Manual chamfering device of magnetic ring

A technology of chamfering device and magnetic ring, which is applied in the manufacture of inductors/transformers/magnets, grinding machines, electrical components, etc. It can solve the problems of low production efficiency, missing chamfers, uneven chamfering, etc., and achieve high production efficiency and no The effect of omission and uniform chamfering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

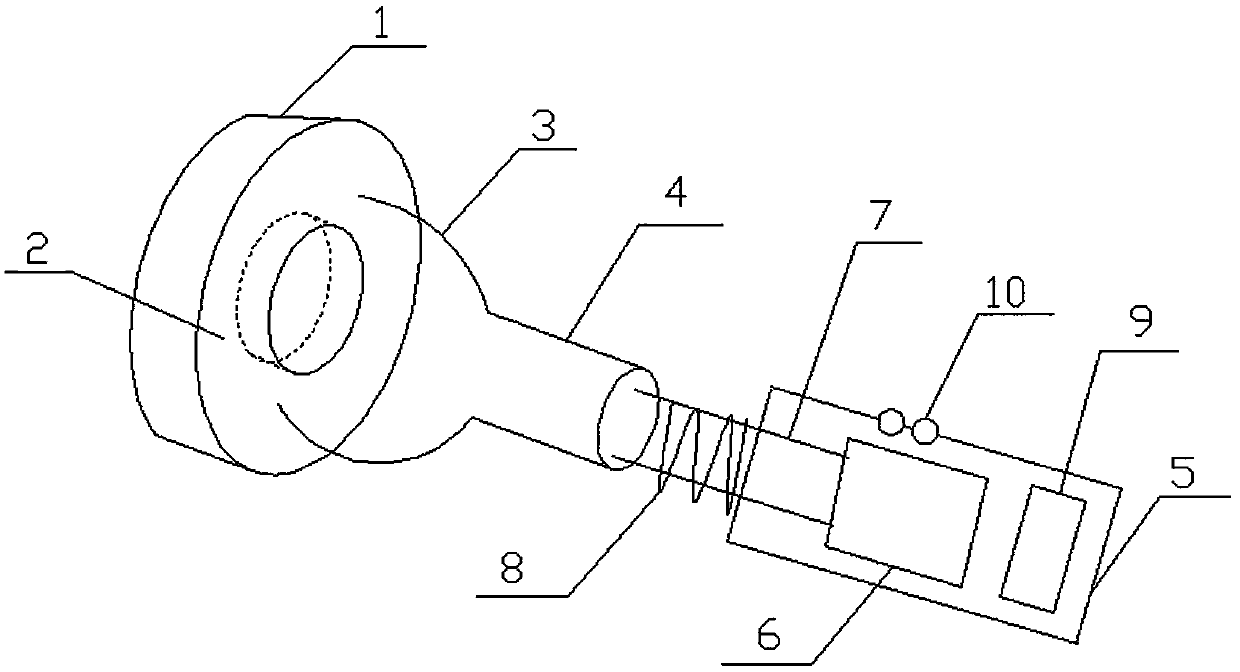

[0013] Such as figure 1 As shown, a magnetic ring manual chamfering device includes a ring 1 with a groove 2 in the middle and a handle 5 with a built-in motor 6. The groove 2 matches the end face of the magnetic ring to be chamfered. The bottom of the groove 2 is provided with a chamfering mechanism, the bottom of the ring 1 away from the groove 2 is fixed with a hollow threaded rod 4 with external threads through a connector 3, and the motor 6 is connected with a The rotating shaft 7, the extending end of the rotating shaft 7 is provided with an external thread 8 matching the hollow threaded rod 4, and the handle 5 is also provided with a switch button 10. The rotating shaft 7 is threadedly connected with the hollow threaded rod 4 and is detachable, and the corresponding ring 1 can be replaced according to the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com