Traction motor rotor commutator chamfering machine

A traction motor and commutator technology, which is applied in the field of metal processing, can solve the problems of uneven commutator chamfering and low chamfering efficiency, and achieve the effects of simple structure, high processing efficiency, and stable chamfering straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

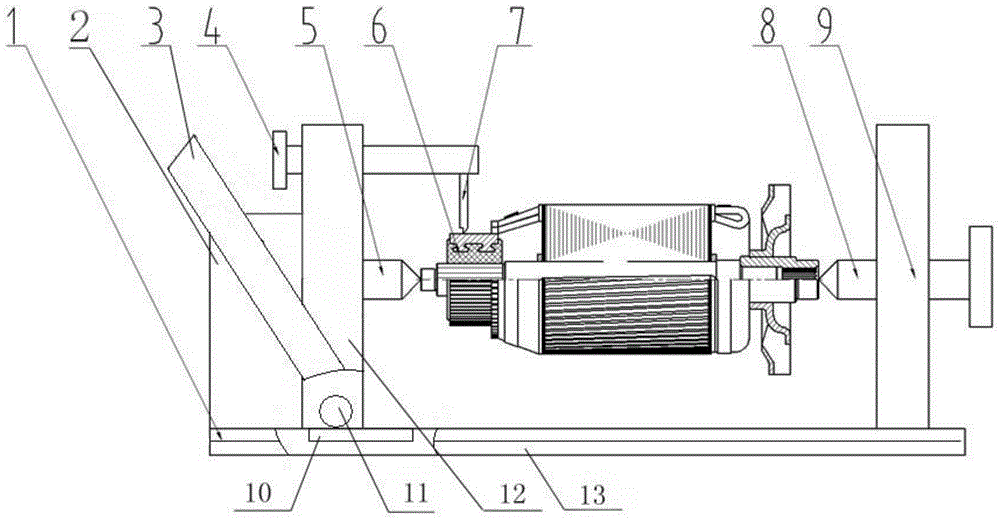

[0016] Such as figure 1 As shown, a traction motor rotor commutator chamfering machine includes a front bracket 2 and a rear bracket 9 fixed on the bottom bracket 13, the front bracket 2 is provided with a top 5, and the rear bracket 9 is provided with a moving top 8, The top 5 and the moving top 8 respectively fix the center of both ends of the workpiece, and adjust the moving top 8 to adapt to workpieces of different lengths.

[0017] Between the front bracket 2 and the rear bracket 9, there is a knife rest 12, the knife rest 12 is connected to the power rod 3, the power rod 3 is linked with the gear 11 at the bottom of the knife rest, the gear 11 meshes with the rack 10 at the bottom of the guide rail 1, and the power rod 3 is shaken When the gear 11 rotates, through the meshing of the gear 11 and the rack 10 , the rotational motion is converted into a linear motion, thereby driving the tool holder 12 to move along the guide rail 1 . The knife holder 12 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com