Chamfering mechanism capable of eliminating deviation

A technology of chamfering mechanism and deviation, applied in the field of chamfering mechanism, can solve the problems of easy deviation, easy generation of burrs, poor chamfering effect, etc., so as to eliminate concentricity deviation and height deviation, improve production efficiency and reduce production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The existing chamfering method is prone to deviation, which makes it easy to generate new burrs, and the chamfering effect is poor. Therefore, the present invention proposes a new solution. For a clearer representation, the present invention will be described in detail below in conjunction with the accompanying drawings.

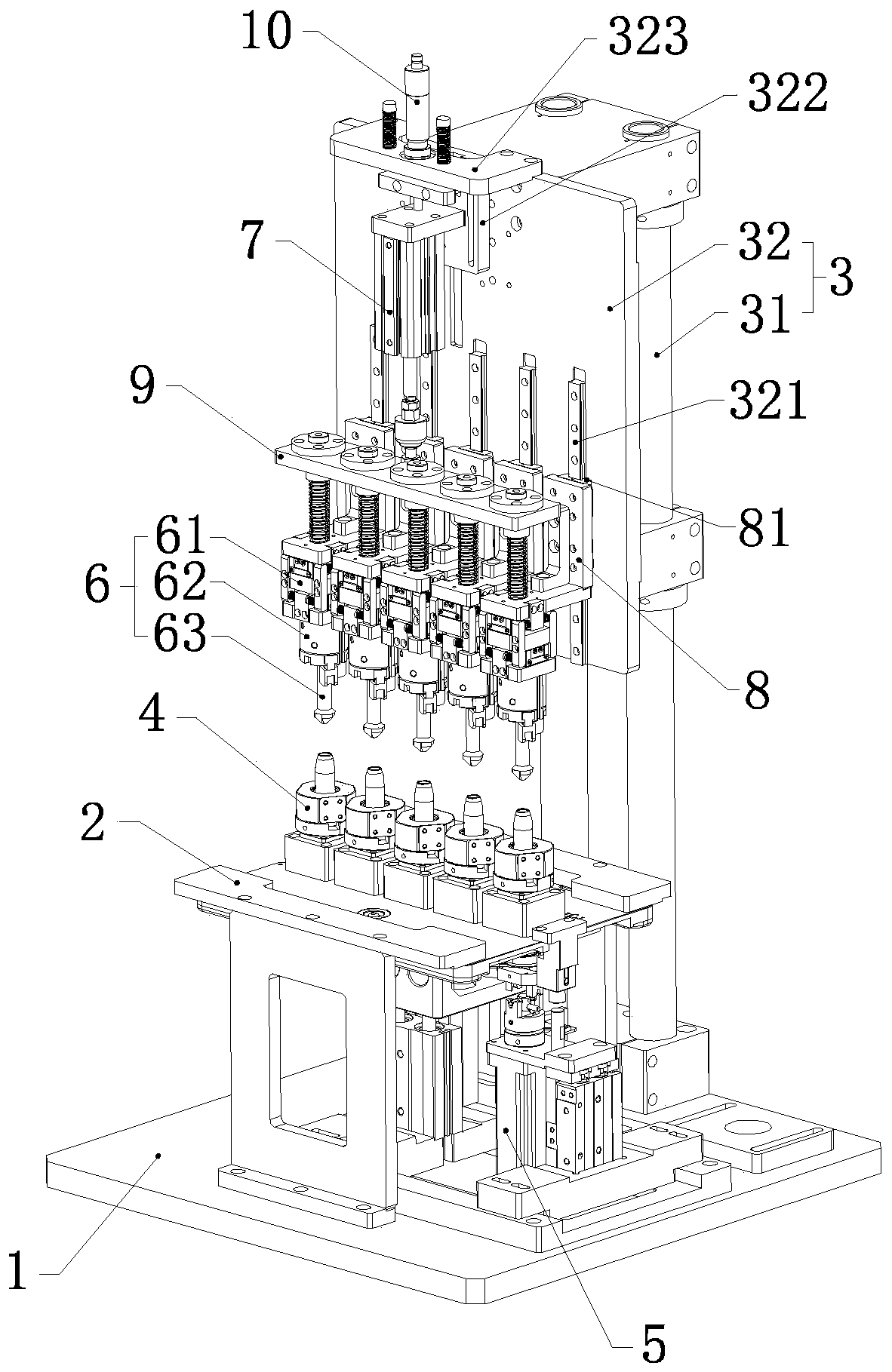

[0026] see Figure 1-4 , a chamfering mechanism that can eliminate deviations, including a frame, the frame includes a base 1, a mounting base 2 and a support assembly 3, the mounting base 2 is fixedly erected in the middle of the base 1, and the support assembly 3 It is fixedly arranged at the rear end of the base 1 .

[0027] The mounting base 2 is provided with at least one rotating jig 4 for installing the product to be processed, and the base 1 is fixed with a first driving device 5 for driving the rotating jig 4 to rotate.

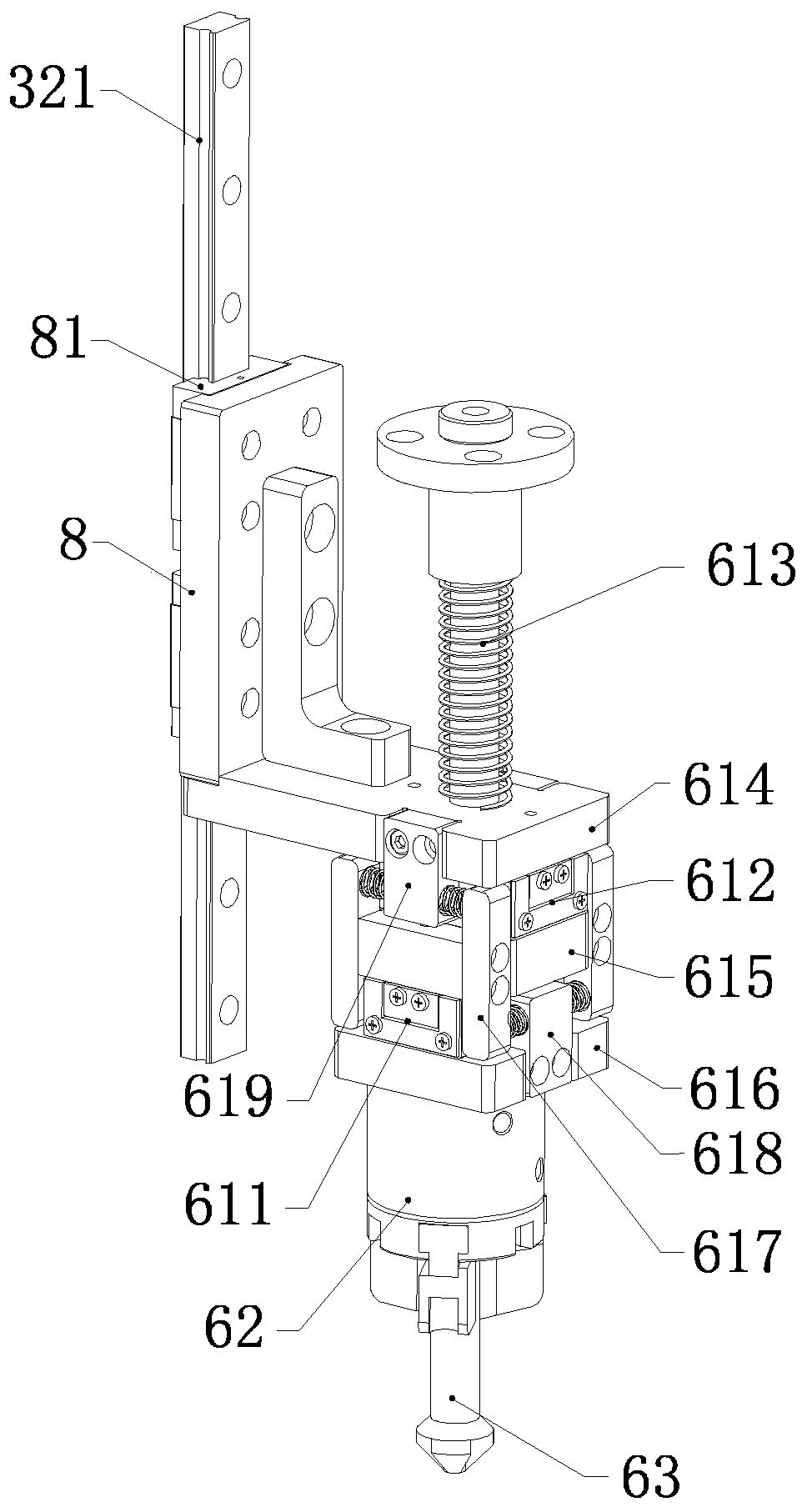

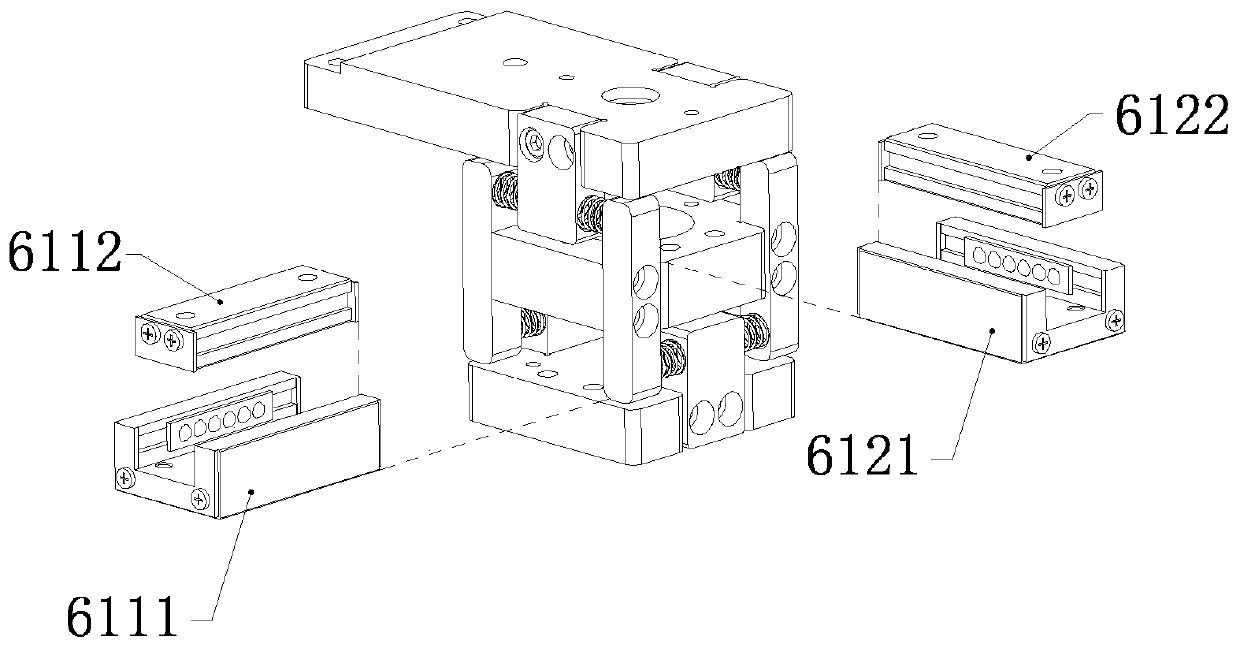

[0028] A floating cutter assembly 6 corresponding to the rotary jig 4 is slidably mounted on the support assembly 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com