Welding chamfering machine for supporting seat of compressor

A technology for chamfering machines and compressors, applied in metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc., can solve the problems of increasing production and processing time, unfavorable long-term development of enterprises, and large labor requirements. The effect of reducing defective product rate, shortening production and processing time, and reducing production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to allow those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described with reference to the accompanying drawings.

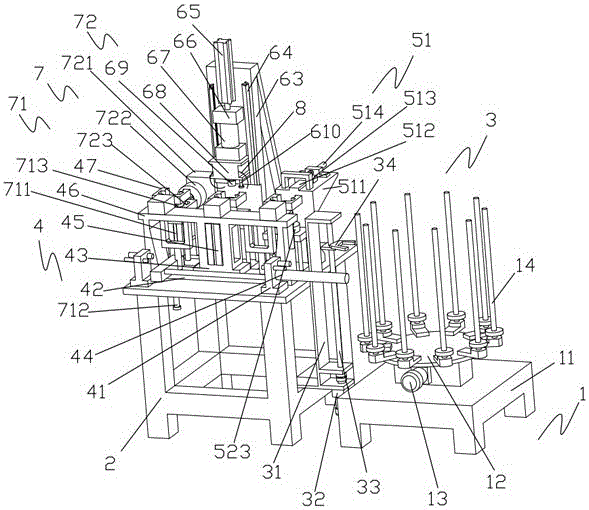

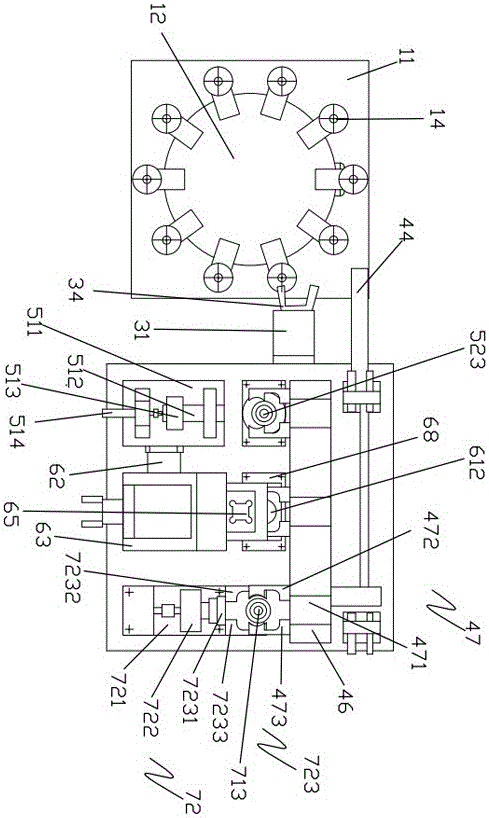

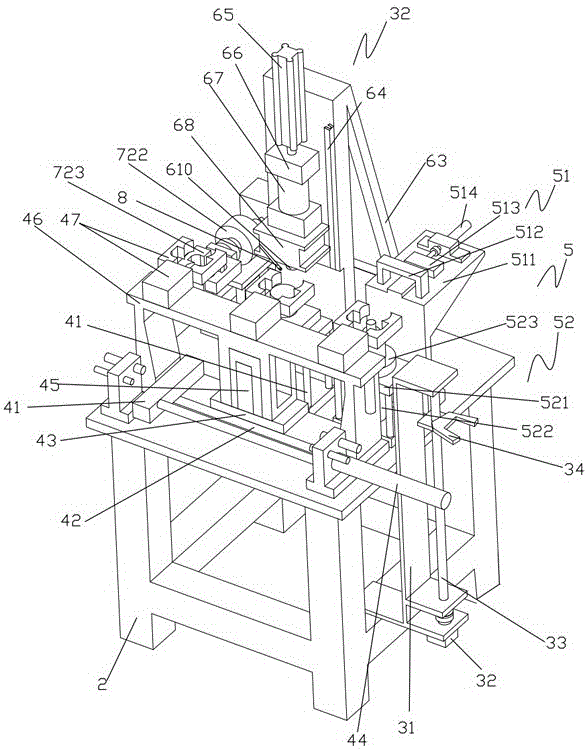

[0025] Such as Figure 1 to Figure 6 As shown, a compressor support welding chamfering machine includes a storage assembly 1 for storing the support and a frame 2 for installing parts; the upper end of the frame 2 is provided with a support The feeding mechanism 3 for feeding the seat, the moving mechanism 4 for moving the support, the alignment mechanism 5 for positioning the support, the chamfering mechanism 6 for processing chamfers on the support, and the The turning mechanism 7 that turns the processed support over, and the feeding mechanism 3, the alignment mechanism 5, the chamfering mechanism 6, and the turning mechanism 7 are on the same straight line, and are arranged at equal intervals to facilitate the moving mechanism to the feeding mechanism 3. The supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com