Glass fiber mesh reinforcement, external thermal insulation and anti-cracking structure of wall and its construction method

A technology for external wall insulation and reinforcement, applied in the direction of insulation, building components, etc., can solve the problem of weak bonding of different media, achieve good fixing effect, good tensile performance, and absorb noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

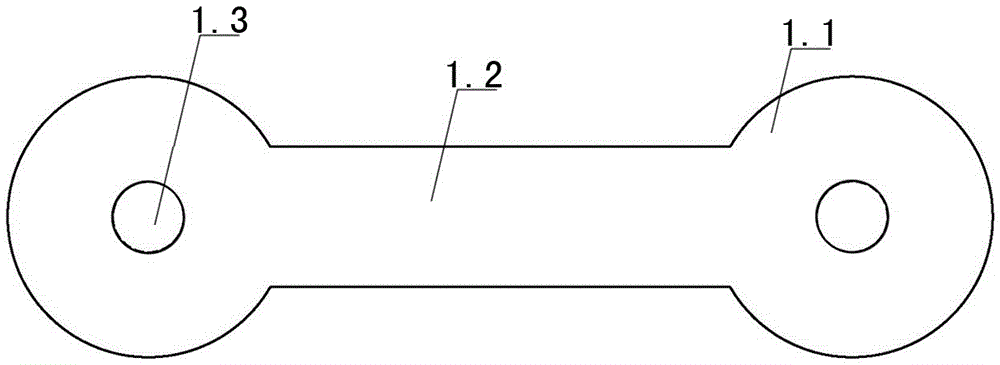

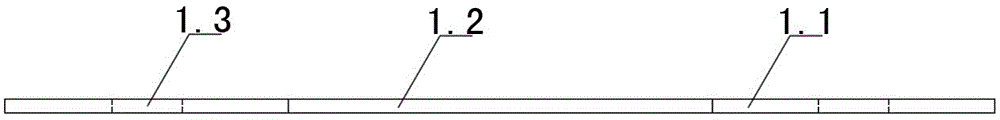

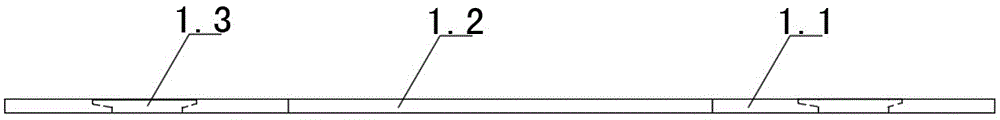

[0036] Examples see figure 1 , Figure 4 As shown in this glass fiber mesh reinforcement, the glass fiber mesh reinforcement 1 is in the shape of a double fixed piece, and the two fixed pieces are connected by a bridge 1.2, and the center of each fixed piece is opened. Through the screw hole 1.3 of the screw 2; the material of the glass fiber mesh reinforcement 1 is nylon, that is, polyamide fiber, and the surface of the glass fiber mesh reinforcement is rough, and the glass fiber mesh reinforcement has a total length of 70 mm and a thickness of 0.6 mm; The piece 1.1 is circular with a diameter of 20mm; the width of the bridge 1.2 is 10mm and the length is 30mm; the screw is made of nylon self-tapping screw made of the same material as the fixed piece, the outer diameter of the thread is 4mm, the pitch is 2.4mm, and the screw cap is flat ten Glyph, diameter 8mm, screw length 40-60mm; in order to ensure reliable connection between the glass fiber mesh reinforcement and the ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com