Machining method of reverse chamfers

A processing method and reverse technology, applied in the key manufacturing process of key mechanical parts, to achieve the effects of reducing scrap loss, simple fixing and disassembly, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

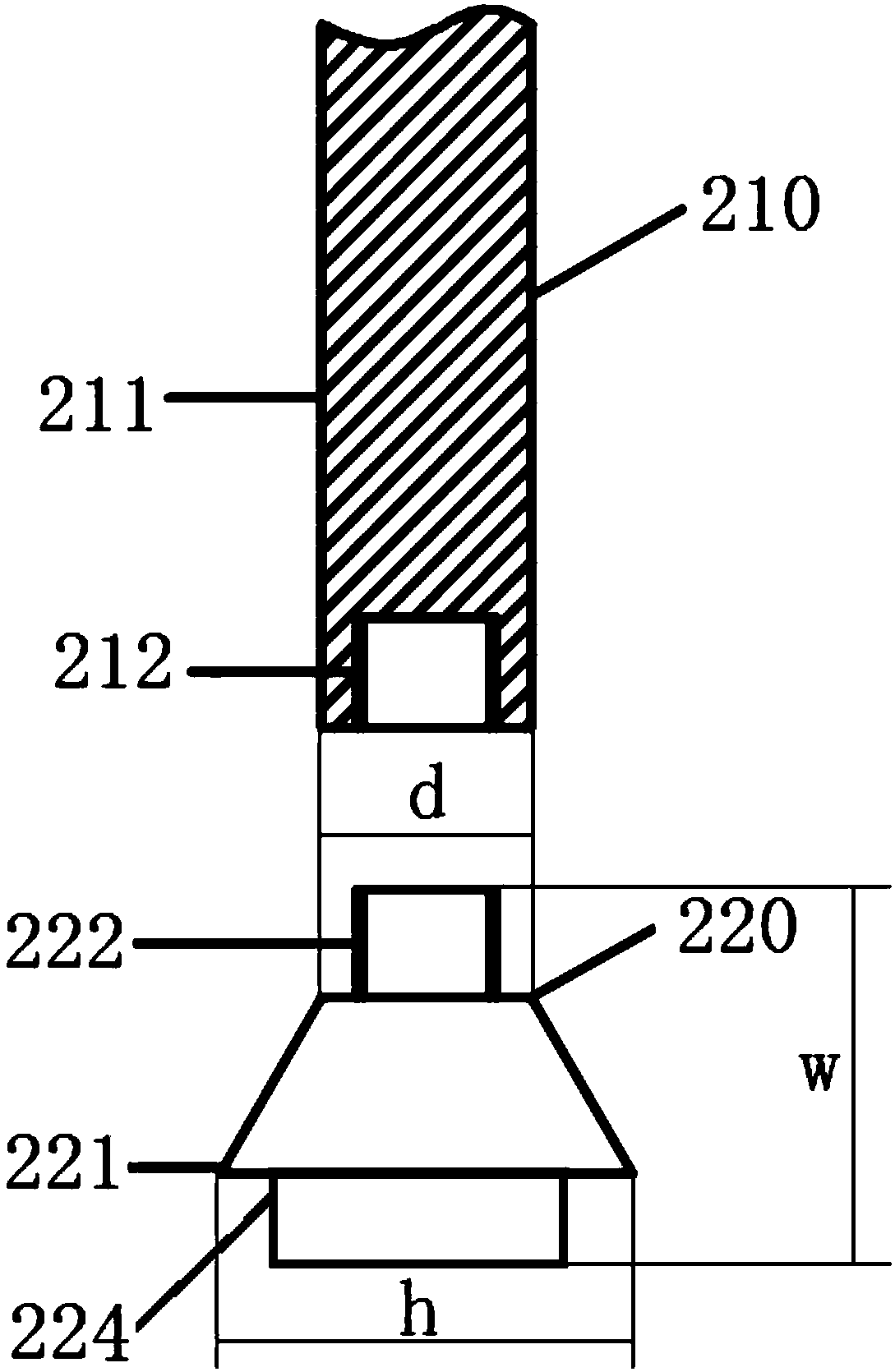

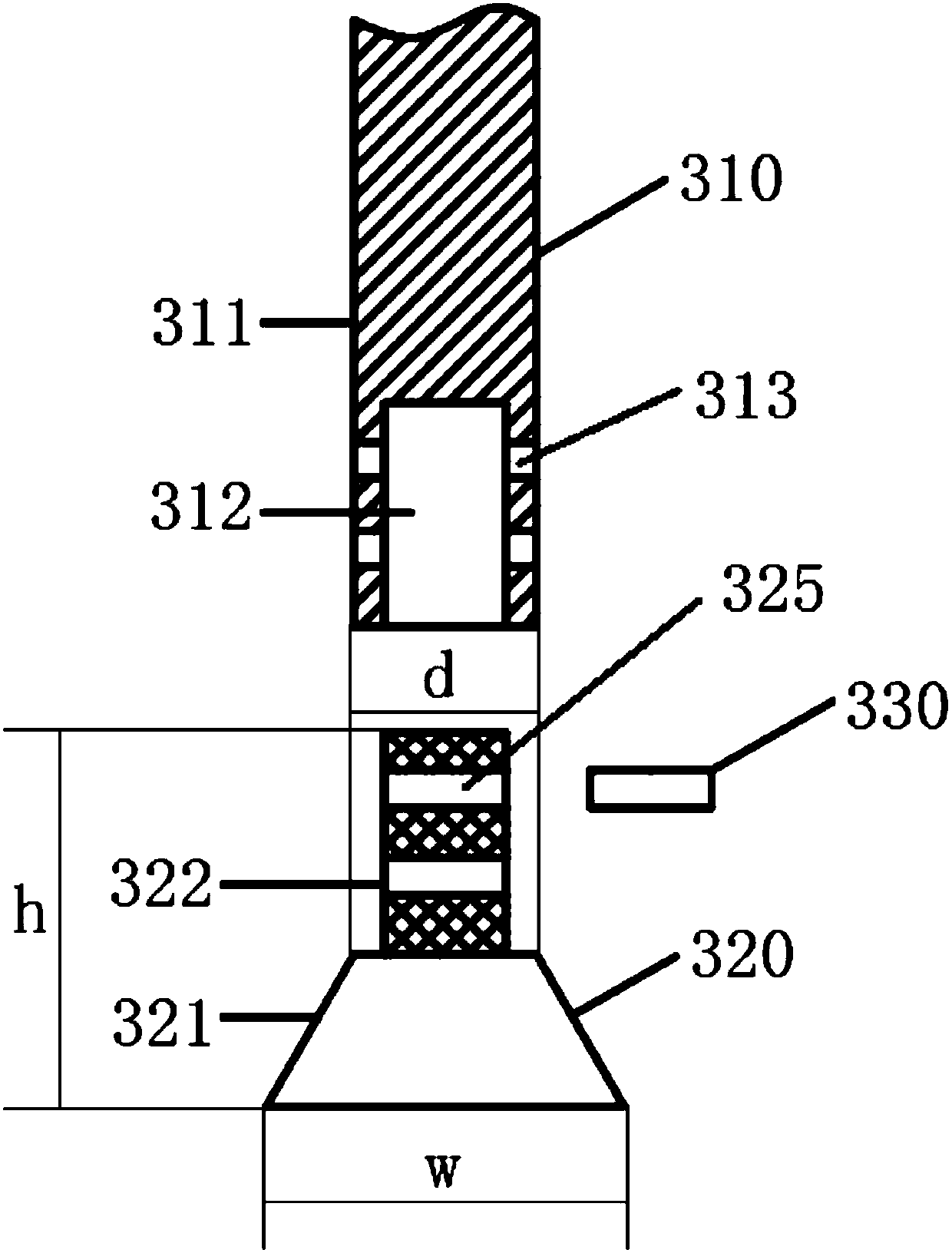

[0024] A processing method of reverse chamfering provided by the present invention adopts three kinds of reverse chamfering knives, which are respectively: handle-locked reverse chamfering knife, cutter head-locked reverse chamfering knife and bolt-fixed Type reverse chamfering knife. The structure of the three kinds of knives will be described first.

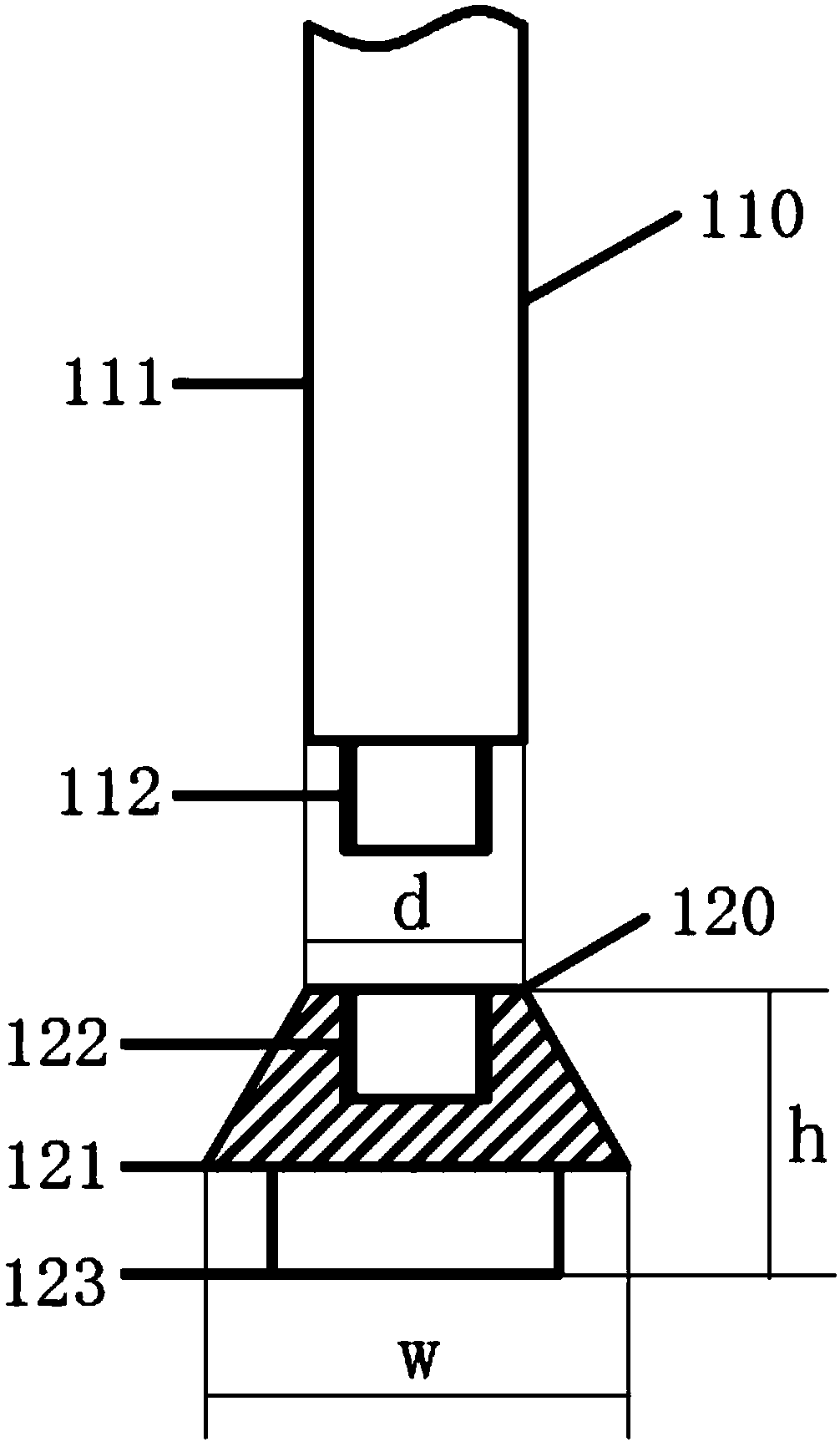

[0025] figure 1 It is the structural diagram of the shank locking type reverse chamfering tool.

[0026] like figure 1 As shown, the shank-locking reverse chamfering knife includes: a shank 110 and a knife head 120 . The handle 110 includes: a handle rod 111 and an external thread 112 . The outer thread 112 is at the bottom of the handle 111 , and the outer diameter of the outer thread 112 is smaller than the outer diameter of the handle 111 . The cutter head 120 is composed of a cutting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com