Automatic paint coating method for side face of aluminum-wood composite board

A coating method and composite board technology, which can be used in wood processing appliances, metal processing equipment, manufacturing tools, etc., can solve problems such as unsightly appearance, time-consuming removal, and easy removal by mistake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below with reference to the accompanying drawings.

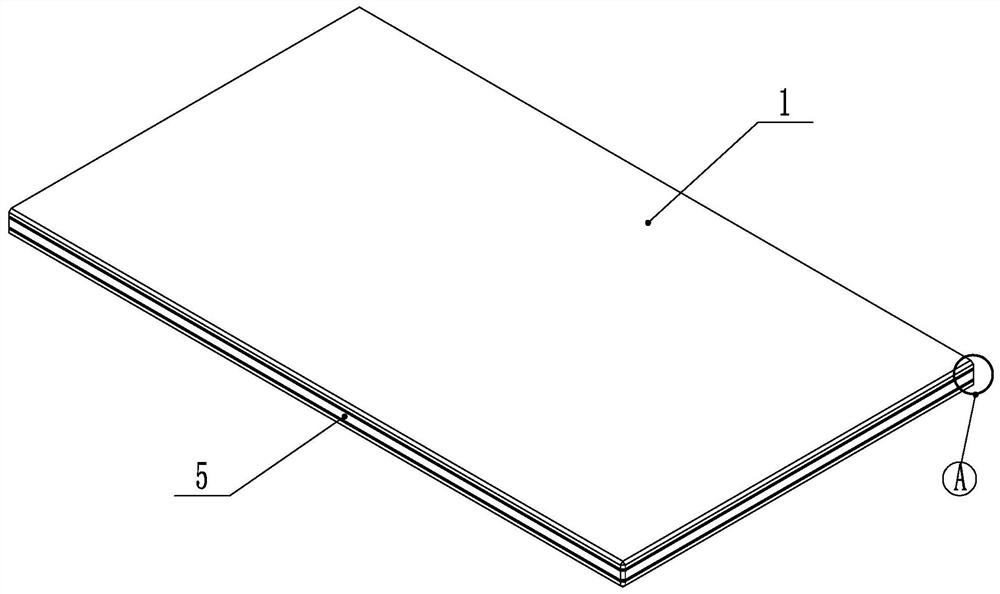

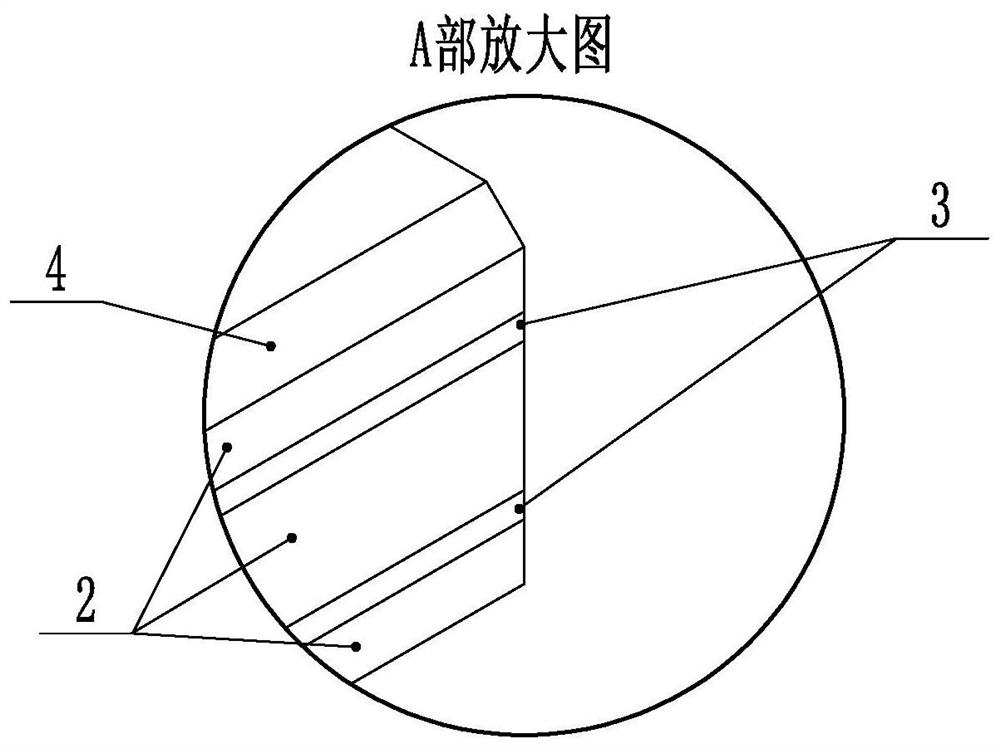

[0036] Such as Figure 1-4 As shown, the aluminum wood composite plate 1 includes an aluminum layer 3 and a lignaterial layer 2, an aluminum layer 3, and a wood material layer 2, an aluminum layer 3 and a wood material layer 2 are bonded by strong adhesion.

[0037] Such as Figure 5 As shown, the aluminum composite panel side paint automatic painting method, including the following steps:

[0038] S1: Place the finished aluminum composite plate on the dam saw, saw the required size aluminum composite plate 1;

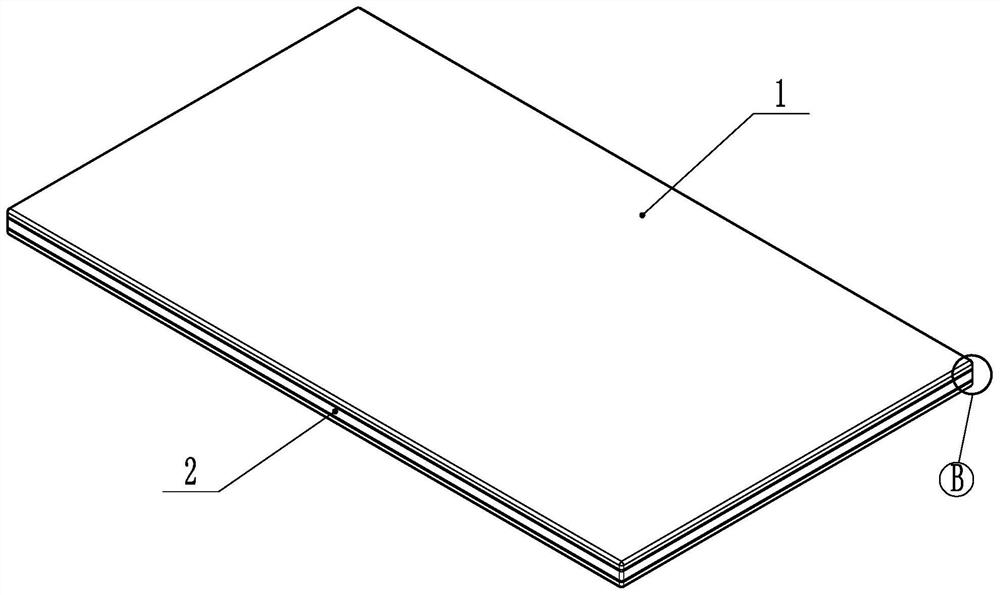

[0039] S2: The aluminum composite plate 1 side surface 5 is made to fill the aim, by filling the gap, the holes are flat 5 side surfaces of the aluminum composite plate 1;

[0040] S3: The aluminum composite plate 1 side 5 is first grinded, remove the burr, and ensure that the aluminum composite plate 1 side 5 is smooth;

[0041] S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com