A system for improving wheel-rail adhesion of trains

A technology of adhesion and train wheels, which is applied to locomotives and other directions, can solve the problems that it is difficult for sand to enter between the wheel and rail, increase the adhesion of wheel and rail, and the adhesion coefficient of wheel and rail is small, so as to achieve easy operation and stable adhesion of wheel and rail , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

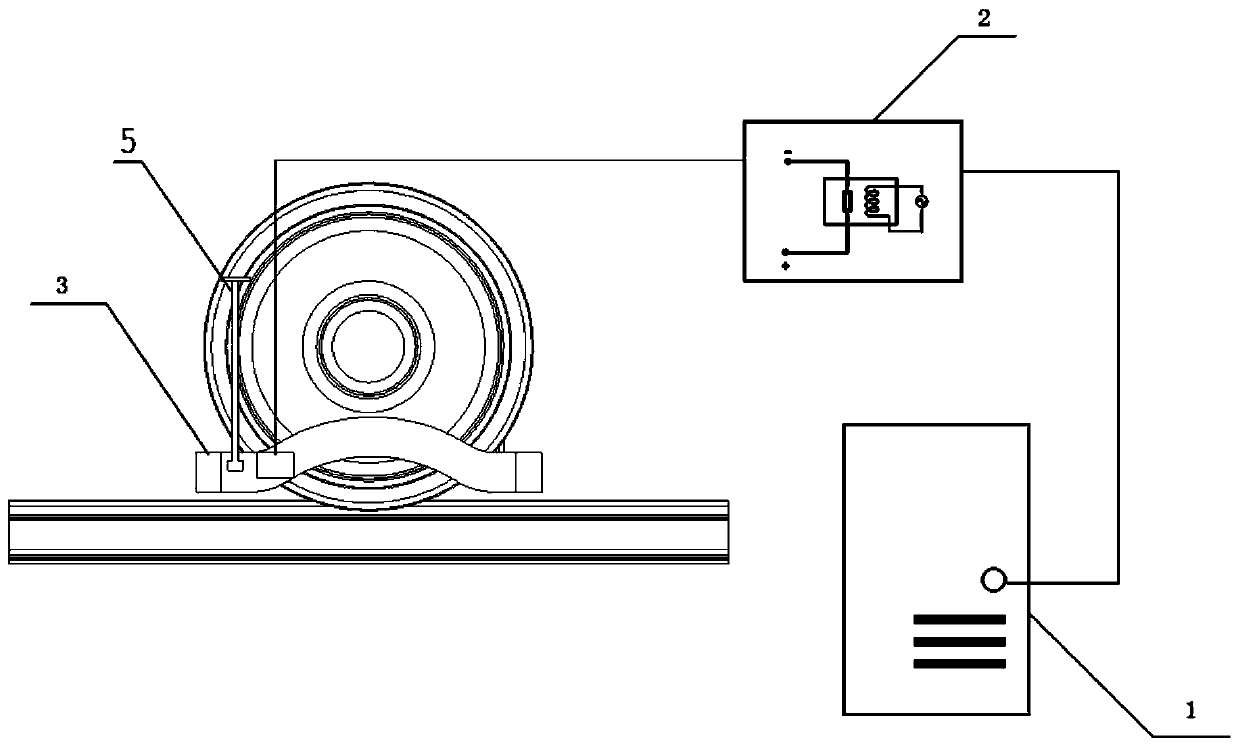

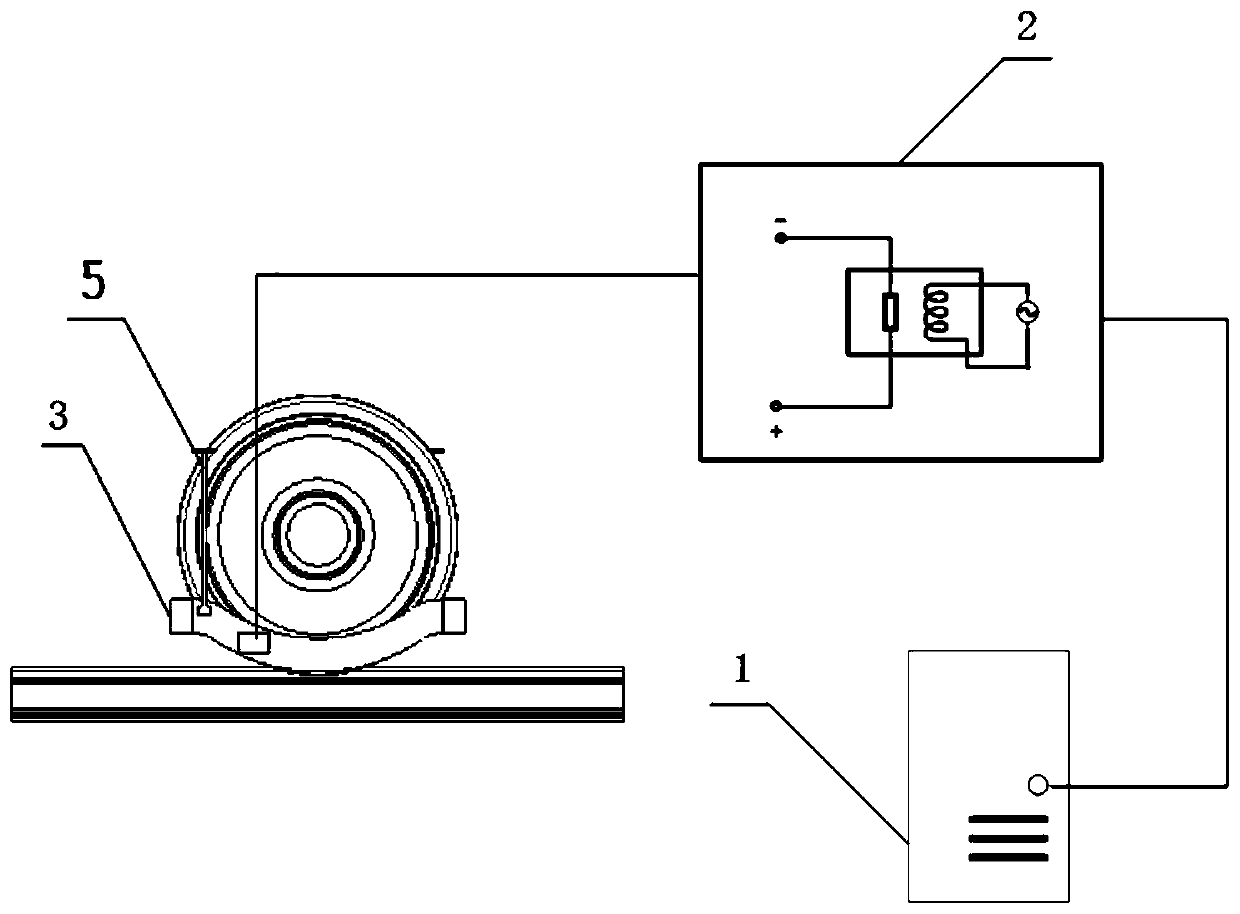

[0034] A system for improving the wheel-rail adhesion of a train, comprising a control assembly 1, a power supply 2, and an electromagnetic coil assembly 3 connected in sequence through lines, the electromagnetic coil assembly is wrapped around the train wheels, and the power supply 2 is used for Provide current to the electromagnetic coil assembly 3, at this time, the train wheel and the surrounding electromagnetic coil assembly form a large electromagnet, forming a magnetic field near the train wheel and the track, and the wheels surrounding the electromagnetic coil generate electromagnetic adsorption force on the rail, thereby increasing the strength of the vehicle. The vertical force acting on the rail, under the condition of the original wheel-rail adhesion coefficient, realizes the effect of improving the wheel-rail adhesion of the train. The control component is used to issue instructions to the power supply, and adjust the output current of the power supply through the i...

Embodiment 2

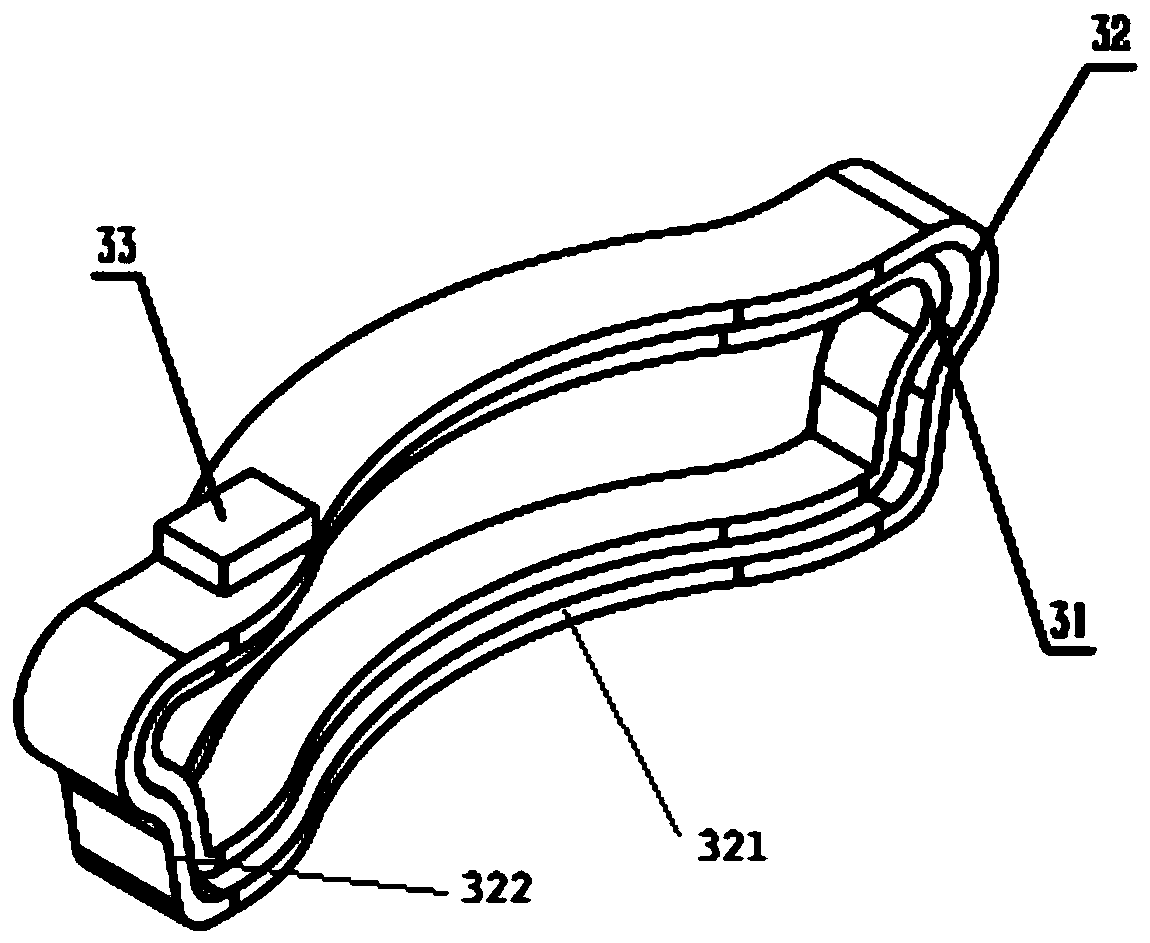

[0043] Different from Embodiment 1, this embodiment adopts another shape and structure of the coil housing 32 .

[0044] The electromagnetic coil assembly 3 includes an excitation coil 31 , a coil casing 32 and a junction box 33 , the excitation coil 31 is wound in the coil casing 32 , and the junction box 33 is arranged on the coil casing 32 . The excitation coil 31 and the coil casing 32 are annular structures, which include long sides 321 non-contactingly arranged on both sides of the rim of the train wheel and short sides 322 non-contactingly arranged on both sides of the wheel tread. The long side 321 described is a downward convex "saddle" shape structure, see image 3 , Figure 4 and Figure 5 . During the operation of this solution, the excitation coil 31 bends downward along the edge of the lower rim of the wheel, ensuring a uniform gap between the excitation coil 31 and the wheel rim, rim, and tread, thereby reducing magnetic flux leakage.

Embodiment 3

[0046] Different from Embodiment 1, the boom 5 is further improved into a telescopic boom, so as to realize the convenience of specific adjustment. For the specific structure, please refer to Figure 6 . The boom 5 is a telescopic boom, and the telescopic boom includes a sleeve 51, a rod 52 and a mounting seat 53, and the sleeve 51 is connected to the mounting seat 53 and is fixed to the rail of the train through the mounting seat 53. On the bogie frame, one end of the rod 52 is movably nested in the sleeve 51 to realize expansion and contraction, and the other end is connected to the coil casing 32 . The electromagnetic coil assembly (3) matched in this embodiment is a horizontal annular structure, wherein the excitation coil 31 also adopts a horizontal winding form. For the telescopic suspension rod in this embodiment, it can be installed according to The specific structure of the train and the standard of the track to make the adjustment of the corresponding upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com