Method for producing wooden floor with platinum crystal surface

A production method and technology for wood floors, which are applied to devices for coating liquid on surfaces, wood treatment, and humidity-conditioning wood, etc., can solve the problems of wood floors that do not have high wear resistance, high adhesion and environmental protection, and achieve improved clarity. , Increase the penetration performance, the effect of filling and plumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

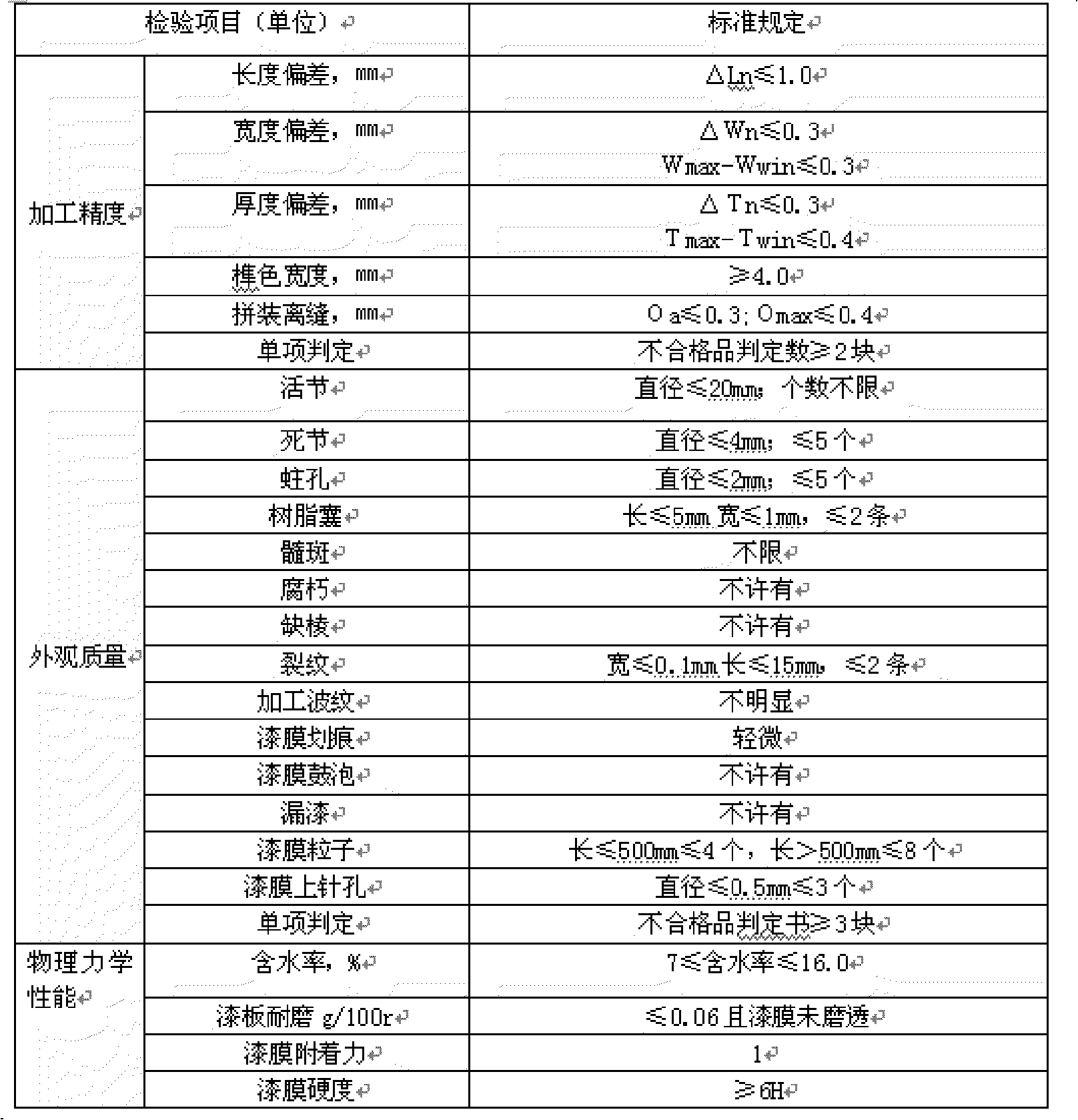

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention. The wood in this example is the disc bean tree species, and the disc bean is African wood with an air-dry density of 0.10g / cm3 . Disc bean wood is shiny, no special smell, staggered texture, thick and uniform structure, heavy wood, hard texture, high strength, dry shrinkage, good sanding and dyeing performance. Disc bean wood is rich in resources, and it is a mid-priced species among imported woods, and it is also the most commonly used raw material for flooring, so it is representative to choose disc bean wood as the object. The specifications of the disc bean board blank are: length × width × thickness = 930 × 133 × 23mm, and the average initial moisture content is 39.17%.

[0024] The production steps include drying and curing of floor blanks, blank processing, priming and painting. By drying and curing the floor blanks, the moisture content of the floor blanks is 8-14%, generally 12-14% in the southern region, and 8-11% in the north...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com