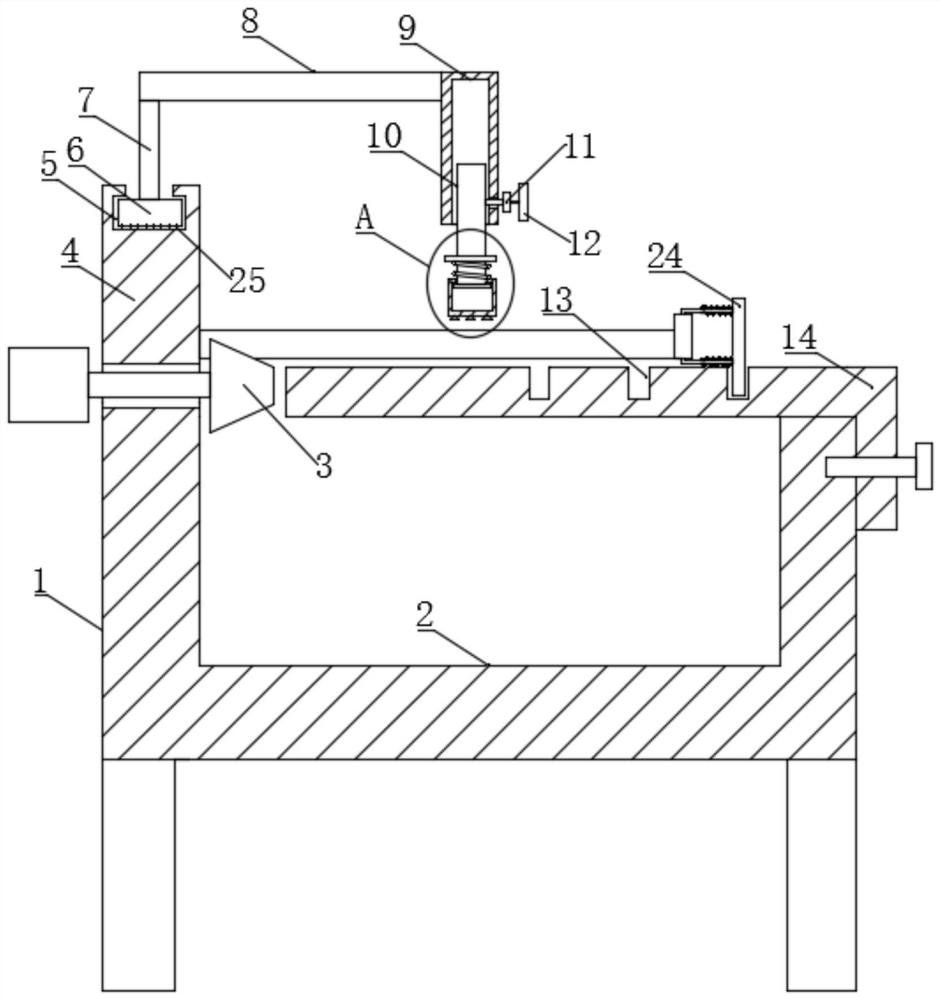

PVC tube stock end planing device

ActiveCN104118004AAvoid uneven milling volumeAvoid uneven chamfer dimensionsMetal working apparatusMilling cutterAutomation

The invention belongs to the field of tube stock machining equipment, and particularly relates to a PVC tube stock end planing device. The PVC tube stock end planing device comprises a machine body and a clamping device used for clamping a tube stock. The machine body is provided with a transmission mechanism, a tube stock conveying mechanism and an angle milling cutter. The transmission mechanism is in transmission linkage with the angle milling cutter. The transmission mechanism drives the angle milling cutter to rotate and drives the angle milling cutter to do circumferential cutting movement along the edge of the end of the tube stock, the conveying direction of the tube stock conveying mechanism is consistent with the axis direction of the angle milling cutter, and the tube stock conveying mechanism can convey the tube stock to the angle milling cutter. According to the PVC tube stock end planing device, the automation degree of machining the end of the PVC tube stock can be further improved, the danger of manual end planing is eliminated, and the product production efficiency is improved.

Owner:LIANSU TECH DEV GUIYANG

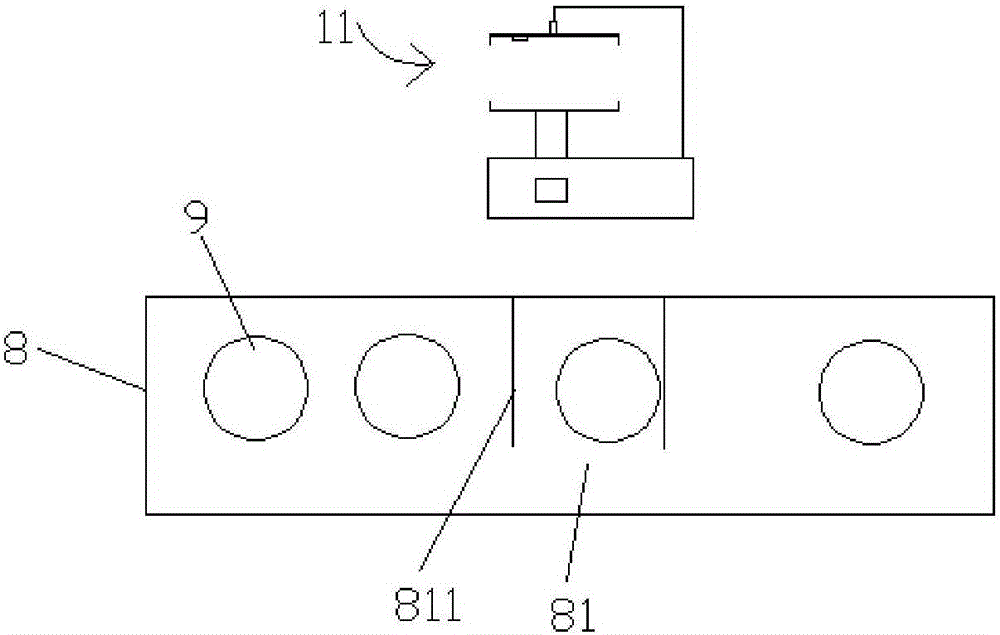

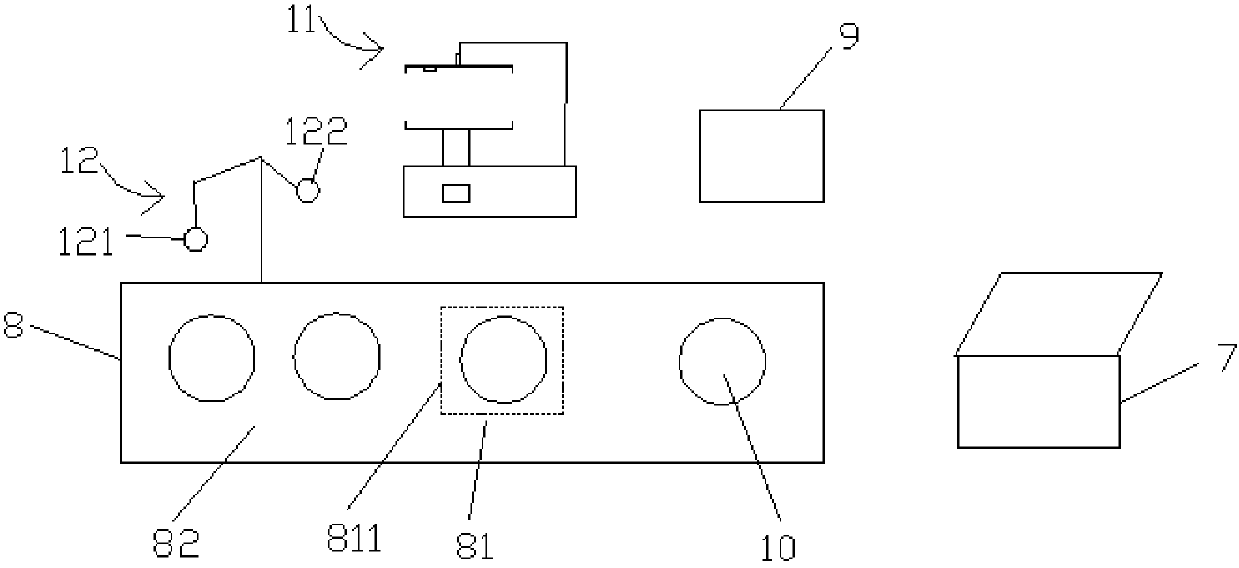

Online burr remover based on ceramic medium chip of high-pressure ceramic capacitor

ActiveCN106002528AUniform chamferIncrease productivityEdge grinding machinesCapacitor manufactureAutomatic transmissionCeramic capacitor

The invention discloses an online burr remover based on a ceramic medium chip of a high-pressure ceramic capacitor. The online burr remover comprises an automatic transmission line and a burr removing device. A burr removing station is arranged on the automatic transmission line, and includes two separation plates; each separation plate can be opened and closed; a gap between the two separation plates is larger than the diameter of the ceramic medium chip, but is smaller than two times of the diameter of the ceramic medium chip; and the burr removing device is arranged on one side of the burr removing station. The burr removing device includes an upper mold, a lower mold, a rotating shaft, a pressure sensor, an electromagnet, a support rod, a rotating bearing and a control panel. After the structure is adopted, and the ceramic medium chip is transmitted to the burr removing station, the electromagnet is electrified, and the ceramic medium chip positioned on the burr removing station is transferred to the lower mold of the burr removing device for removing burrs. After the burrs are removed, the electromagnet is electrified again, and the ceramic medium chip on the lower mold is automatically adsorbed and transferred onto the automatic transmission line again.

Owner:SUZHOU HONGQUAN HIGH VOLTAGE CAPACITOR

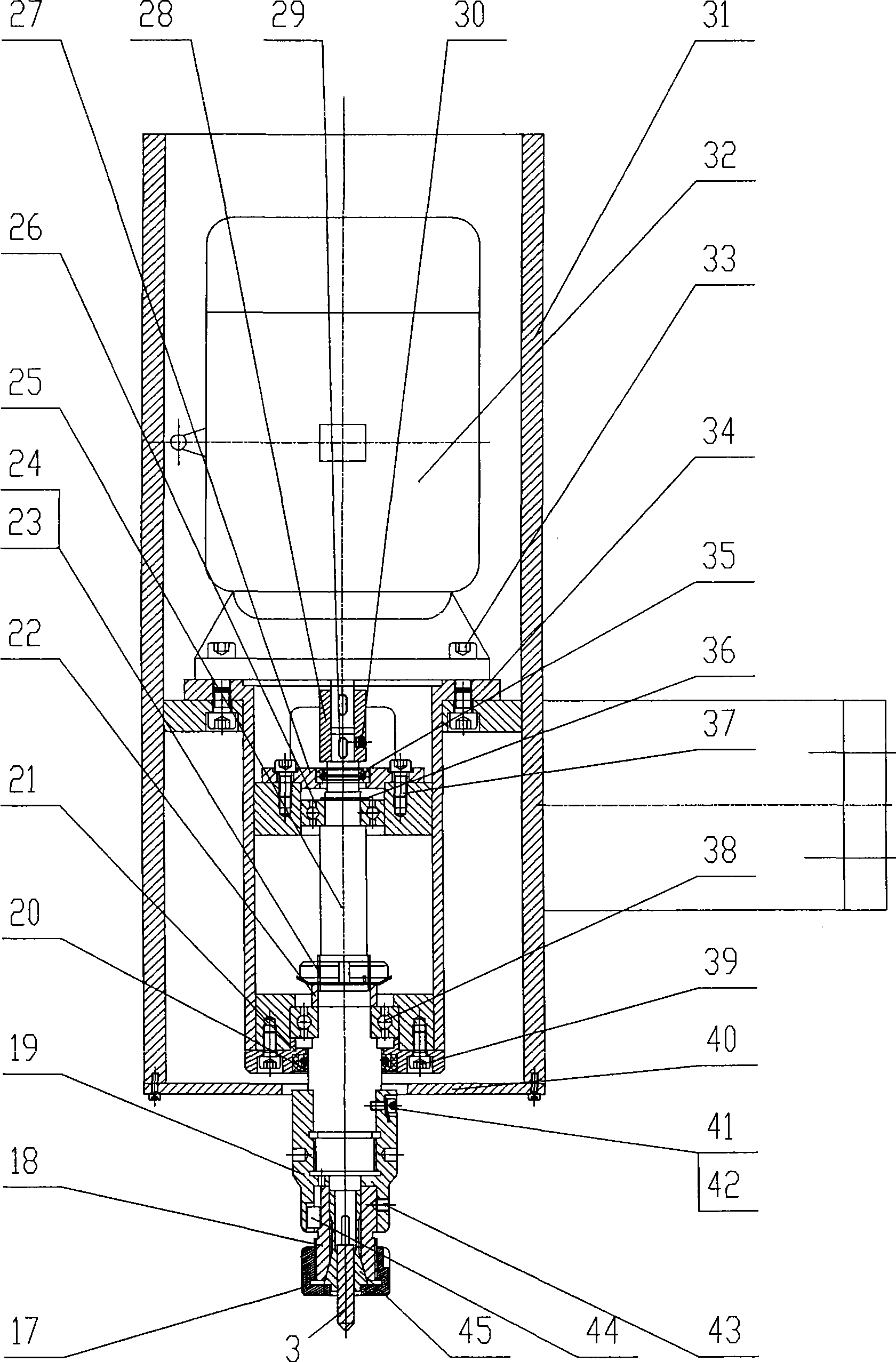

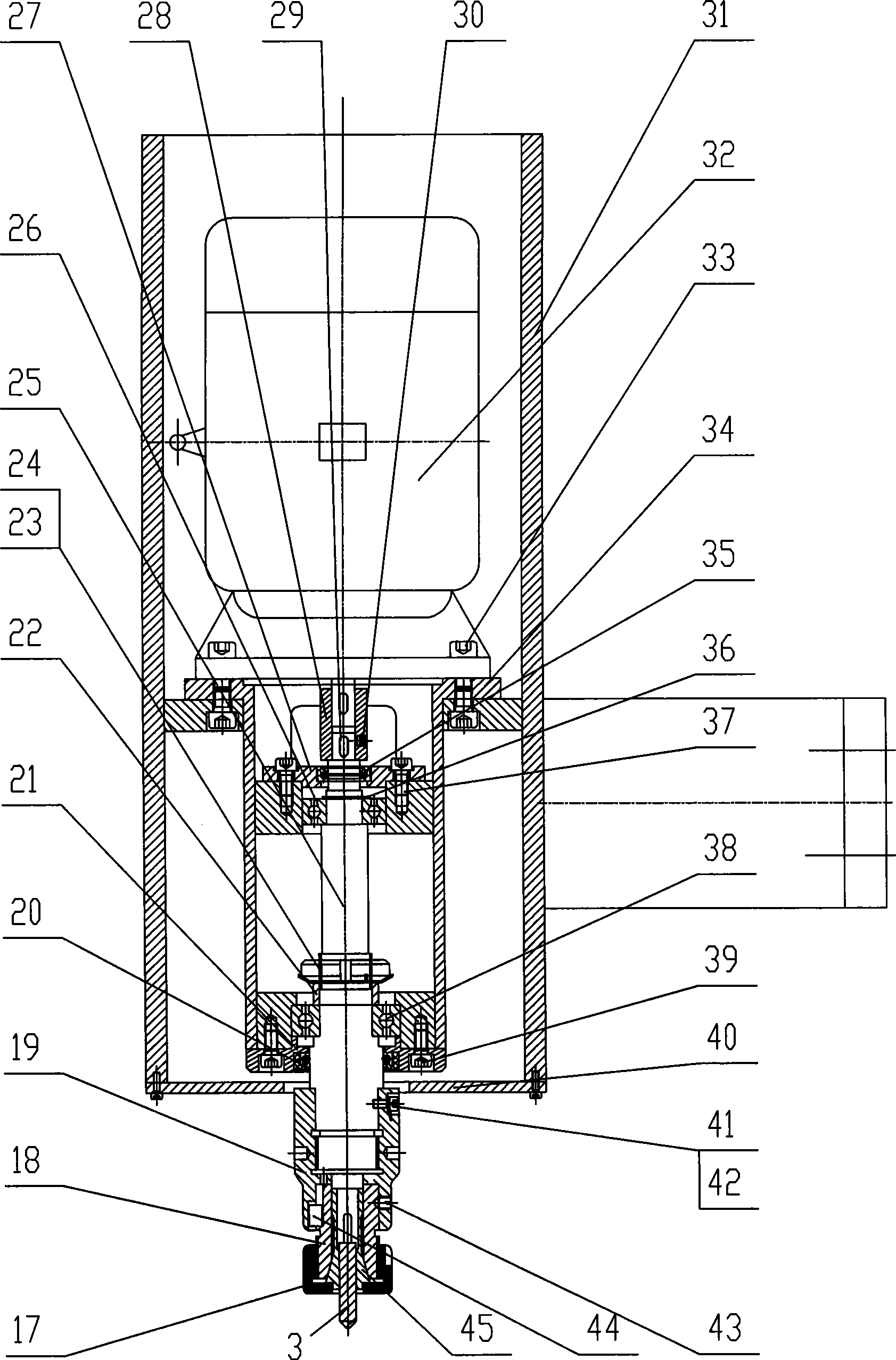

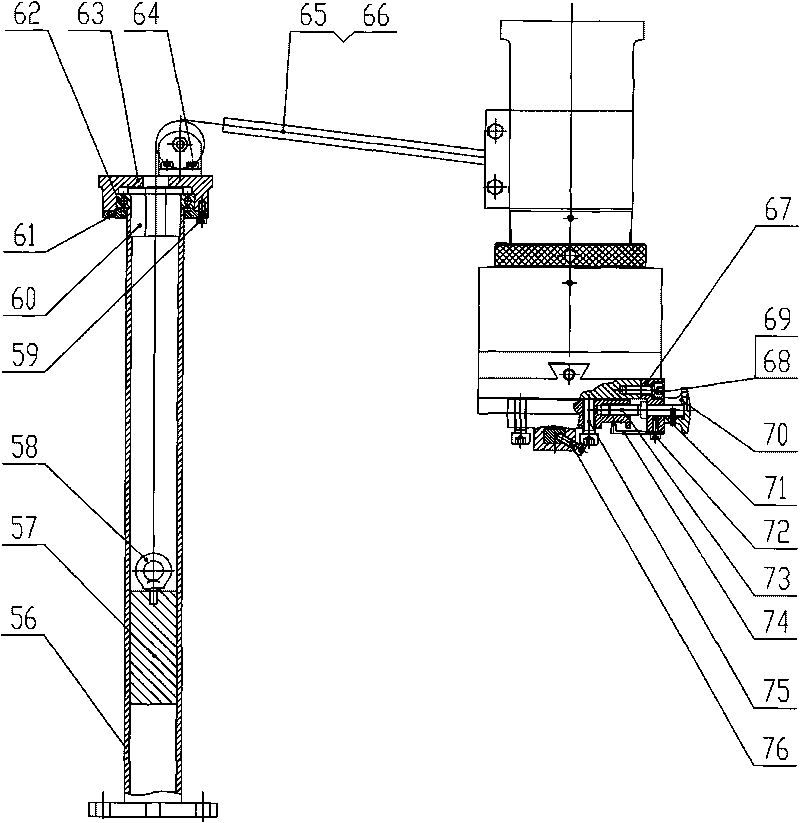

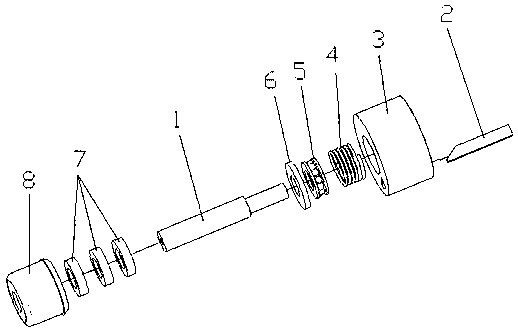

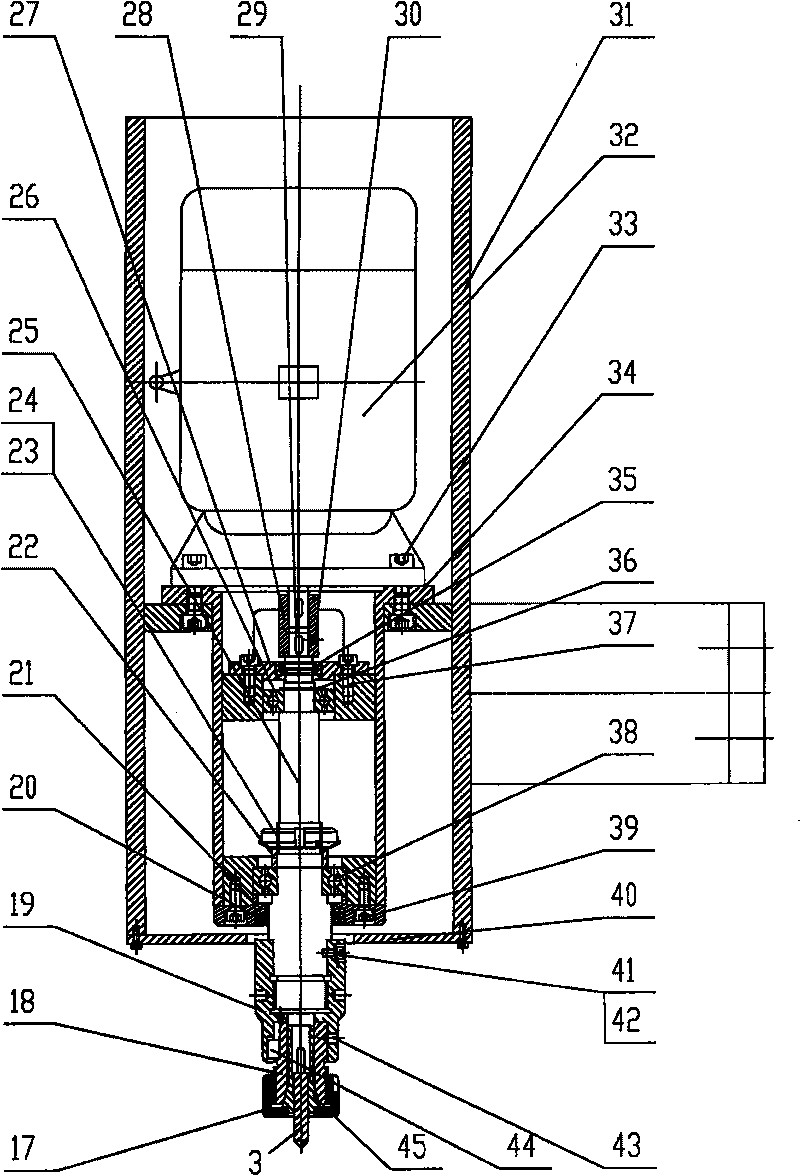

Power unit device of gear-face profiling chamfering device

InactiveCN101422834AReduce use costSimple structureDriving apparatusGear-cutting machinesGear wheelCoupling

The invention relates to a power head device for a copying chamfering device on the end surface of a gear and belongs to the technical field of machinery manufacture. According to the technical proposal provided by the invention, in the power head device, a motor is fixed on a support, the output shaft of the motor is connected with an axis by a sleeve coupling, the upper end and the lower end of the axis are arranged in the sleeve by utilizing an upper bearing, a lower bearing and the bearing seats respectively, and the sleeve is fixed on a plate in the middle of the support by utilizing a flange at the end part of the sleeve; the lower end of the support is provided with a lower cover of a protective case; the lower end of the axis is provided with a joining sleeve; and the joining sleeve is provided with a transitional sleeve. The power head device can realize accurate control on the chamfering size, and the chamfering is carried out in full tooth uniformly along the tooth depth direction, thus improving the chamfering quality.

Owner:江苏南方机电股份有限公司

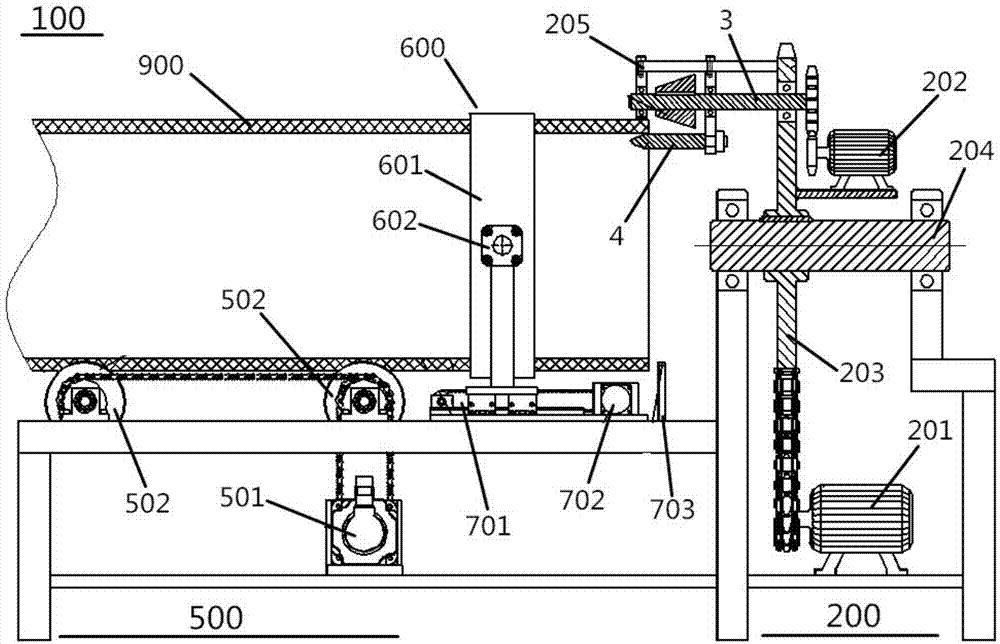

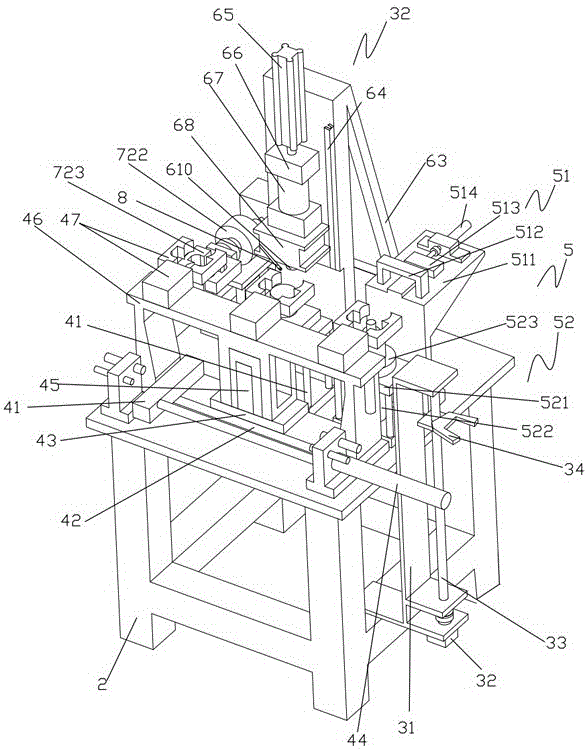

Welding chamfering machine for supporting seat of compressor

ActiveCN106392661AEasy to take outReduce production processing timeOther manufacturing equipments/toolsMetal working apparatusEconomic benefitsEngineering

The invention discloses a welding chamfering machine for a supporting seat of a compressor. The welding chamfering machine comprises a material storage assembly and a rack, wherein a loading mechanism, a moving mechanism, an aligning mechanism, a chamfering mechanism and a turnover mechanism are arranged on the rack; the material storage assembly is connected with the moving mechanism through the loading mechanism; the aligning mechanism, the chamfering mechanism and the turnover mechanism are sequentially arranged at one side of the moving mechanism; and the aligning mechanism is positioned at one side of the loading mechanism. The welding chamfering machine disclosed by the invention can automatically process the supporting seat, so that quantity and workload of operators are reduced, production efficiency is improved, producing processing cost is reduced, and economic benefits are improved; and moreover, moving efficiency of the supporting seat is improved, producing processing time for chamfering is shortened, welding chamfering quality of the supporting seat is improved, production efficiency is improved, scrap iron is prevented from scattering in a production workshop, workload after production of the operators is reduced, production environment is improved, processing efficiency is improved, processing chamfering precision is improved, and chamfering quality of the supporting seat is improved.

Owner:TCL RUIZHI (HUIZHOU) REFRIGERATION EQUIP CO LTD

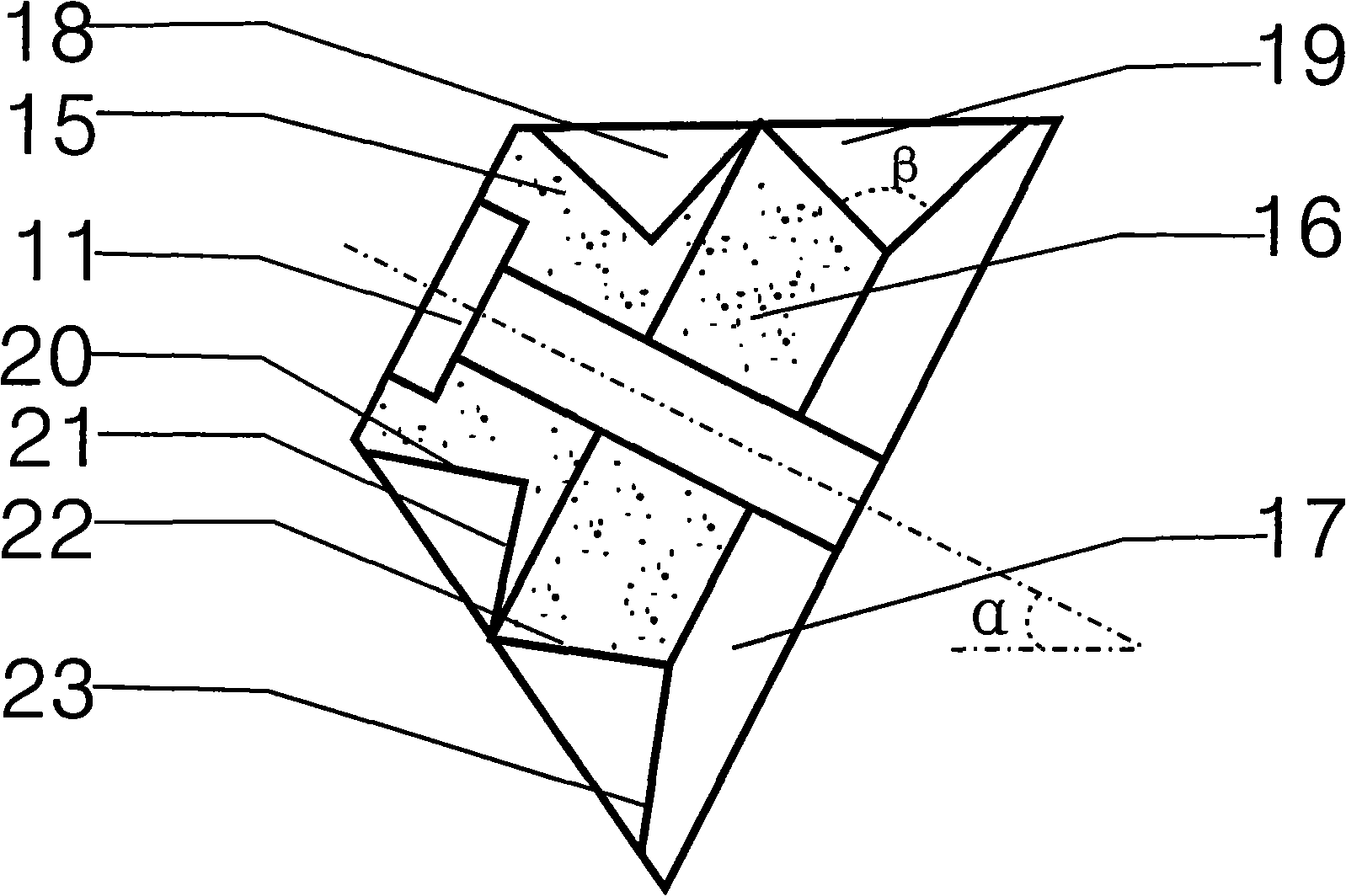

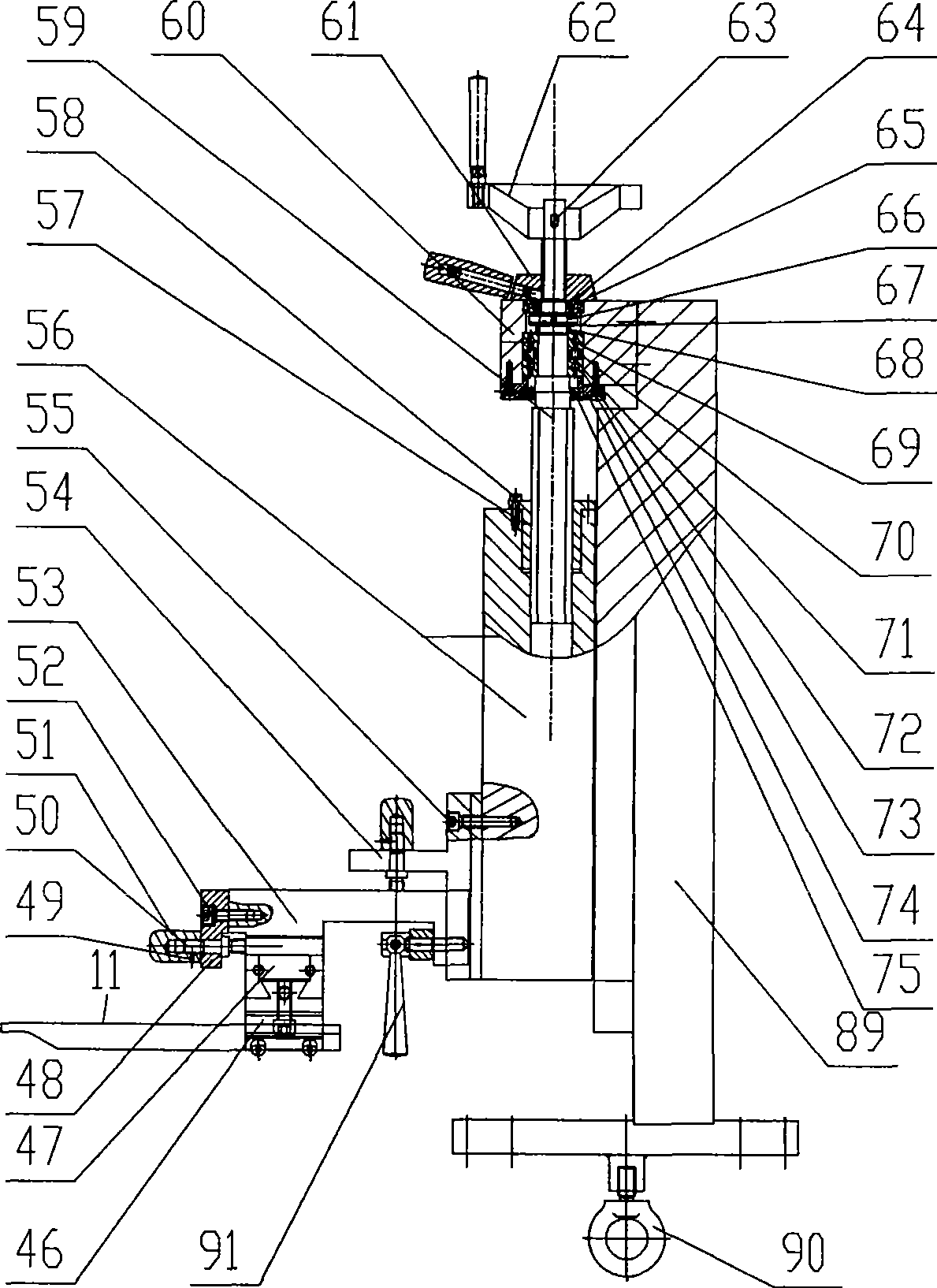

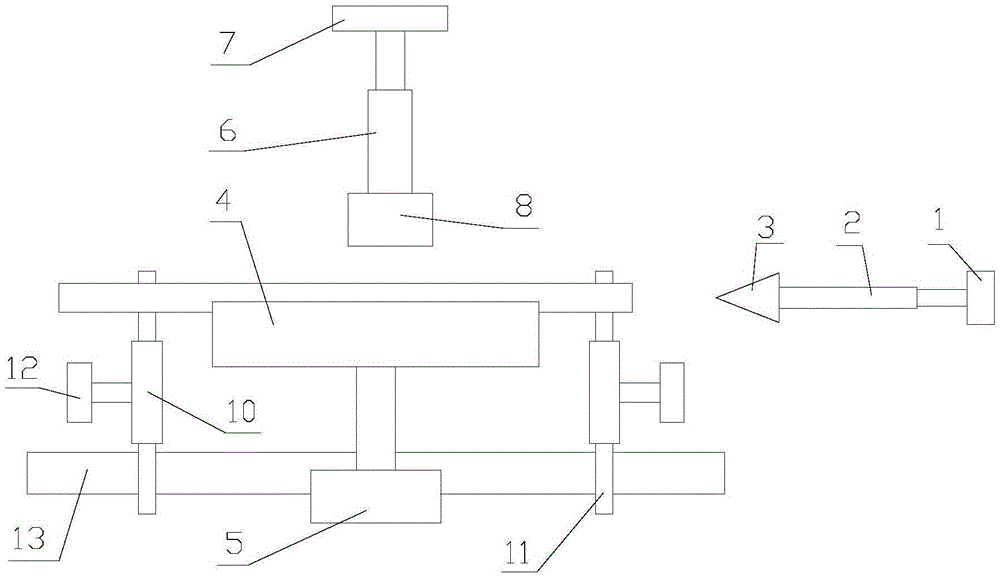

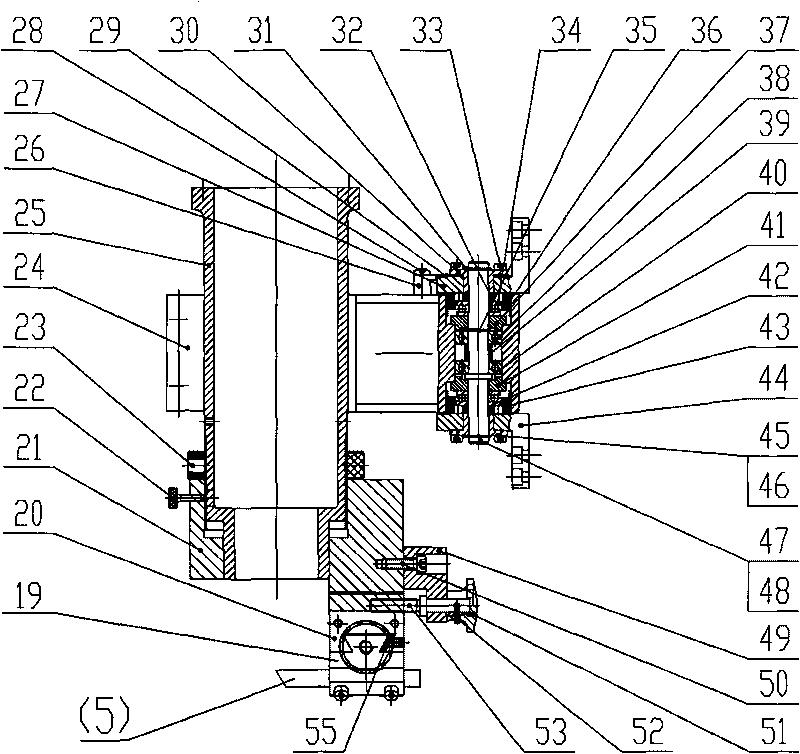

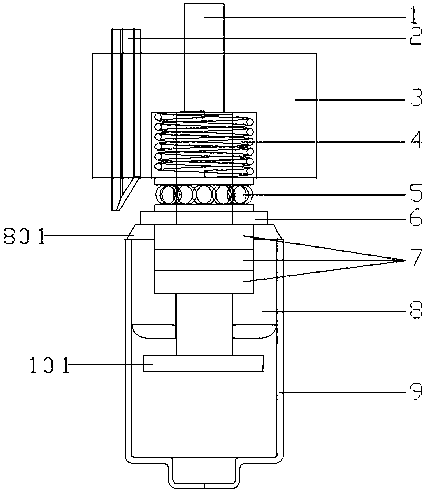

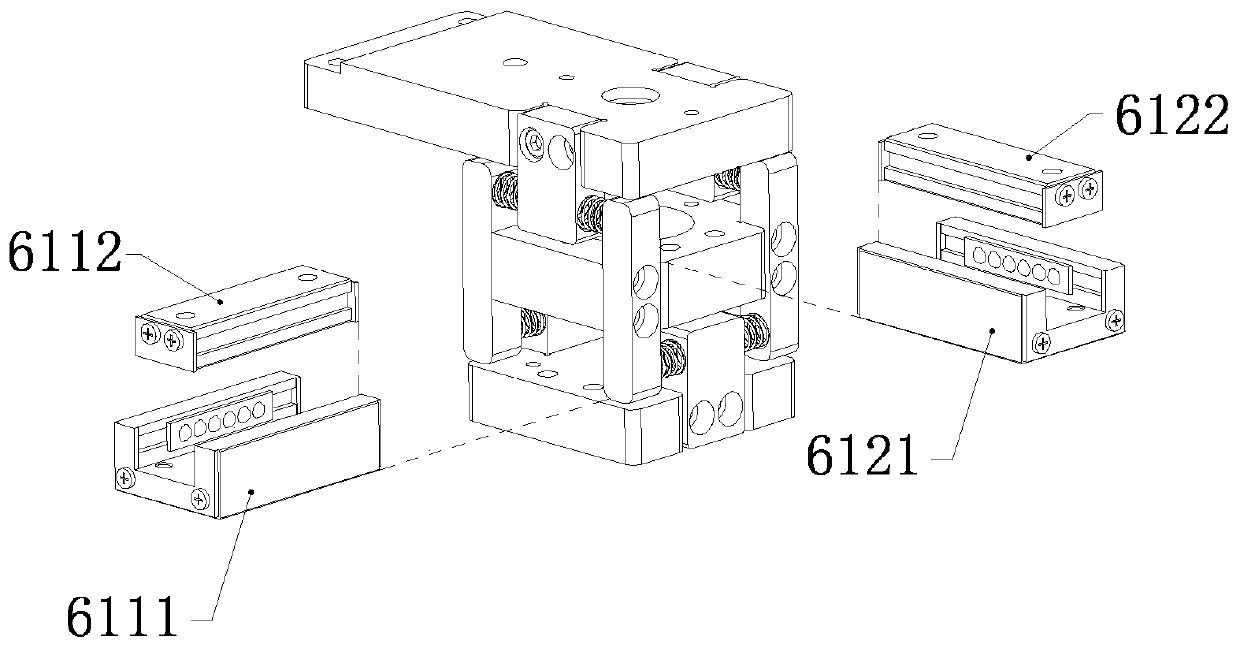

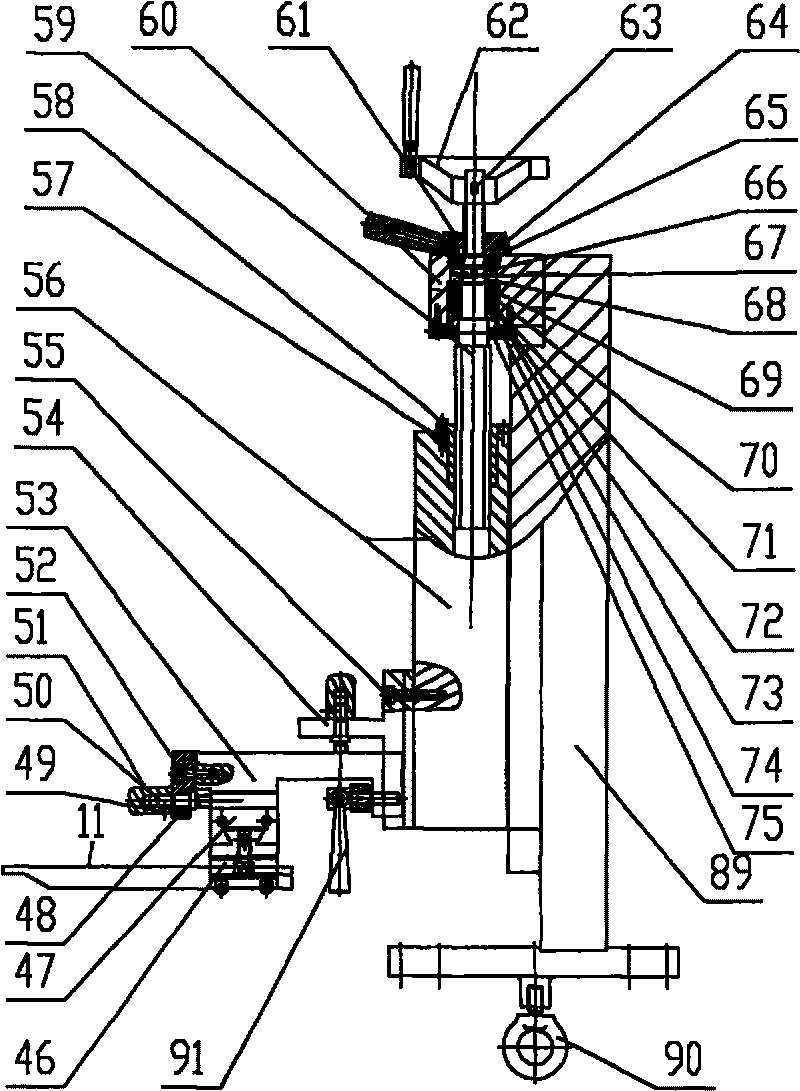

Adjustment mechanism of gear-face profiling chamfering device

InactiveCN101422833AHigh chamfering efficiencyReduce use costGear-cutting machinesGear teethEngineeringDepth direction

The invention relates to a regulating mechanism for a copying chamfering device on the end surface of a gear. According to the technical proposal provided by the invention, in the regulating mechanism, a copying contact is arranged on a Y-direction sliding seat which is connected with an X-direction sliding seat; a stop block is fixed on a lower fixed plate; a fourth screw rod is screwed in the threaded hole of the Y-direction sliding seat; the lower fixed plate is sheathed on the fourth screw rod and is fixed on the X-direction sliding seat; the X-direction sliding seat is connected with a Z-direction sliding seat; a first screw rod is screwed in the threaded hole of the X-direction sliding seat; a middle fixed plate is sheathed on the cylindrical surface of the first screw rod and is fixed on the Z-direction sliding seat; the Z-direction sliding seat is arranged on an upper fixed plate which is sheathed on a third screw rod; the third screw rod is screwed in the threaded hole of the Z-direction sliding seat; the upper fixed plate is fixed on a first slider; a nut is fixed in the inner hole of the first slider; and the first slider is arranged on a regulating frame which is fixed on a slider in a linear guide pair. The regulating mechanism can realize accurate control on the chamfering size, and the chamfering is carried out in full tooth uniformly along the tooth depth direction, thus improving the chamfering quality.

Owner:江苏南方机电股份有限公司

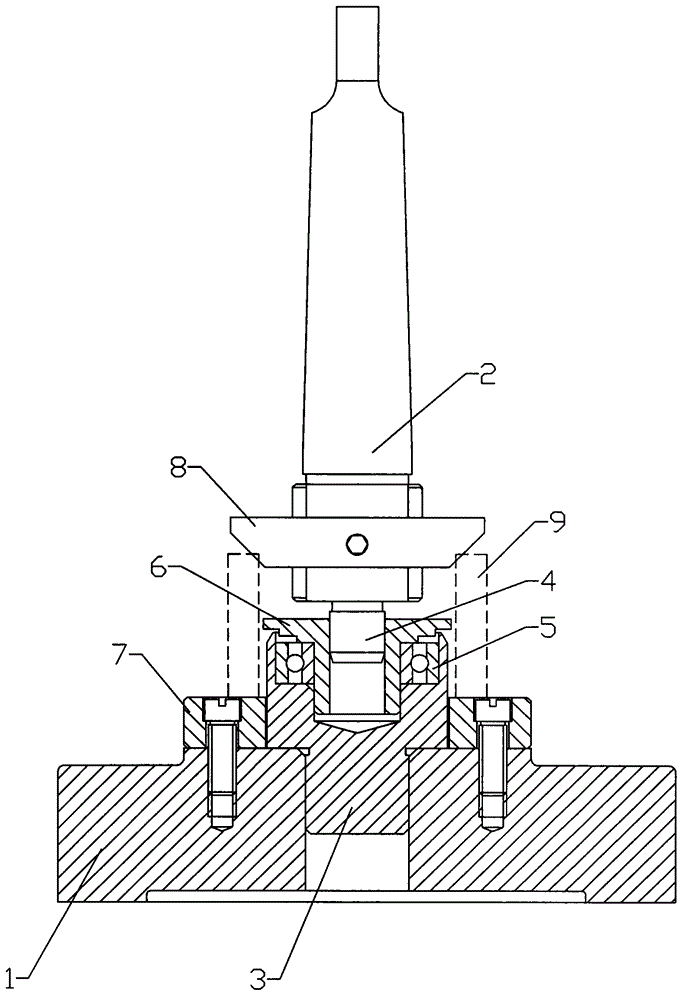

Mechanical part chamfer processing mechanism

InactiveCN104475839AImprove rigidityReduce shakingMilling equipment detailsPositioning apparatusMachining processOperation safety

The invention relates to a mechanical part chamfer processing mechanism. The mechanical part chamfer processing mechanism comprises a workbench and a cutter bar. A positioning device is arranged between the workbench and the cutter bar. The positioning device comprises a positioning shaft, a bearing and a protective cover. The outer ring of the bearing is fixedly connected to the positioning shaft. The inner ring of the bearing is fixedly connected to the protective cover. One end of the cutter bar provided with a cutter is provided with a positioning pin and the positioning pin is fixedly connected to the protective cover of the positioning device so that cutter bar two-point support is formed in processing and thus cutter bar rigidity is improved, cutter shaking is reduced, stability in cutting is improved, fracture is avoided in processing, the processed chamfer has good uniformity and operation safety is high.

Owner:刘彦东

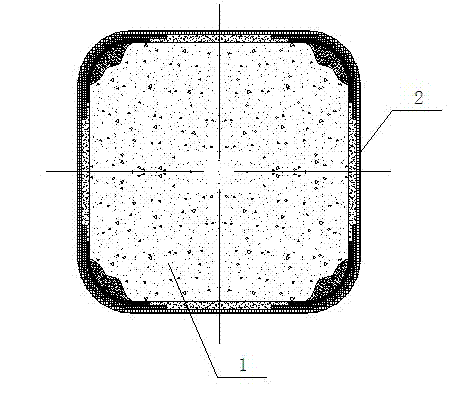

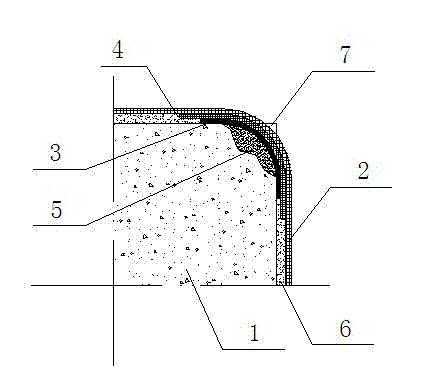

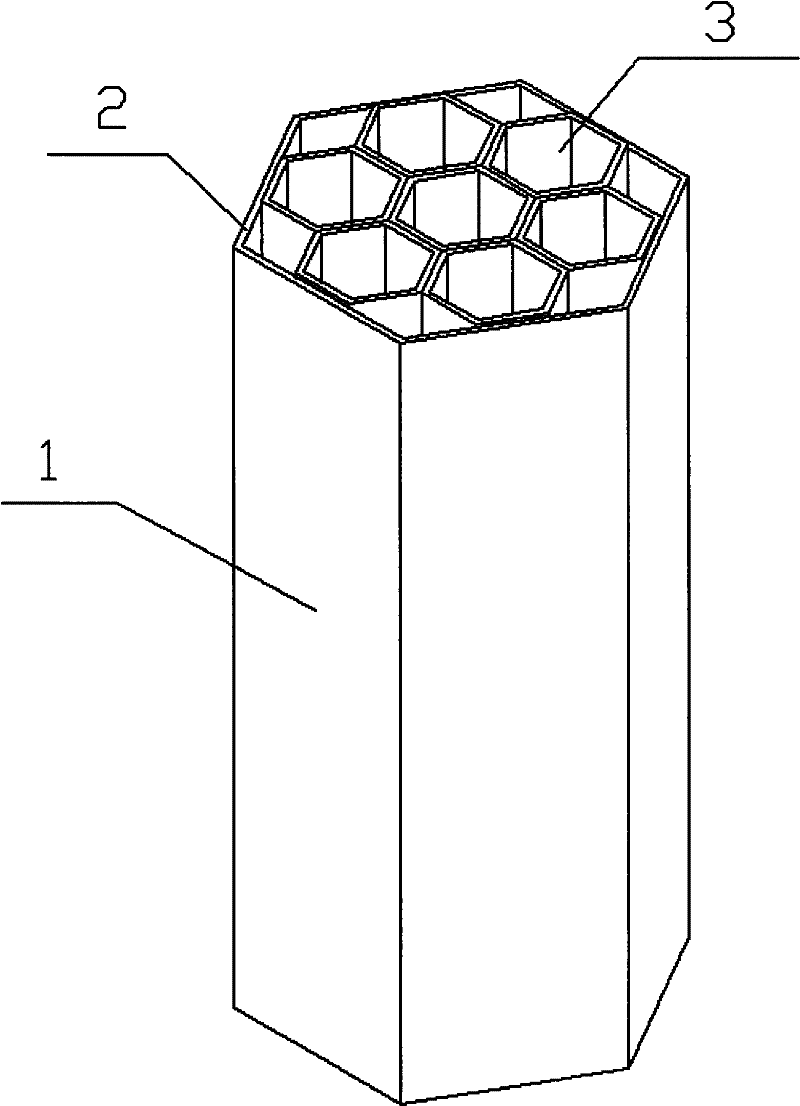

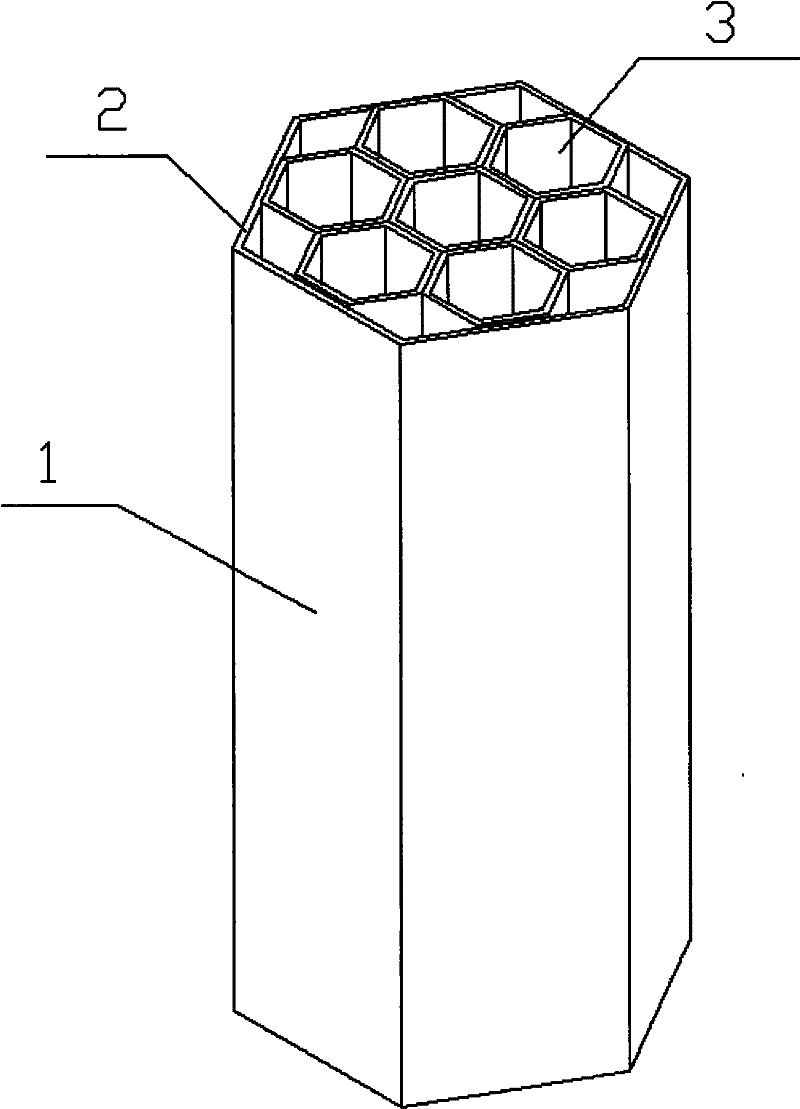

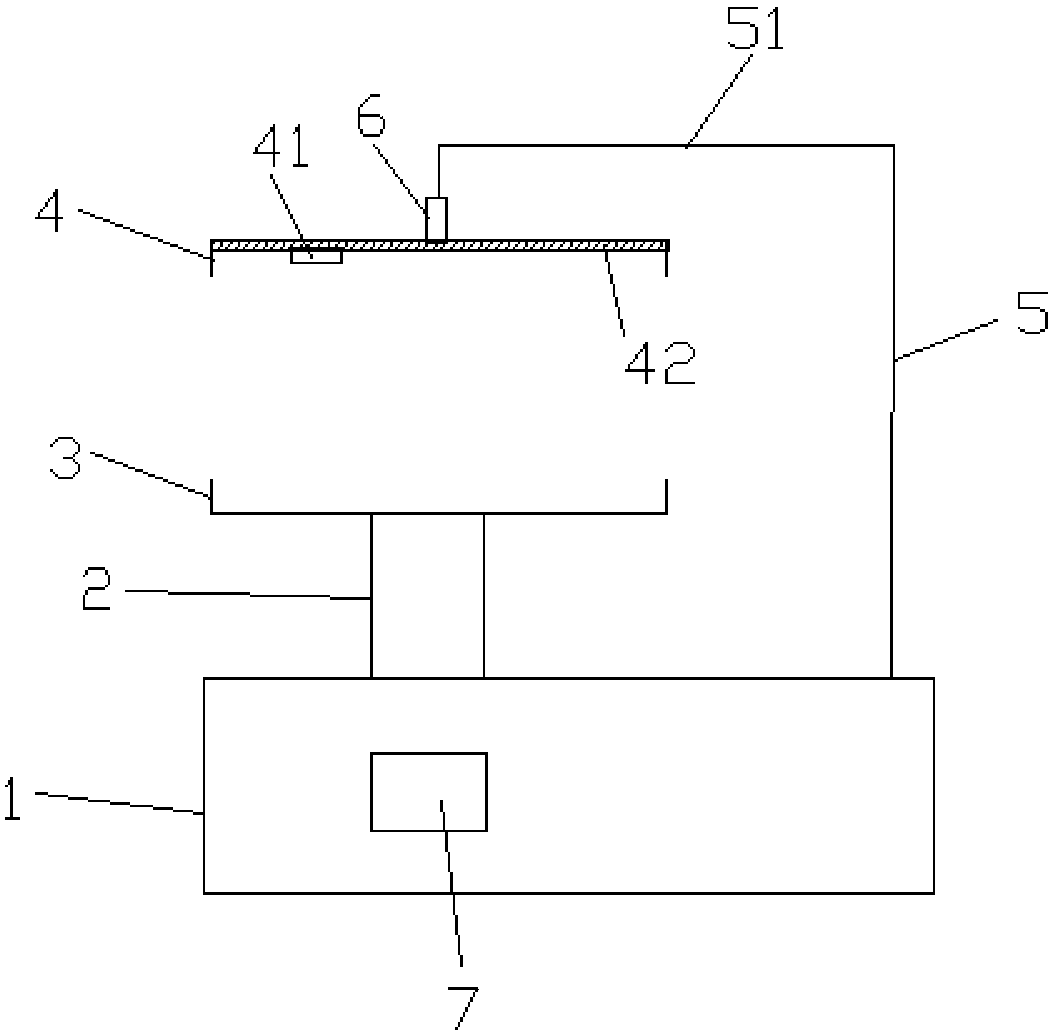

Fibre reinforced plastic (FRP) reinforcing rectangular column with corner reinforcement and construction method thereof

InactiveCN102777051AOvercoming the problem of reinforcement effect reductionTurn up Ultimate Deformation CapabilityStrutsBuilding repairsFiberFrp reinforcement

The invention discloses a fibre reinforced plastic (FRP) reinforcing rectangular column with corner reinforcement and a construction method of the FRP reinforcing rectangular column. The FRP reinforcing rectangular column is characterized in that an FRP reinforcing layer (2) of a rectangular column (1) is provided with a prefabricated chamfer (3) and corner reinforcement (4). The FRP reinforcing rectangular column has the advantages of small amount of FRP, high reinforcing efficiency, low reinforcing cost, high bearing capacity and ductility of the reinforcing column, high accuracy of FRP reinforcing construction, convenience in construction, etc.

Owner:HUNAN UNIV

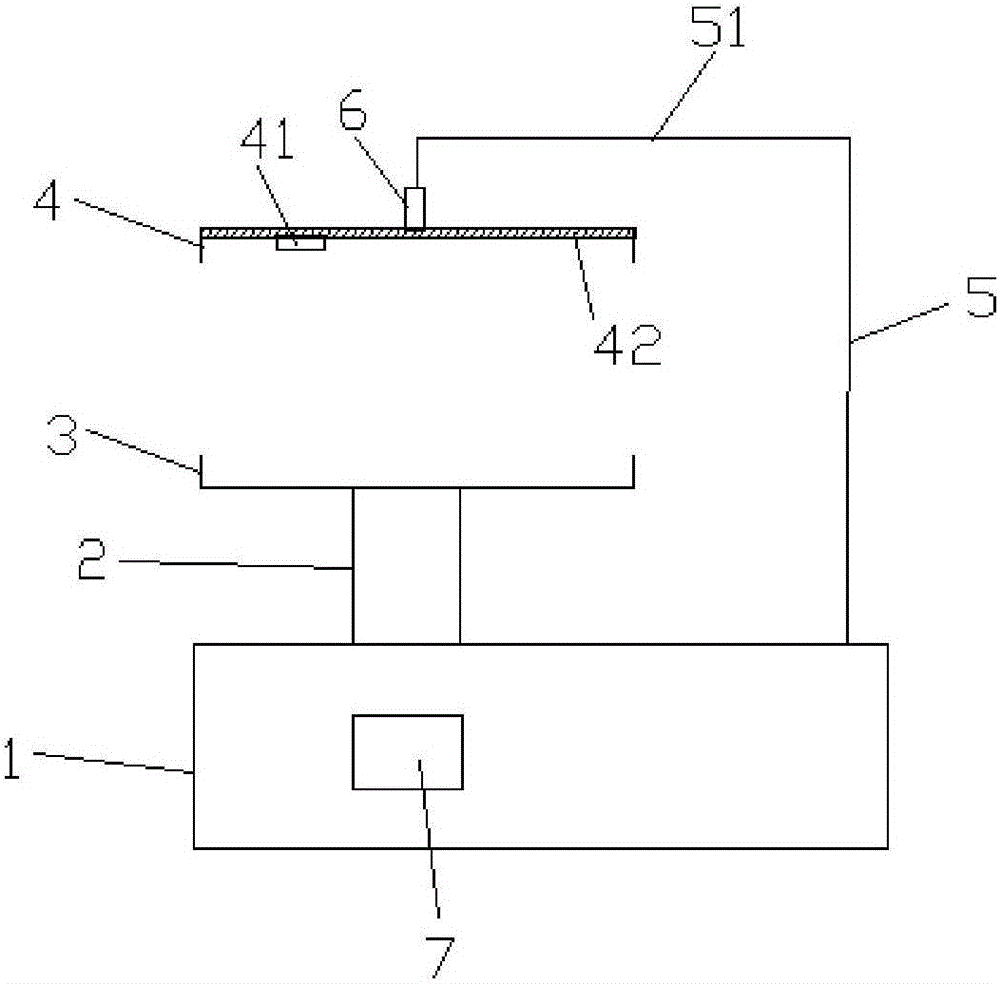

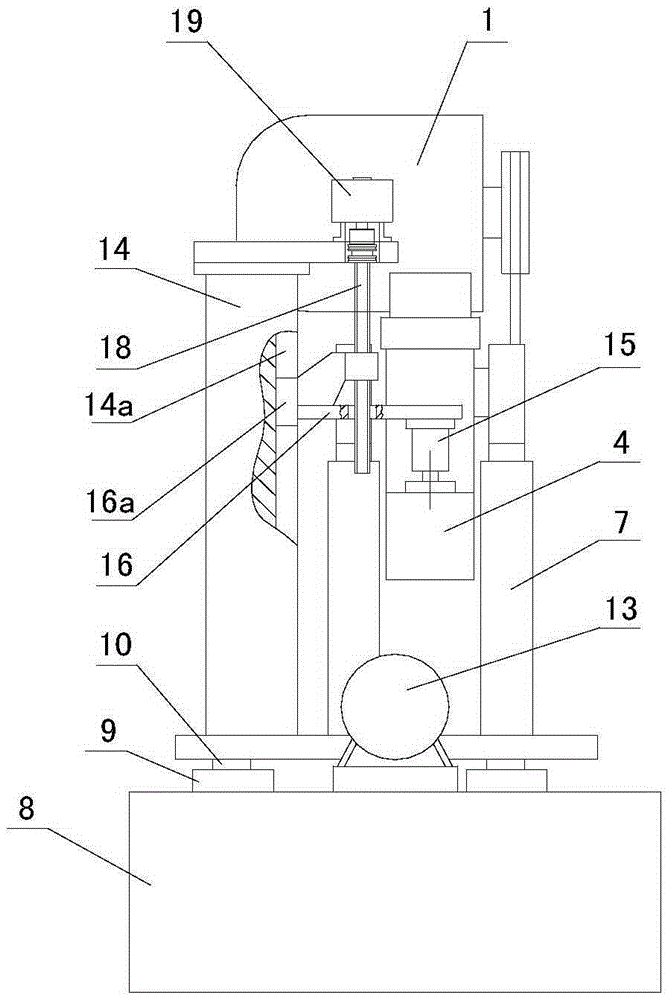

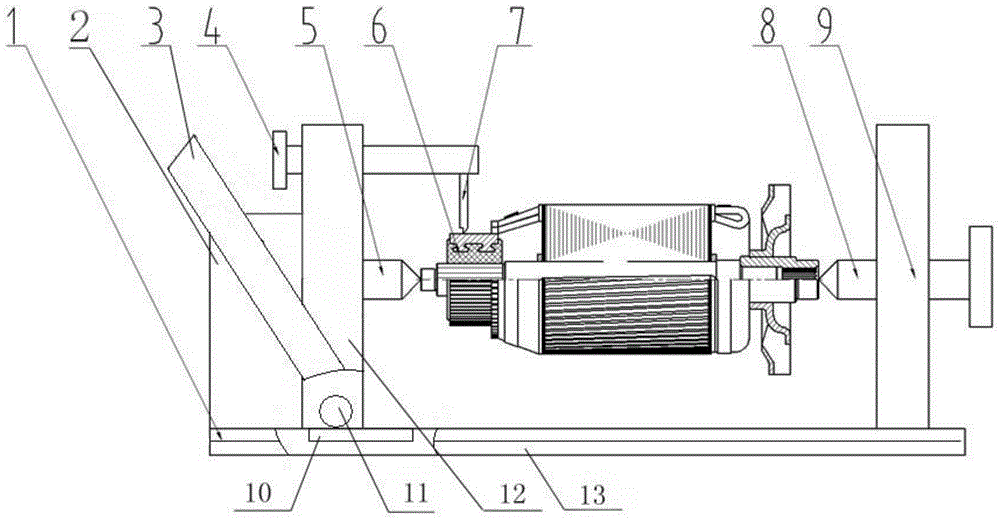

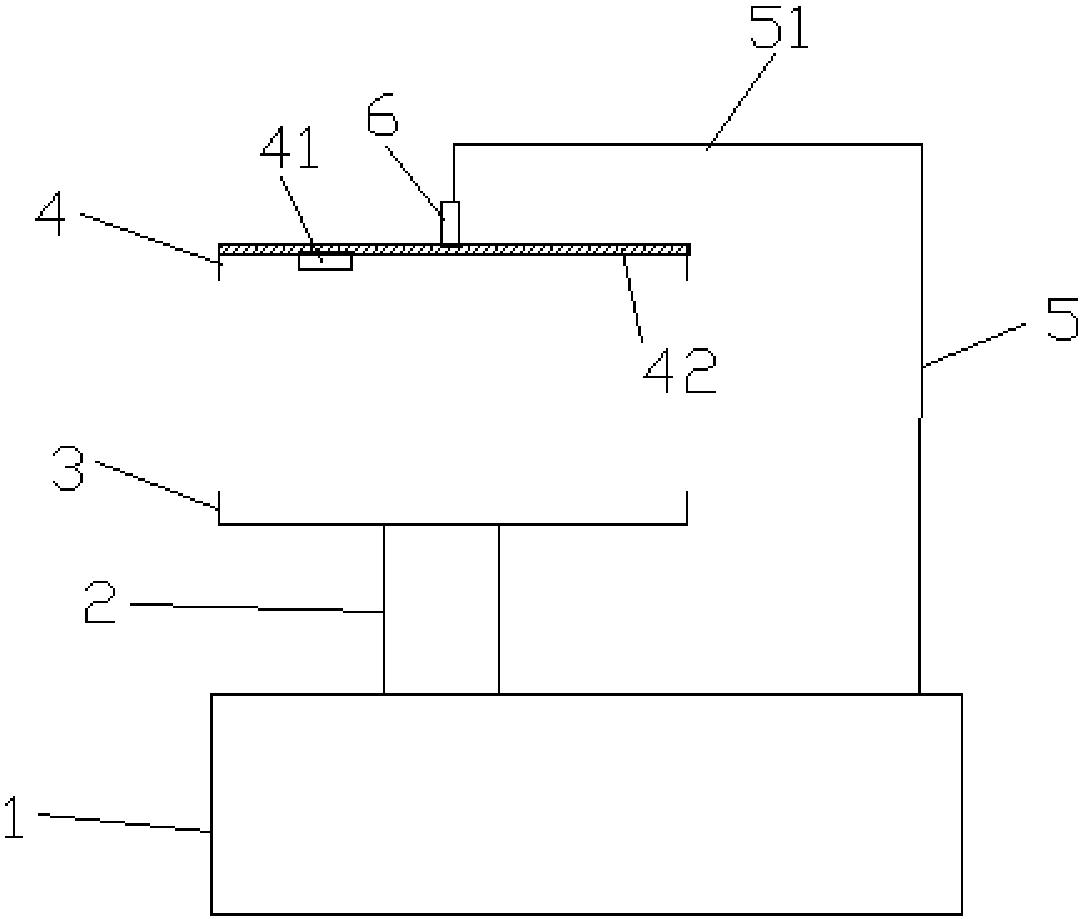

Machining device for end opening of PVC pipe

InactiveCN105382652ATimely collectionEasy to collectEdge grinding machinesGrinding drivesEngineeringGrinding wheel

The invention discloses a machining device for an end opening of a PVC pipe. The machining device comprises a first drive unit, a second drive unit, a rotating shaft, a conical grinding wheel and a clamping mechanism. The pipe to be machined is placed in grooves of a supporting plate. A first lifting unit and a power unit are used for adjusting the position of the supporting plate so that the axis of the pipeline can coincide with the axis of the grinding wheel. The first drive unit is used for driving the rotating shaft to rotate, and the second drive unit is used for driving the rotating shaft to move in the direction of the pipe. The grinding wheel is used for chamfering the end opening of the pipe. Thus, the pipe can be conveniently connected with other pipes, and installation quality is ensured. A material collecting mechanism can be used for collecting machined pipelines in time, machining work can be continuously conducted conveniently, and production efficiency is improved. The machining device is good in machining effect, high in efficiency, simple in structure and convenient to use.

Owner:安徽宁国市高新管业有限公司

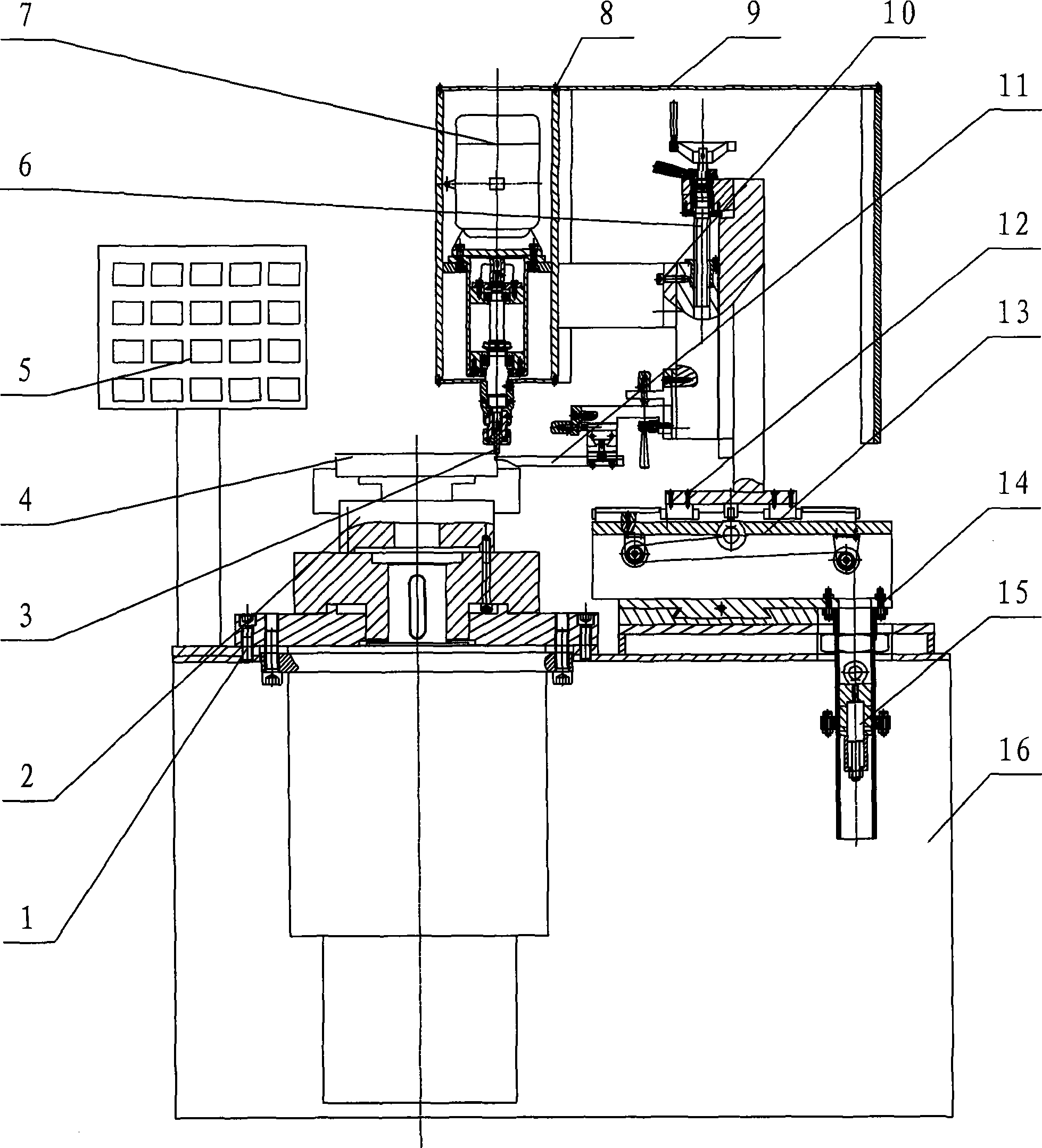

Swing regulation mechanism of gear end surface profiling chamfering machine

InactiveCN101704139AIncrease speedIncrease productivityLarge fixed membersGear-cutting machinesGear wheelEngineering

The invention relates to a swing regulation mechanism of a gear end surface profiling chamfering machine, comprising upper fixing plates and lower fixing plates according to the technical scheme, wherein the upper fixing plates and the lower fixing plates are arranged at intervals, a pin shaft is arranged between the upper fixing plate and the lower fixing plate, a connecting bar is arranged on the pin shaft by a rotating and erecting way, a power head fixing seat is fixedly arranged on the connecting bar, a profiling contact head is also arranged on the power head fixing seat, and a connecting rod swing resetting device is also arranged at one side of the power head fixing seat. The invention has simple structure, convenient installation, good operation reliability and convenient and reliable regulation, and can precisely control the chamfering size, achieve full-tooth even chamfering along the tooth height direction and reach high chamfering quality. The invention adopts a flexible joint design, and can greatly reduce the rigid impact and improve the production efficiency of a tooth-end chamfered edge by increasing the rotating speed of a workpiece.

Owner:江苏南方机电股份有限公司

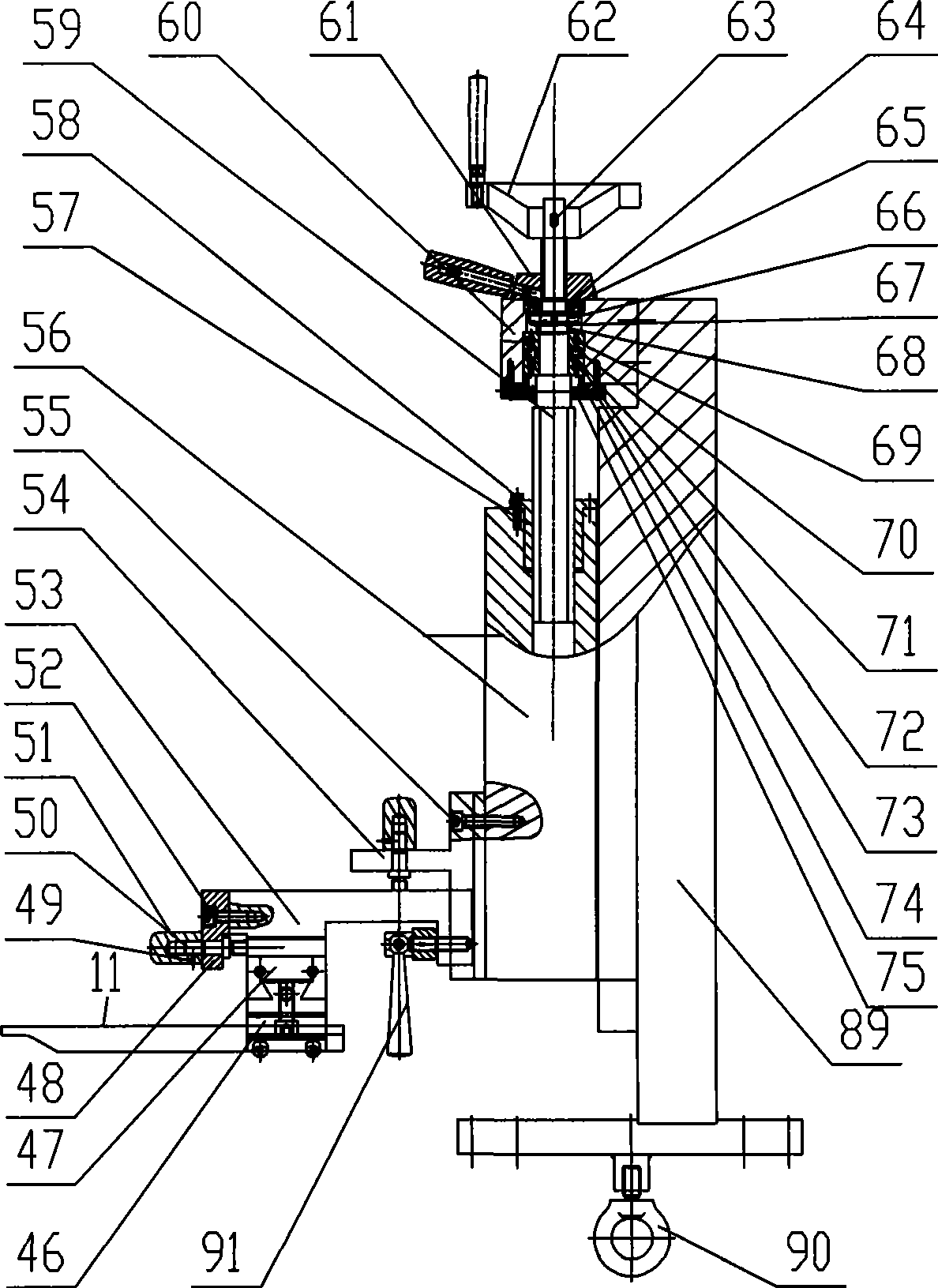

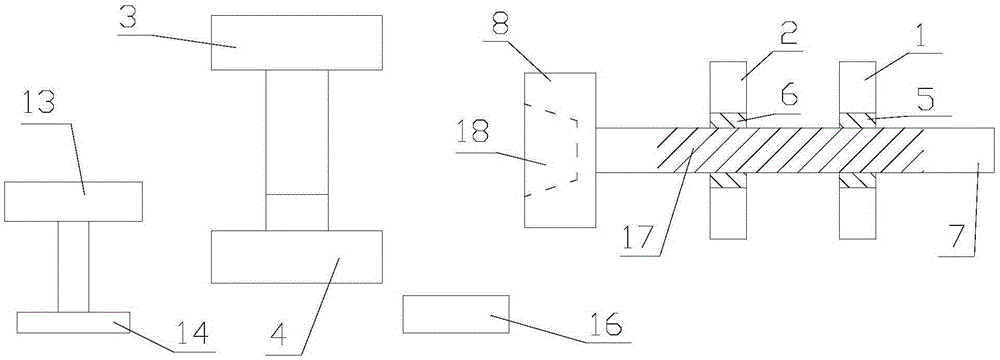

Automatic tracking type flexible grinding wheel chamfering machine

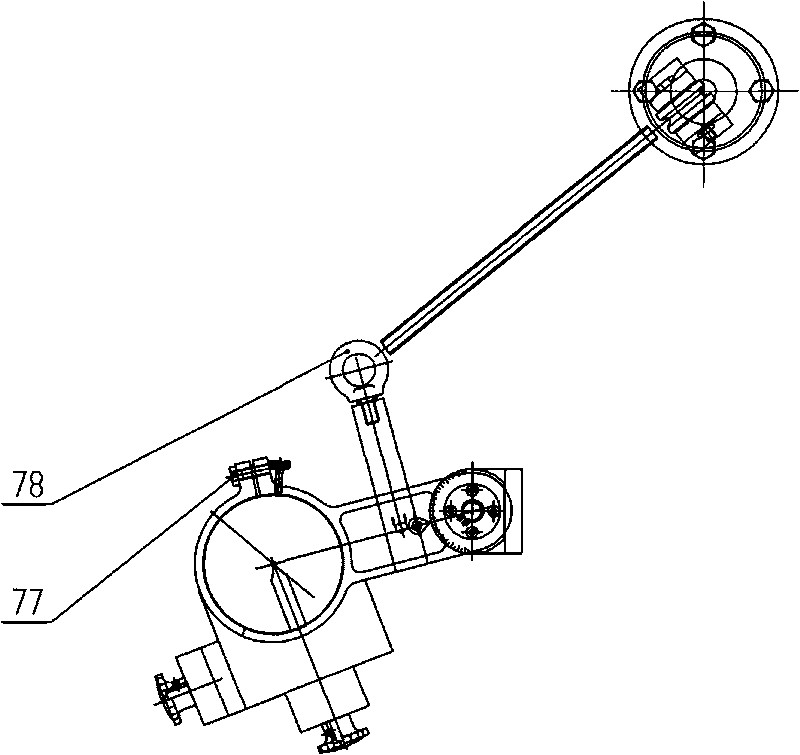

ActiveCN105364659AImprove flexibilityUniform chamferEdge grinding machinesGrinding carriagesShape changeControl system

The invention discloses an automatic tracking type flexible grinding wheel chamfering machine. The machine has a frame, a driving motor and a grinding wheel, wherein the middle part of a swing arm is hinged with the frame; the driving motor is mounted on the swing arm; a grinding wheel is mounted at one end of the swing arm; a height control mechanism is arranged above the other end of the swing arm; a moving end at the lower part of the height control mechanism is connected with a pressure applying device; and a pressure applying end of the pressure applying device is butted against the upper side of the other end of the swing arm. When the grinding wheel chamfering machine chamfers a rod, the pressure applying device is connected with a pressure control system, and the driving motor drives the grinding wheel to rotate; after a positioning device adjusts the rod to a proper height according to the diameter size of the rod, the height control mechanism and the pressure applying device are butted against one end of the swing arm, the grinding wheel at the other end of the swing arm rotates by leaning against the corner of the rod, and the grinding wheel keeps a constant grinding pressure for the end part of the rod under the effect of the pressure applying device, so that the grinding wheel can be leaned along with the end profile shape change of the rod to realize the purpose of flexible and uniform chamfering.

Owner:浩中机械(蚌埠)有限公司

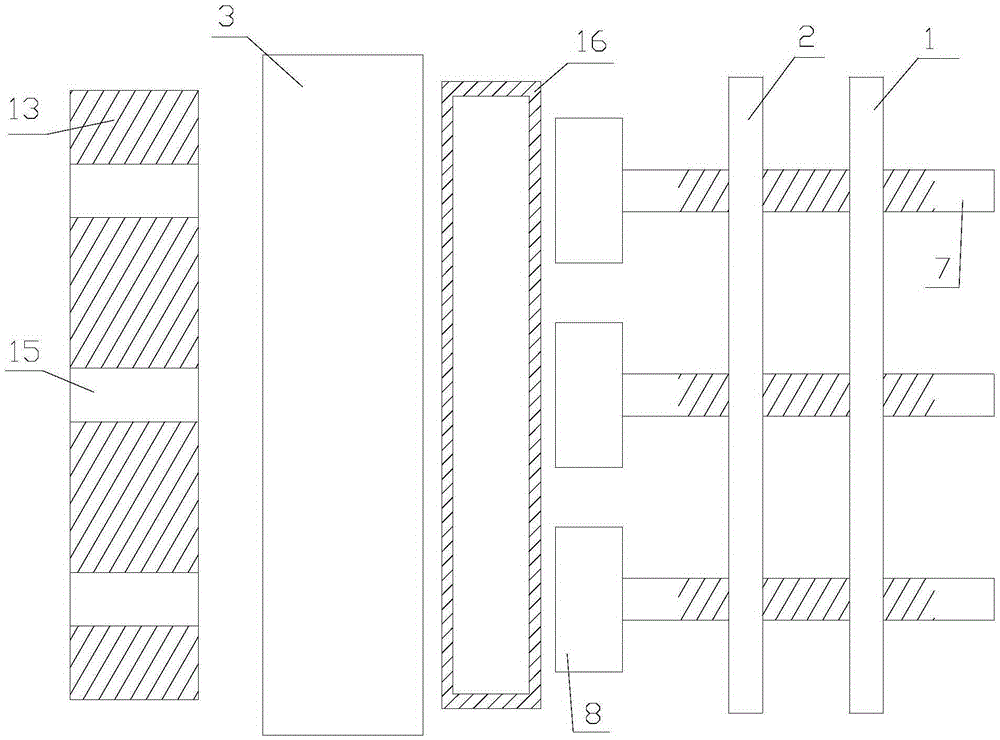

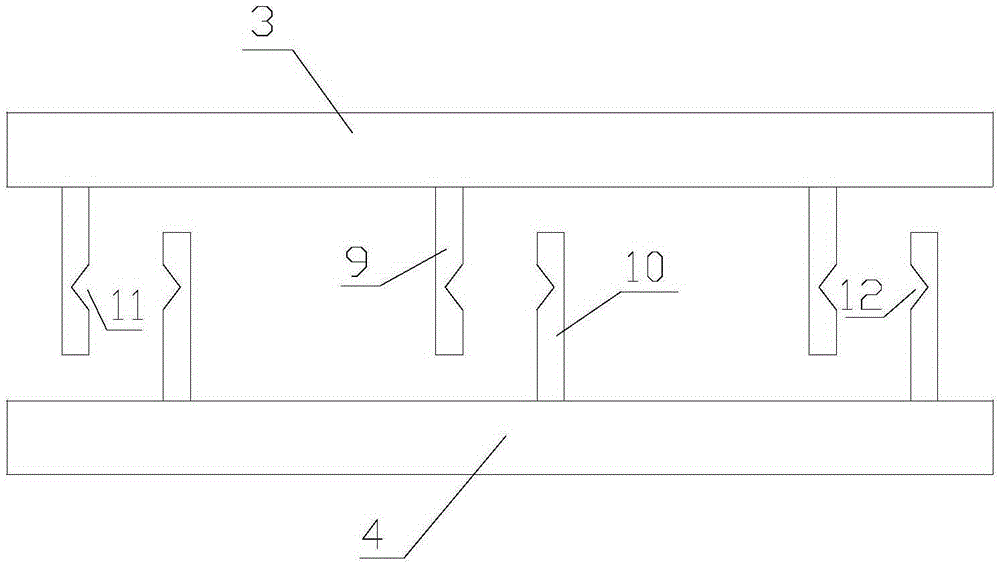

Device for carrying out external chamfering machining on end openings of plastic pipes

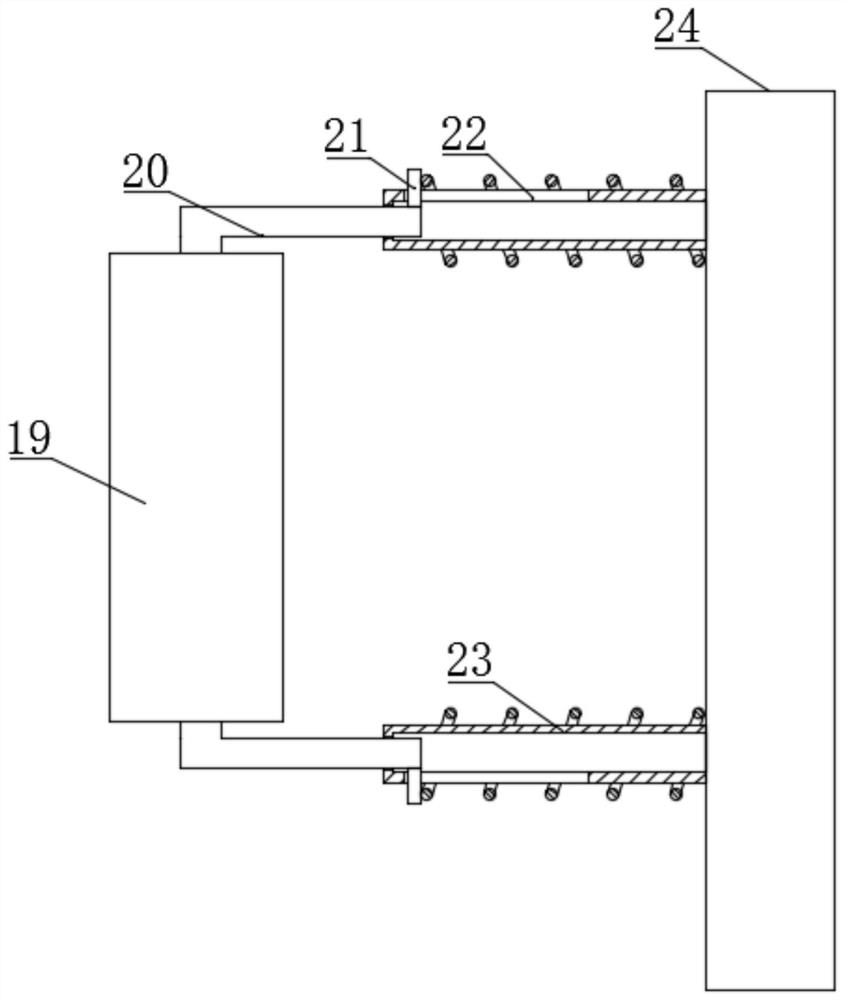

The invention discloses a device for carrying out external chamfering machining on end openings of plastic pipes. The device comprises a first installation plate, a second installation plate, N chamfering units, a driving unit, N clamping units, a first connector, a second connector, a first power unit and a second power unit. According to the device, the first power unit, the second power unit, a first clamping plate and a second clamping plate are used for clamping the pipes to be machined. The driving unit is used for driving the first installation plate to move along the axis of a rotary shaft. The rotary shaft and a grinding wheel are driven to rotate through a first inner thread, a second inner thread and an outer thread. As the second installation plate does not move, the rotary shaft also moves along the axis of the rotary shaft while rotating. In this way, a countersink in the grinding wheel can be used for carrying out chamfering machining on the outsides of the end openings of the pipes, chamfering is uniform, and the effect is good. As the multiple chamfering units and the multiple clamping units are arranged, the multiple pipes can be machined every time, and the efficiency is high.

Owner:安徽宁国市高新管业有限公司

Elliptical ceramic tube chamfering device

ActiveCN106392814AUniform chamferThere will be no uneven chamfer sizeEdge grinding machinesGrinding carriagesCylinder headEngineering

The invention relates to an elliptical ceramic tube chamfering device. First guide rails, a spring and a workpiece chuck are fixed to a rack, a sliding rack is installed on the first guide rails in a sliding mode, and the other end of the spring is connected with the sliding rack; a cylinder, second guide rails and a guide wheel support are fixed to the sliding rack, an installation rack is installed on the second guide rails in a sliding mode, and a cylinder head of the cylinder is connected with the installation rack; a guide wheel is installed on the guide wheel support, a motor is fixed to the installation rack, a grinding head shaft is rotationally installed on the installation rack, and a grinding head is fixed to one end of the grinding head shaft which is driven by the motor. According to the elliptical ceramic tube chamfering device, the sliding rack can move at will and is not affected by shapes of products, chamfers are uniform, and the phenomenon that the chamfers are unequal in size cannot occur; the chamfers with different angles can be obtained by changing angles of the grinding head, and the elliptical ceramic tube chamfering device is simple in structure and convenient to maintain and clean.

Owner:无锡康伟工程陶瓷有限公司

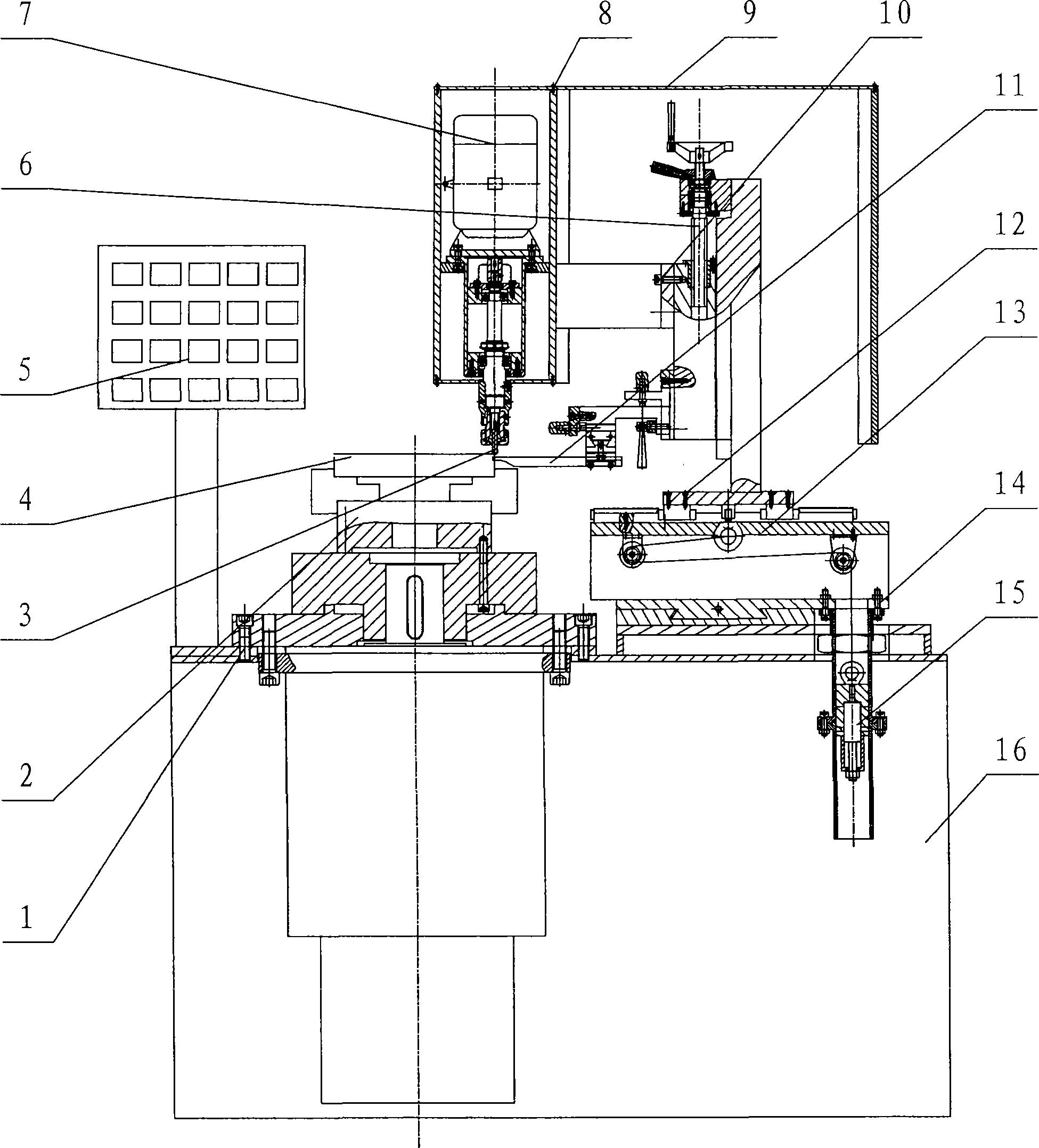

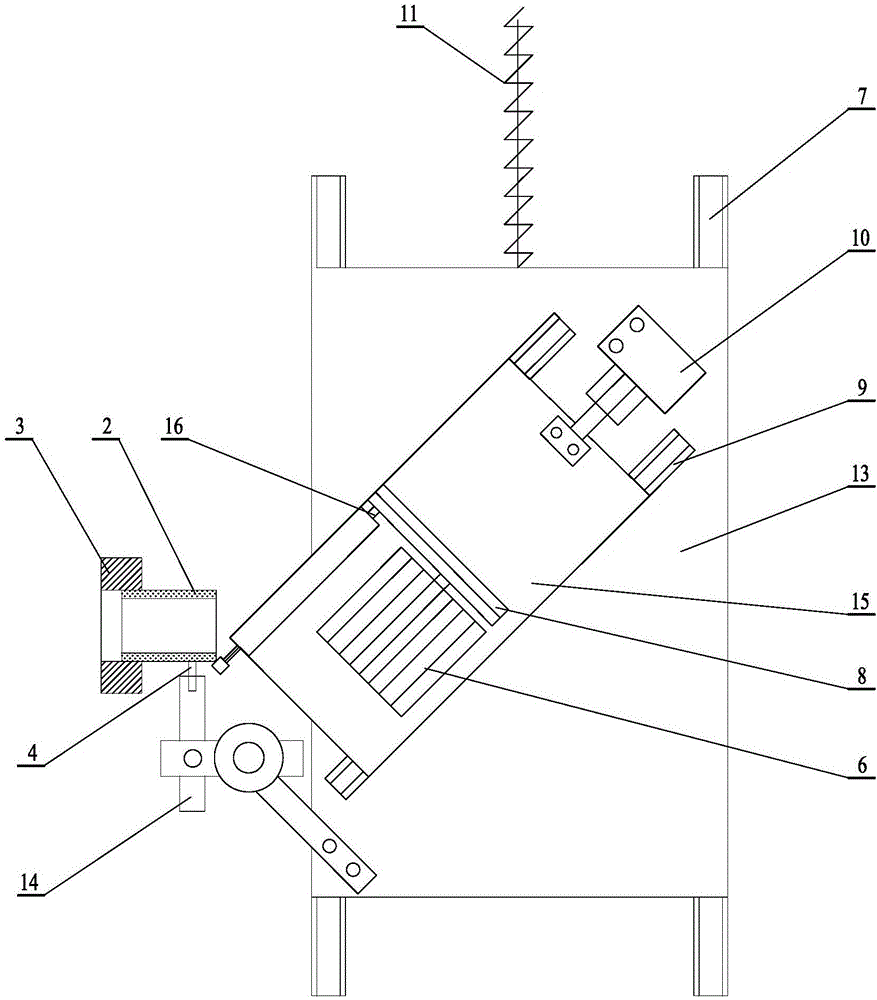

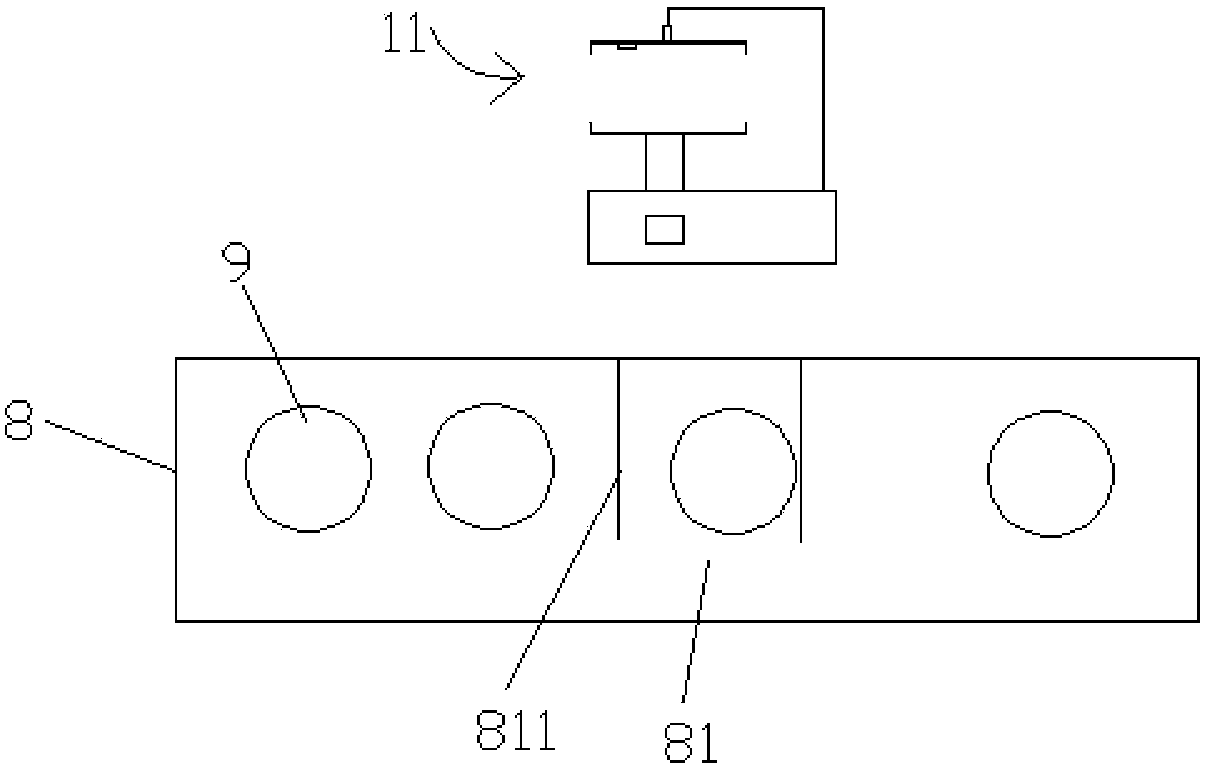

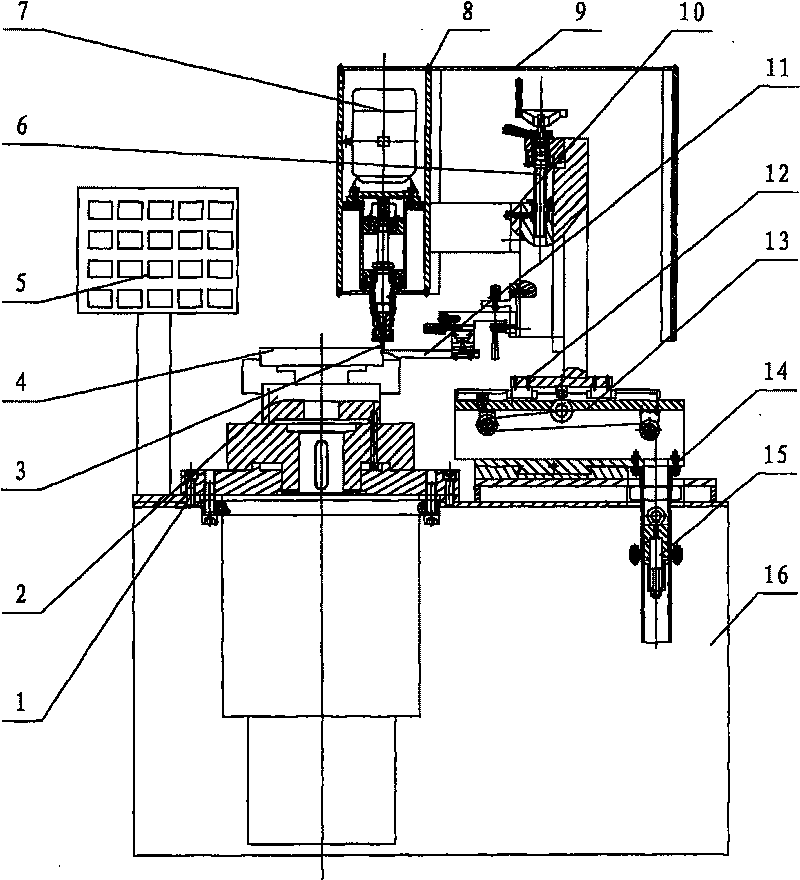

High-voltage ceramic capacitor ceramic dielectric chip on-line appearance detection and chamfering device

ActiveCN106024429AHigh degree of automationIncrease productivityFixed capacitor dielectricCapacitor manufactureDielectricAutomatic transmission

The invention discloses a high-voltage ceramic capacitor ceramic dielectric chip on-line appearance detection and chamfering device which comprises an automatic transmission line, an appearance detection device, a deburring device, a computer and a nonconforming product box. A deburring station and an appearance detection station are arranged on the automatic transmission line. The deburring device comprises a positioning electromagnet. The appearance detection device is arranged on the automatic transmission line upstream or downstream the deburring device. The appearance detection device comprises vertical and horizontal probes. Vertical and horizontal probes are connected with the computer. The vertical probe is located right above a ceramic dielectric chip on the automatic transmission line. Through the structure, the on-line appearance detection and chamfering device can automatically detect the appearance of the ceramic dielectric chip, and has the advantages of automatic and online deburring, uniform chamfering, high automation degree, low labor intensity and high production efficiency.

Owner:SUZHOU HONGQUAN HIGH VOLTAGE CAPACITOR

Traction motor rotor commutator chamfering machine

InactiveCN104966974ASimple structureChamfer straightness is stableCommutators manufactureMechanical engineeringCommutator

The invention relates to the field of metal processing, and particularly relates to a traction motor rotor commutator chamfering machine, which comprises a front support and a rear support arranged at two ends of a bottom support. The front support is provided with a center, the rear support is provided with a mobile center, a tool carrier is arranged between the front support and the rear support, the tool carrier moves along a guide rail, a scraper is arranged on the tool carrier, and the scraper is provided with two blades. According to the traction motor rotor commutator chamfering machine, the structure is simple, two centers are adopted for positioning, the two centers are ensured to be in the same axial direction, a precious guide rail is used for driving the tool carrier to move, chamfering straightness is ensured to be stable, chamfering is ensured to be uniform, chamfering is carried out on commutating segments at two sides at one time in the case of processing, and the processing efficiency is high.

Owner:ZIBO SUPER MOTOR

Stainless steel harness wire cleaning and grinding device

InactiveCN102229095AQuality improvementExtended service lifeEdge grinding machinesPolishing machinesHoneycombMechanical engineering

The invention discloses a stainless steel harness wire cleaning and grinding device. The grinding device comprises a harness wire grinding barrel, wherein the grinding barrel is formed by mounting a plurality of small grinding inner cylinders in a large grinding outer cylinder; the small grinding inner cylinders are uniformly arranged in the grinding outer cylinder and have equal internal diameter; the grinding outer cylinder is a hexagonal empty barrel; and the small grinding inner cylinders are hexagonal empty barrels and are uniformly arranged in the grinding outer cylinder in a honeycomb shape. Through the device, the cleaning and the grinding of stainless steel harness wires can be realized in a large scale, the yield is greatly increased, and the energy consumption is obviously reduced. The produced harness wire has stable quality, long service life and a flat and smooth surface, and the punched edge is smooth and burr-free, so that the harness wire can freely slide.

Owner:林佳贤

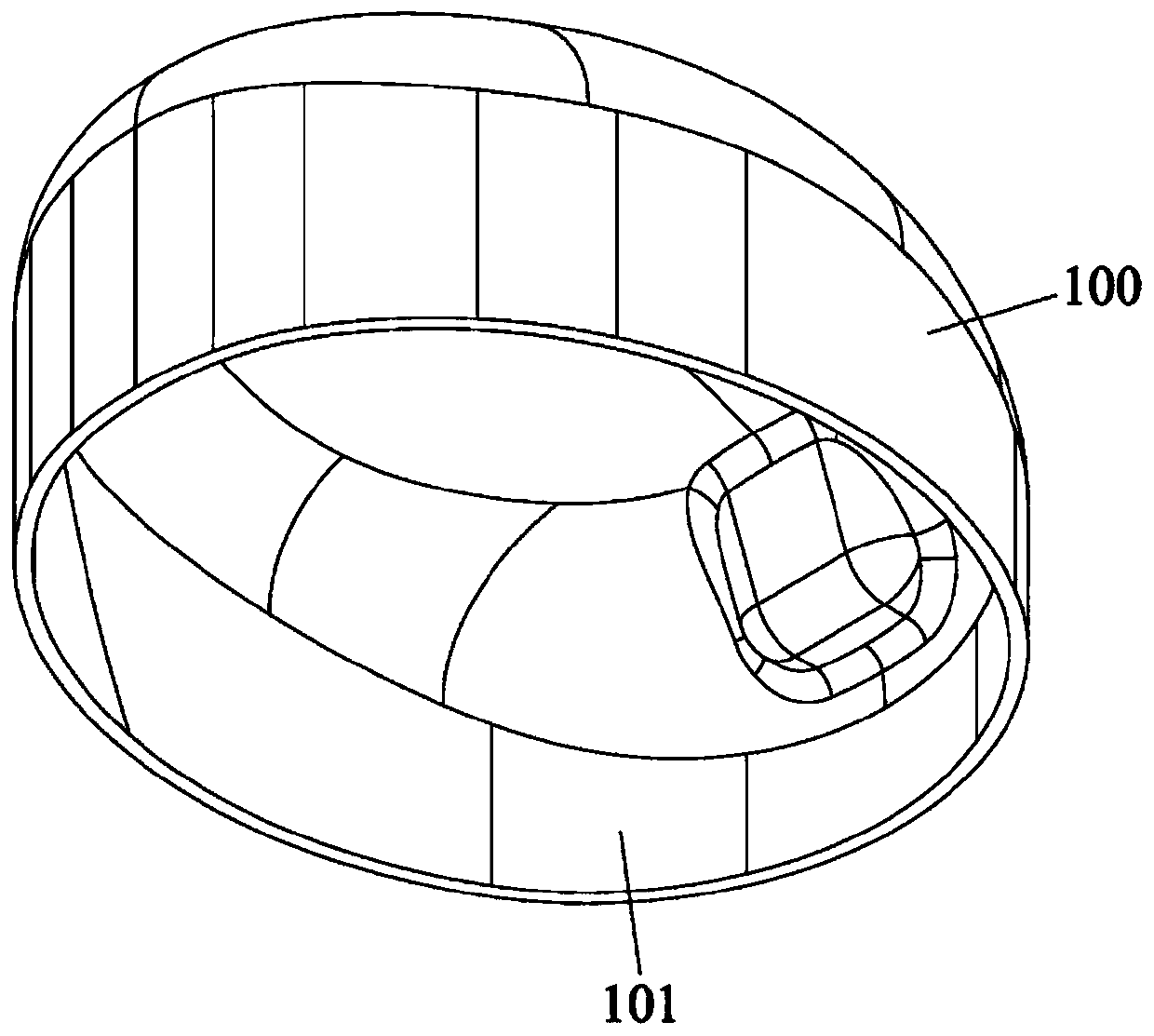

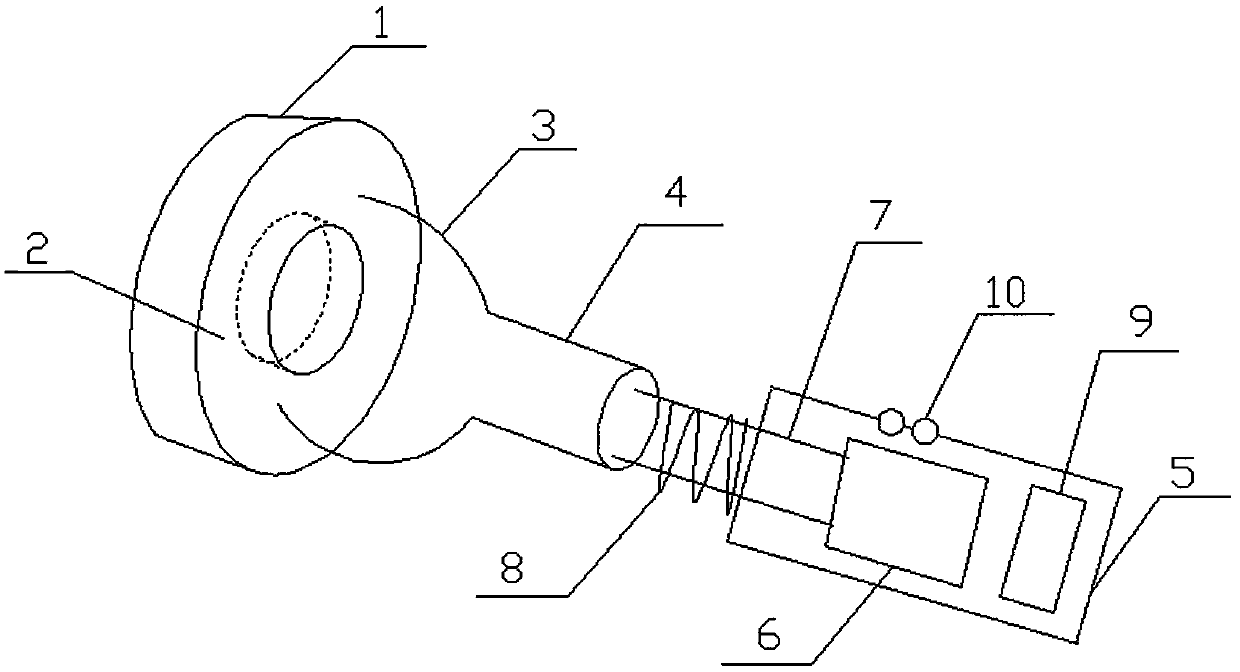

Manual chamfering device of magnetic ring

InactiveCN103737448AUniform chamferChamfer without omissionEdge grinding machinesInductances/transformers/magnets manufactureKey pressingEngineering

The invention discloses a manual chamfering device of a magnetic ring. The manual chamfering device of the magnetic ring comprises a ring provided with a groove in the middle, and a handle internally provided with a motor. The groove is matched with the annular end face of the magnetic ring to be chamfered, and a chamfer polishing mechanism is arranged at the bottom of the groove. The bottom, away from the side of the groove, of the ring is fixedly provided with a hollow threaded rod provided with outer threads through a connecting piece. The motor is connected with a rotation shaft extending out of the top end of the handle, and the extending end of the rotation shaft is provided with outer threads matched with the hollow threaded rod. The handle is provided with a switch key. By means of the structure, the ring end face of the magnetic ring to be chamfered is arranged in the groove of the ring, the rotation shaft drives the ring to rotate under the drive of the motor, when the chamfer polishing mechanism in the groove rotates, an inner corner and an outer corner of the magnetic ring to be chamfered are chamfered, and therefore chamfering is even and free of leakage, and production efficiency is high.

Owner:WUJIANG ZHENYU SEWING EQUIP

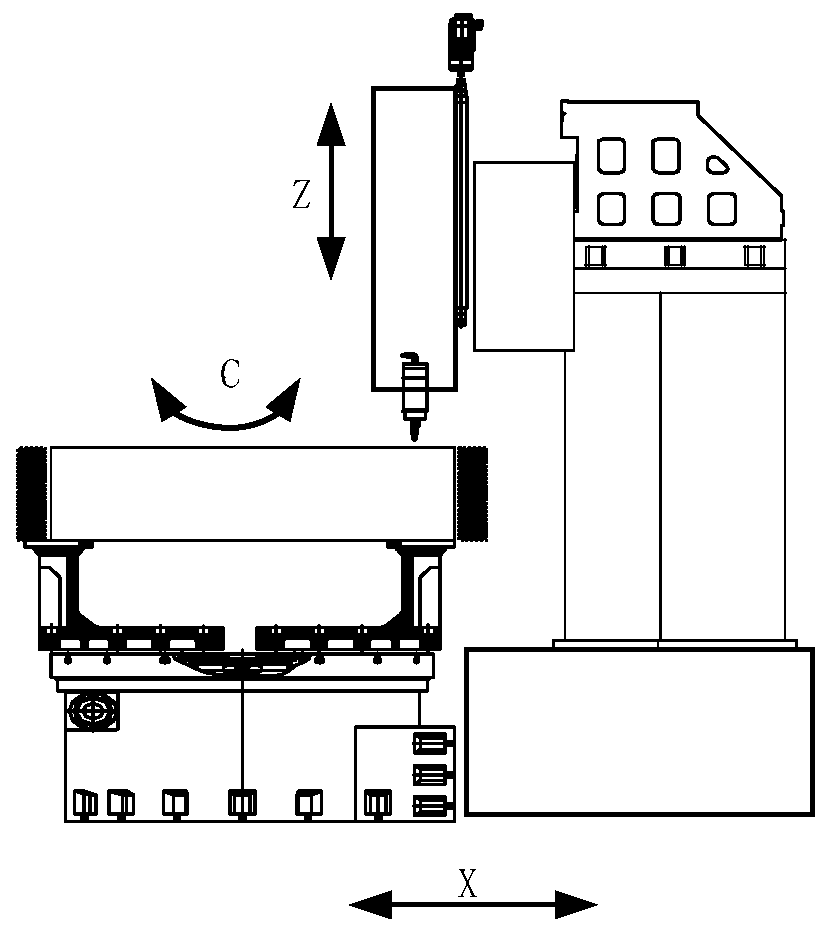

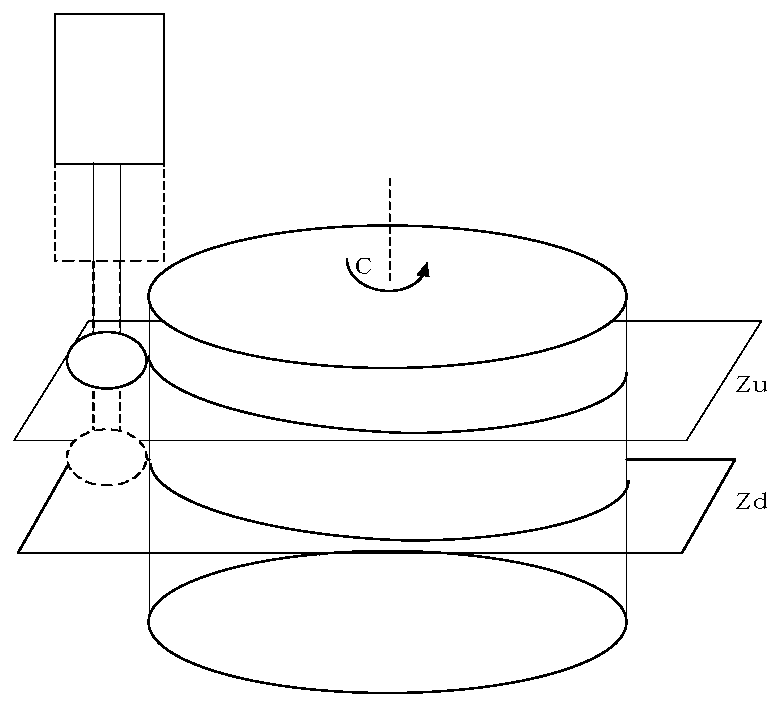

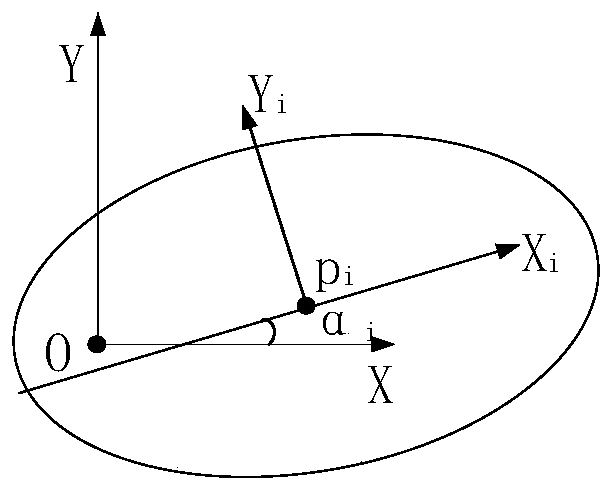

Correction-free numerical control chamfering algorithm based on polar coordinate machine tool

ActiveCN109947045AWithout adding complexityUniform chamferNumerical controlNumerical controlComputer science

The invention relates to the technical field of numerical control machinery, in particular to a correction-free numerical control chamfering algorithm based on a polar coordinate machine tool. On thebasis of a machining principle of the polar coordinate machine tool which only has an X axis, a Z axis and a C axis, a cylindrical gear is free of correction, eccentric deflection is detected automatically, under the state, a deflection axis does not need to be added, and space chamfering is realized by a cone curve on a cone cutter. According to the method, any two measurable planes in the axialdirection are selected, points are respectively collected according to an equal angle method, relative position models of a machining coordinate system and a workpiece coordinate system are established, a mutual conversion relation is obtained, the position of a target machining contour of the cylindrical gear in the machining coordinate system is obtained, and a cutter point is obtained accordingto the cutting characteristic of the cone curve. The chamfering processing operation process is simplified, and the processing efficiency is improved.

Owner:NANJING GONGDA CNC TECH

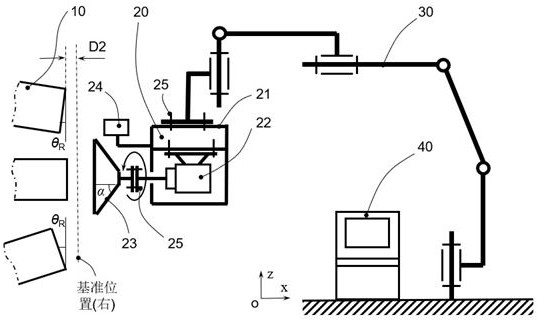

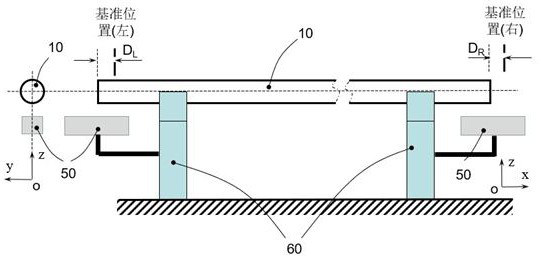

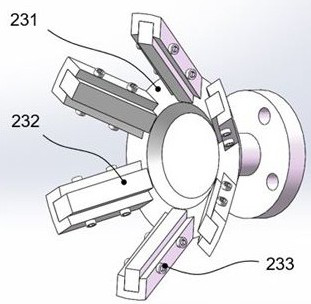

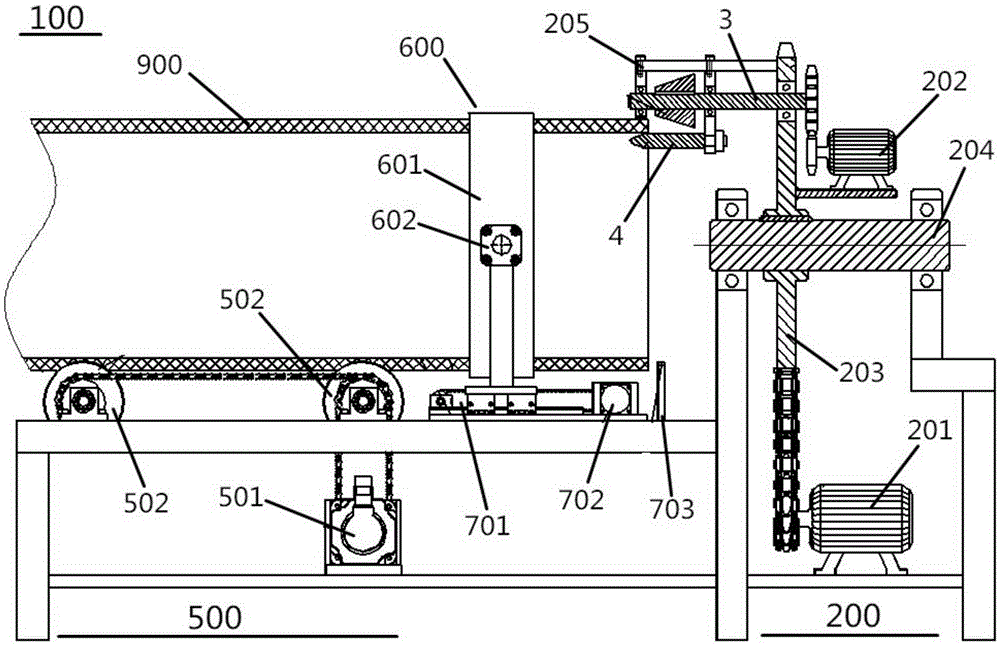

Bar chamfering robot system and method

PendingCN114310539AUniform chamferMeet chamfering requirementsEdge grinding machinesGrinding drivesRobotic systemsVertical plane

The invention relates to a bar chamfering robot system and method, chamfering is carried out in a mode that a bar is fixed and a grinding / cutting tool rotates, and the bar chamfering robot system comprises a robot body, a control system, a position sensor, a fixing frame, a driving motor, a grinding / cutting head and an industrial camera. Firstly, the position sensor obtains deviation values between the two ends of the bar and the reference position, then, the industrial camera obtains an offset angle between the end face of the bar and the vertical plane, and finally, the control system processes the data and controls the posture and the movement distance of the end executor, so that the purpose of bar end face chamfering is achieved. According to the invention, the two end surfaces of the bar can be synchronously and uniformly chamfered in a full circumference manner, the dependence on the bending degree and the end surface cutting inclination of the supplied bar is reduced, and the same set of grinding / cutting head can realize the chamfering operation of the bars with different diameters and the same angle, so that the time and the labor are saved, and the working efficiency and the chamfering quality are improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

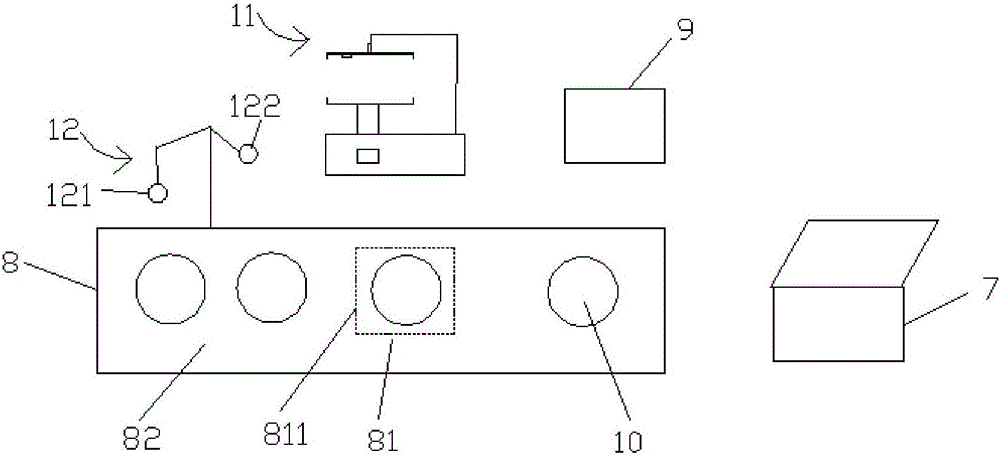

An online deburring machine based on high-voltage ceramic capacitor ceramic dielectric chip

ActiveCN106002528BUniform chamferIncrease productivityEdge grinding machinesCapacitor manufactureDielectricAutomatic transmission

The invention discloses an online burr remover based on a ceramic medium chip of a high-pressure ceramic capacitor. The online burr remover comprises an automatic transmission line and a burr removing device. A burr removing station is arranged on the automatic transmission line, and includes two separation plates; each separation plate can be opened and closed; a gap between the two separation plates is larger than the diameter of the ceramic medium chip, but is smaller than two times of the diameter of the ceramic medium chip; and the burr removing device is arranged on one side of the burr removing station. The burr removing device includes an upper mold, a lower mold, a rotating shaft, a pressure sensor, an electromagnet, a support rod, a rotating bearing and a control panel. After the structure is adopted, and the ceramic medium chip is transmitted to the burr removing station, the electromagnet is electrified, and the ceramic medium chip positioned on the burr removing station is transferred to the lower mold of the burr removing device for removing burrs. After the burrs are removed, the electromagnet is electrified again, and the ceramic medium chip on the lower mold is automatically adsorbed and transferred onto the automatic transmission line again.

Owner:链芯科技有限公司

Chamfering device of thin wall cylinder part

PendingCN107584176AImprove roundnessUniform chamferPositioning apparatusMetal-working holdersThin walledEngineering

The embodiment of the invention discloses a chamfering device of a thin wall cylinder part. The chamfering device comprises a cutter, a cutter fixing base, a workpiece positioning body and a spindle,the cutter is fixedly mounted on the cutter fixing base, and the cutter fixing base is mounted on the spindle; the cutter is driven by the cutter fixing base to rotate around the axis of the spindle,the workpiece positioning part is arranged on the spindle in a sliding and sleeving mode, the outer wall of the workpiece positioning part is tightly attached to the inner wall of the thin wall cylinder part, and the workpiece positioning part and the thin wall cylinder part together slide relative to the spindle and move close to the rotating cutter to conduct chamfering. The chamfering device ofthe thin wall cylinder part is simple and reliable in structure, workpieces easily enter the device and break away from the device, a special chamfering cutter is not needed to be used for the cutter, the chamfering quality is good, the efficiency is high, the cost is low, the workpieces after chamfering are not deformed easily, the circular degree can be guaranteed, and the chamfering device isparticularly suitable for chamfering of easily-deformed thin wall cylinder parts.

Owner:揭阳市汇宝昌电器有限公司

An integrated ceramic tile 45 degree chamfering polishing machine

ActiveCN110181356BAvoid uneven chamfersPrevent jackingEdge grinding machinesGrinding feedersPolishingElectric machinery

The invention discloses an integrated ceramic tile 45-degree chamfering polishing machine which comprises a machine body, a rectangular hollow groove, a grinding wheel and a vertical pressing device.The upper surface of the machine body is provided with the rectangular hollow groove, a left port of the rectangular hollow groove is provided with the grinding wheel, the grinding wheel is in transmission connection with a driving motor, the port of the rectangular hollow groove is provided with an L-shaped cover plate, and a vertical plate of the L-shaped cover plate is fixed on the right side wall of the machine body through a screw. In the actual use process, a ceramic tile can be placed on the upper surface of the L-shaped cover plate, then the edge of the ceramic tile is chamfered and polished through the grinding wheel by pushing the ceramic tile, and in the process that the ceramic tile is pushed from front to back, the vertical pressing device presses the ceramic tile on the uppersurface of the L-shaped cover plate, so that the edge of the ceramic tile is prevented from being jacked up by the grinding wheel, and uneven chamfering is avoided. Meanwhile, the limiting device canextrude the ceramic tile towards the direction of the grinding wheel, so that the ceramic tile is pressed on the surface of the grinding wheel, and chamfering is more uniform and stable.

Owner:临沂文衡信息技术有限公司

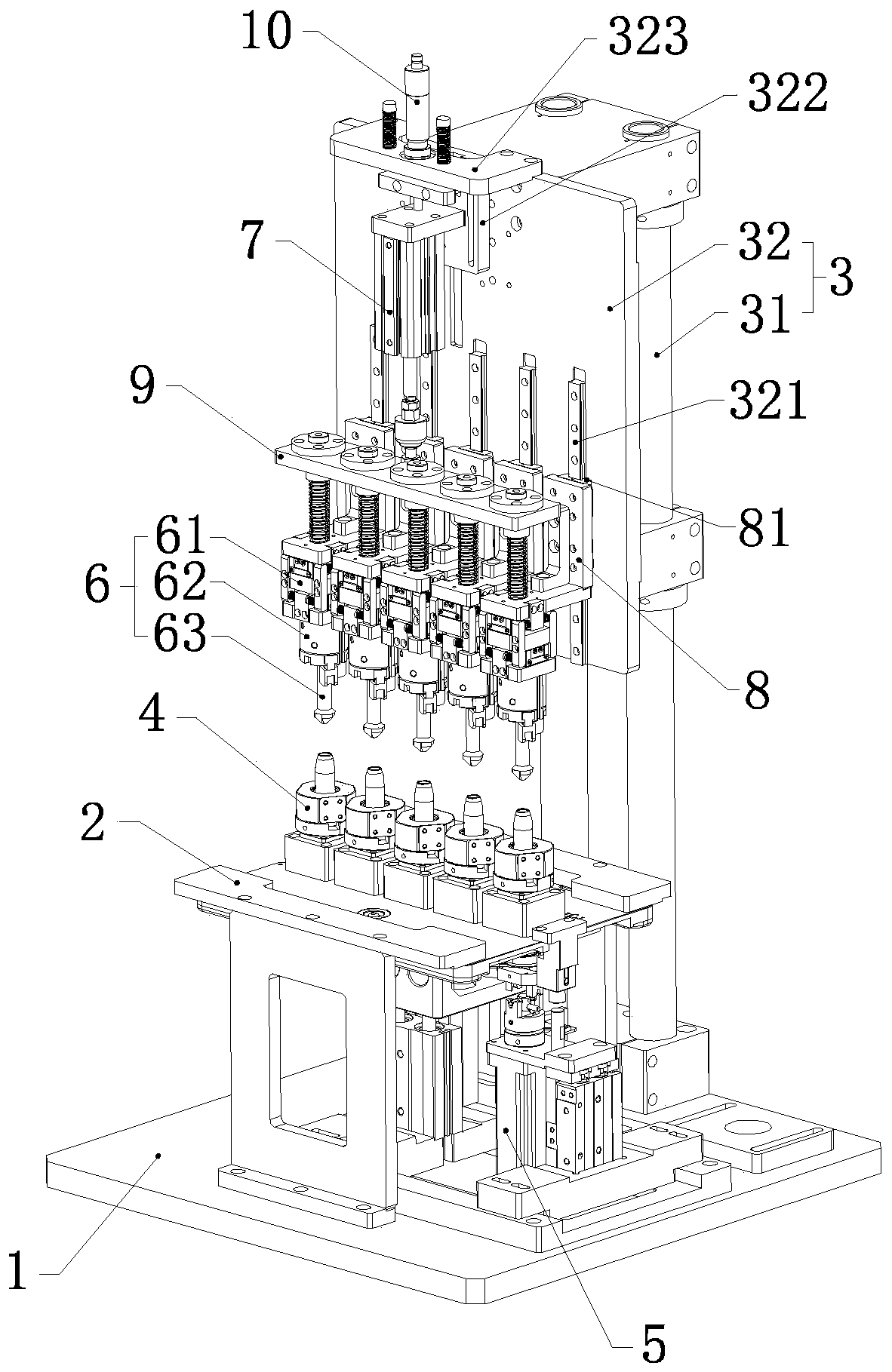

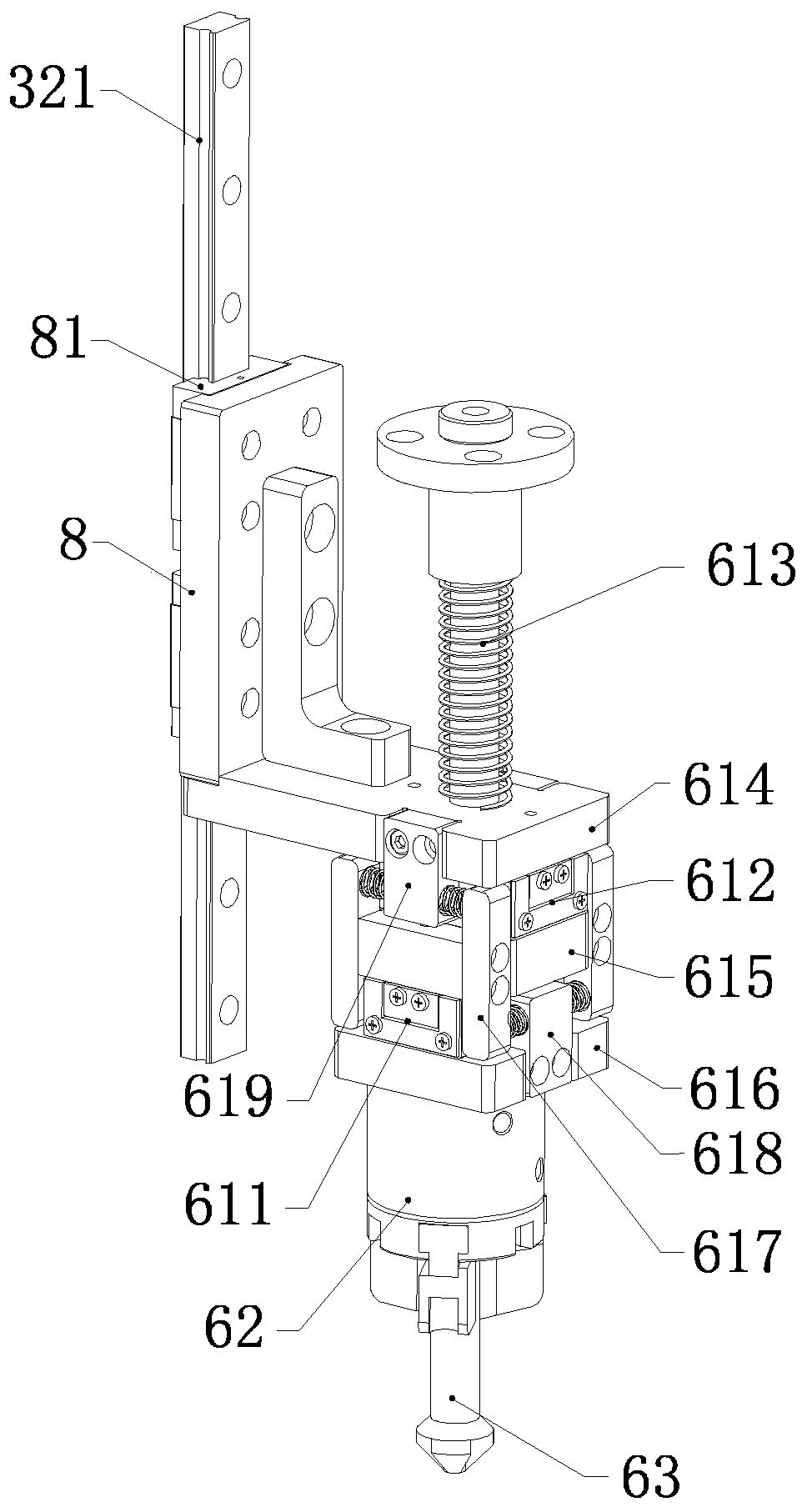

Chamfering mechanism capable of eliminating deviation

The invention provides a chamfering mechanism capable of eliminating deviation. The chamfering mechanism comprises a rack, wherein the rack comprises a base, a mounting base and a supporting assembly,wherein at least one rotary jig used for mounting a to-be-processed product is arranged on the mounting base; a first drive device for driving the rotary jig to rotate is arranged on the base; a floating tool assembly which corresponds to the rotary jig is slidably connected on the supporting assembly; a second drive device for pushing the floating tool assembly is further arranged on the supporting assembly; the floating tool assembly is provided with a floating regulating part, a clamping device and a chamfering knife; the floating regulating part is provided with an X-axis regulating assembly, a Y-axis regulating assembly and a Z-axis regulating assembly; the clamping device is mounted on the floating regulating part; and the chamfering knife is mounted in the clamping device. The chamfering mechanism can eliminate concentricity deviation and height deviation during chamfering, guarantees chamfering effect, and improves production efficiency.

Owner:XIAMEN YOUXIN INFORMATION TECH CO LTD

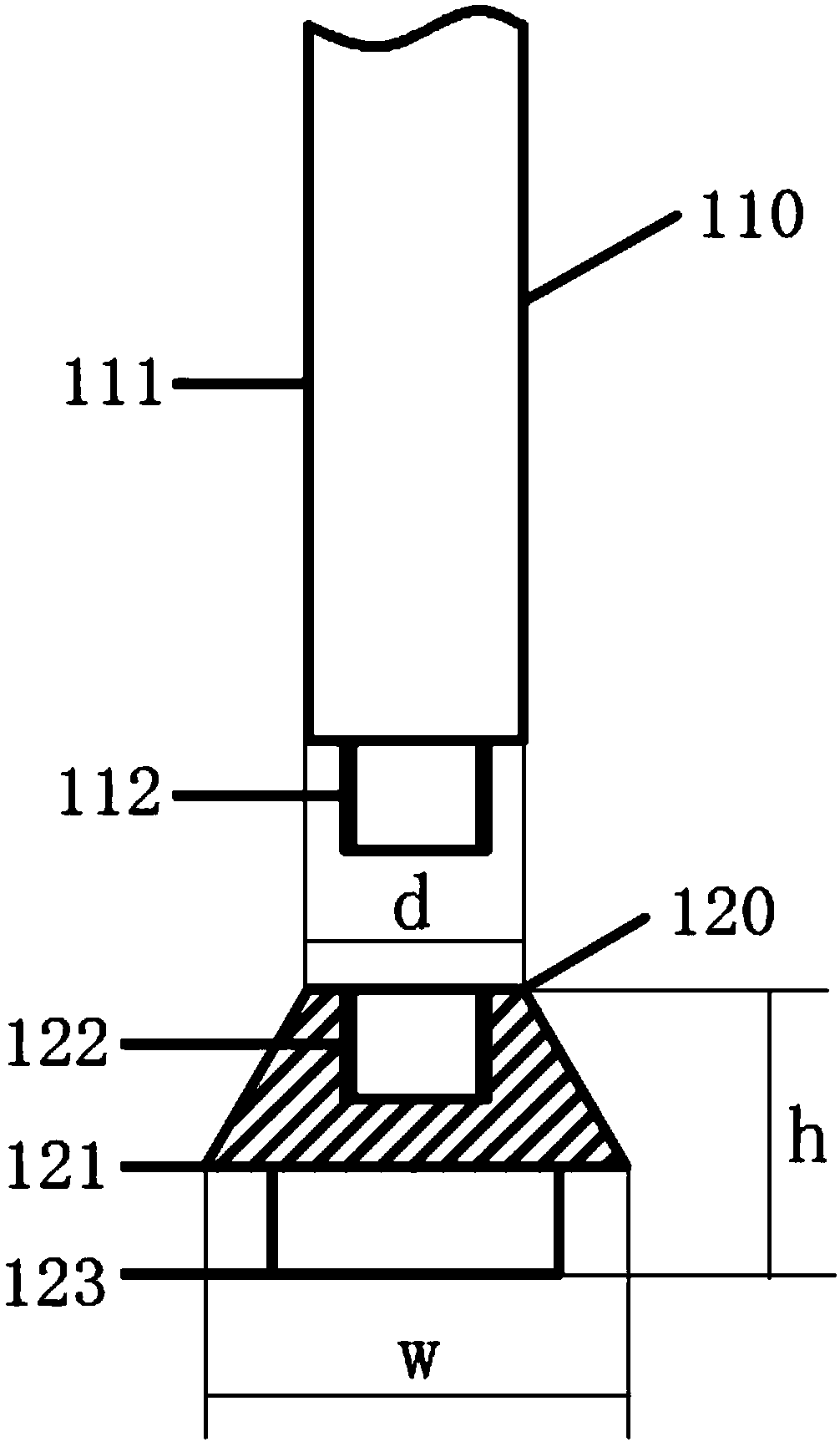

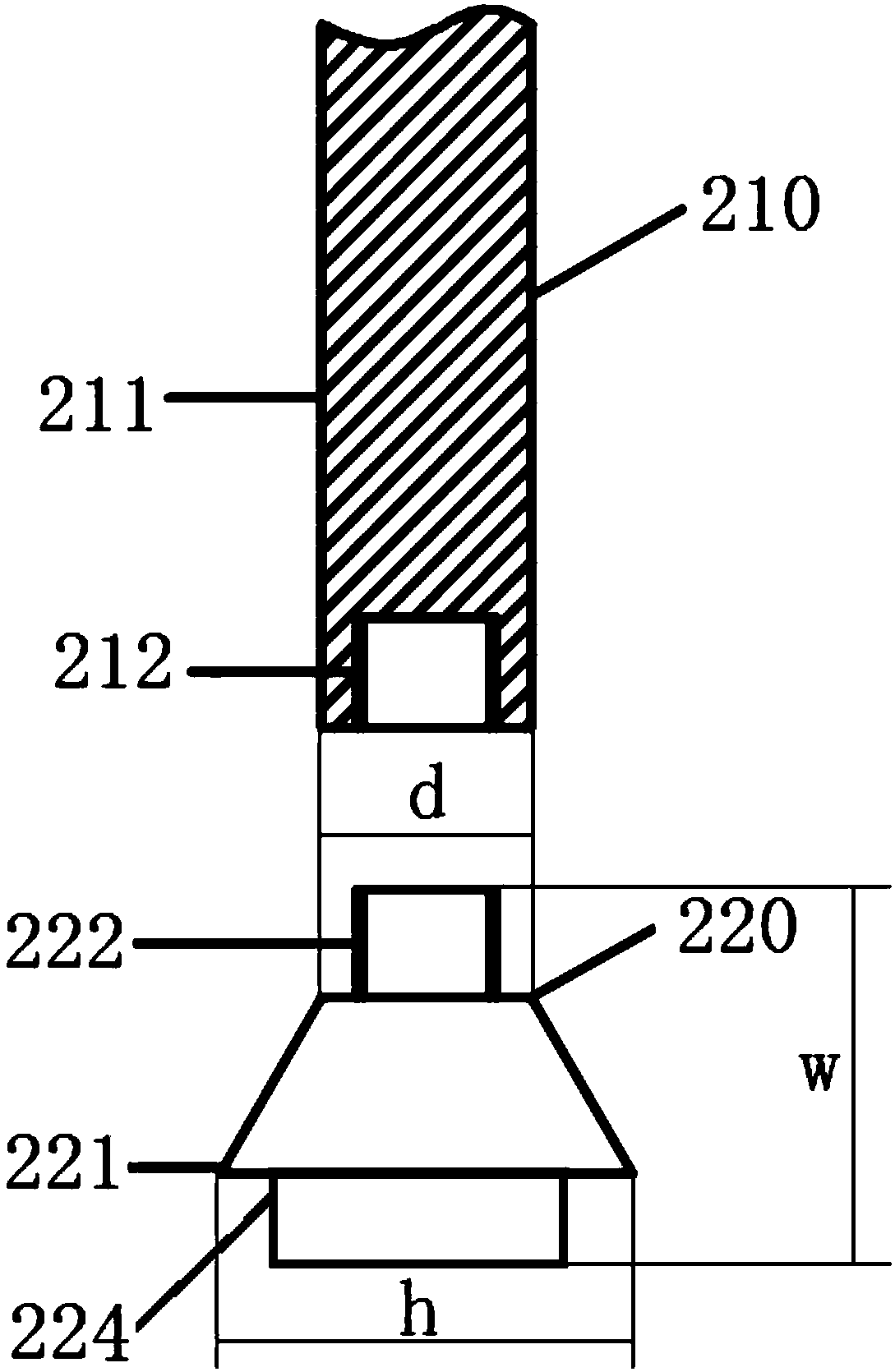

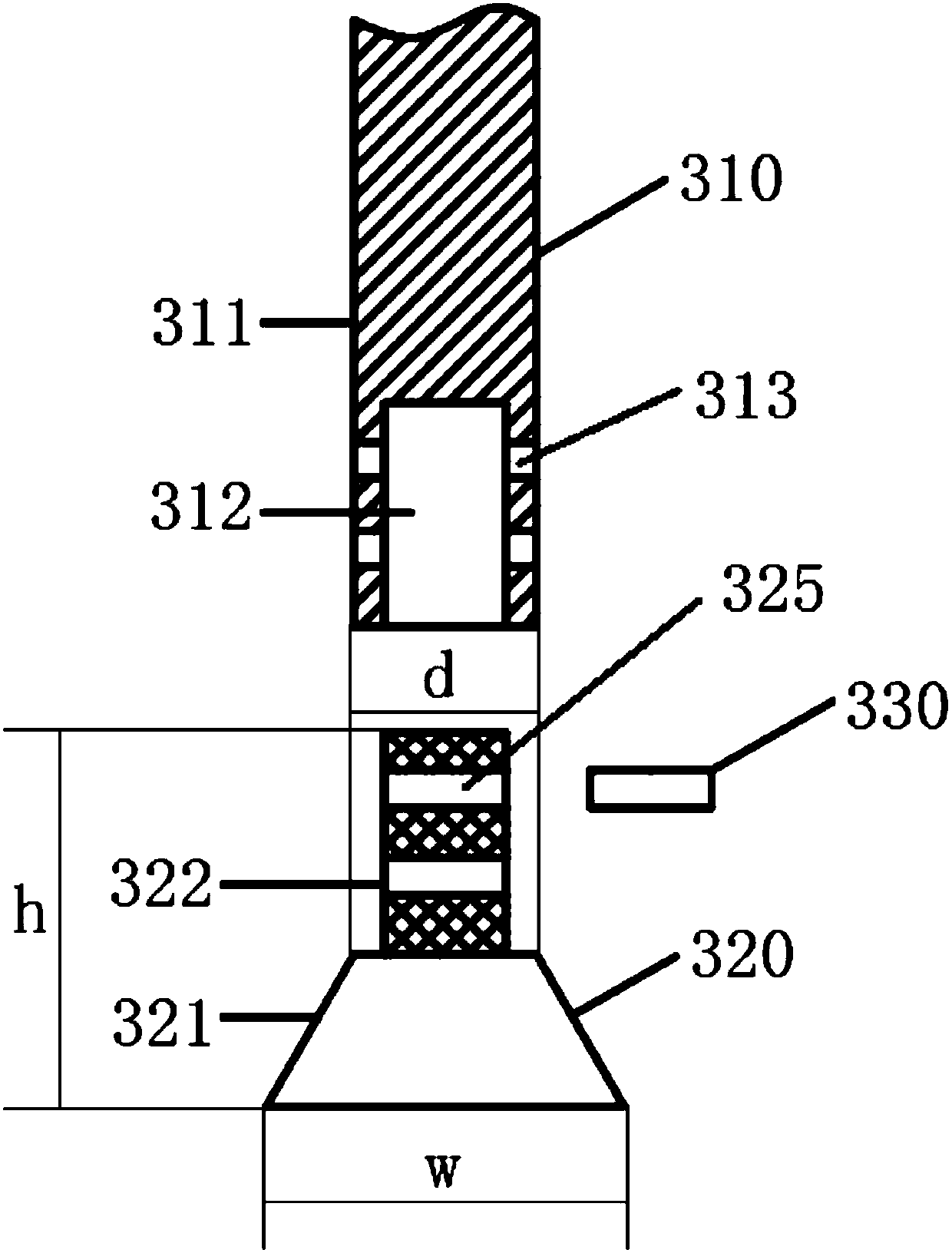

Machining method of reverse chamfers

The invention provides a machining method of reverse chamfers. The machining method includes the following steps that a reverse chamfering knife is assembled; a knife handle penetrates from one end ofa to-be-chamfered hole into an inner cavity in the other end of the to-be-chamfered hole; a knife bit of a cutting body being a truncated cone directly enters the inner cavity from the other end of the to-be-chamfered hole; the knife handle and the knife bit are fixedly connected; the reverse chamfers are machined; and the knife handle drives the knife bit to rotate, and the to-be-chamfered holeis subjected to reverse chamfer machining through a cutting blade on the side face of the truncated cone. The machining method has the beneficial effects that the proper type or dismounting and mounting manner of the chamfer machining knife is selected according to the requirements of different machining sizes and different limited spaces of products, thus, precise chamfering is carried out from bottom to top, the technical requirements of the products are met, the advanced level of the industry is reached, and the quality defects at different degrees that due to manual unreasonable operation,the interiors of parts are not uniformly chamfered, burrs are left, and internal scratches are generated are completely overcome.

Owner:SHANGHAI JIKEJIA PRECISION TECH

Fixed chamfering device for valve production

The invention discloses a fixed chamfering device for valve production and belongs to the technical field of valve processing. The fixed chamfering device for valve production comprises a workbench, arotating assembly, a fixing assembly, a lifting assembly, an extending assembly and an overturning assembly; the rotating assembly is arranged on the workbench; the fixing assembly is arranged at theworking end of the rotating assembly; the overturning assembly is arranged on the workbench; the overturning assembly is arranged on one side of the rotating assembly; the lifting assembly is arranged on the workbench; the lifting assembly is arranged on the other side of the rotating assembly; and the extending assembly is arranged at the working end of the lifting assembly. The steps of fixing,rotating, overturning and the like can be conducted on a valve through matching of the assemblies, and the valve is chamfered, so that the chamfering effect is better.

Owner:ANHUI ENDA VALVE MACHINERY CO LTD

A pvc pipe planer port equipment

Owner:LIANSU TECH DEV GUIYANG

A high-voltage ceramic capacitor ceramic dielectric chip on-line appearance inspection and chamfering device

ActiveCN106024429BHigh degree of automationIncrease productivityFixed capacitor dielectricCapacitor manufactureDielectricAutomatic transmission

The invention discloses a high-voltage ceramic capacitor ceramic dielectric chip on-line appearance detection and chamfering device which comprises an automatic transmission line, an appearance detection device, a deburring device, a computer and a nonconforming product box. A deburring station and an appearance detection station are arranged on the automatic transmission line. The deburring device comprises a positioning electromagnet. The appearance detection device is arranged on the automatic transmission line upstream or downstream the deburring device. The appearance detection device comprises vertical and horizontal probes. Vertical and horizontal probes are connected with the computer. The vertical probe is located right above a ceramic dielectric chip on the automatic transmission line. Through the structure, the on-line appearance detection and chamfering device can automatically detect the appearance of the ceramic dielectric chip, and has the advantages of automatic and online deburring, uniform chamfering, high automation degree, low labor intensity and high production efficiency.

Owner:苏州奥立登科技有限公司

Adjustment mechanism of gear-face profiling chamfering device

InactiveCN101422833BReduce use costSimple structureGear-cutting machinesGear teethEngineeringDepth direction

The invention relates to a regulating mechanism for a copying chamfering device on the end surface of a gear. According to the technical proposal provided by the invention, in the regulating mechanism, a copying contact is arranged on a Y-direction sliding seat which is connected with an X-direction sliding seat; a stop block is fixed on a lower fixed plate; a fourth screw rod is screwed in the threaded hole of the Y-direction sliding seat; the lower fixed plate is sheathed on the fourth screw rod and is fixed on the X-direction sliding seat; the X-direction sliding seat is connected with a Z-direction sliding seat; a first screw rod is screwed in the threaded hole of the X-direction sliding seat; a middle fixed plate is sheathed on the cylindrical surface of the first screw rod and is fixed on the Z-direction sliding seat; the Z-direction sliding seat is arranged on an upper fixed plate which is sheathed on a third screw rod; the third screw rod is screwed in the threaded hole of theZ-direction sliding seat; the upper fixed plate is fixed on a first slider; a nut is fixed in the inner hole of the first slider; and the first slider is arranged on a regulating frame which is fixedon a slider in a linear guide pair. The regulating mechanism can realize accurate control on the chamfering size, and the chamfering is carried out in full tooth uniformly along the tooth depth direction, thus improving the chamfering quality.

Owner:江苏南方机电股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com