Wheel disc type cable sheath chamfering cutter and chamfering method

A technology of cable sheath and chamfering tool, which is applied in the direction of cable installation, cable installation device, dismantling/armoring cable equipment, etc. It can solve the problem of poor chamfering or chamfering effect, damage to the internal structure of the cable, and cable insulation Hard layer and other problems, to achieve uniform chamfering, simple structure, the effect of protecting the wire core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A kind of roulette type cable sheath chamfering tool of the present invention will be further described below in conjunction with accompanying drawing:

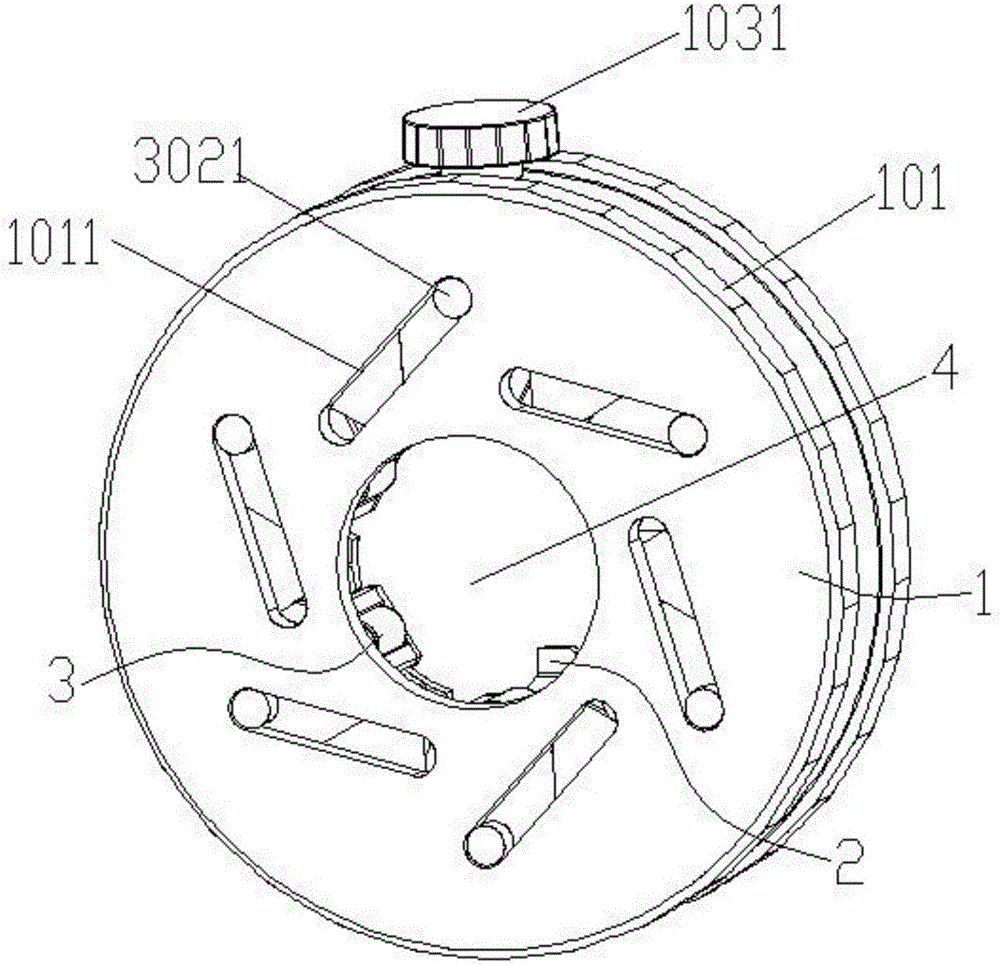

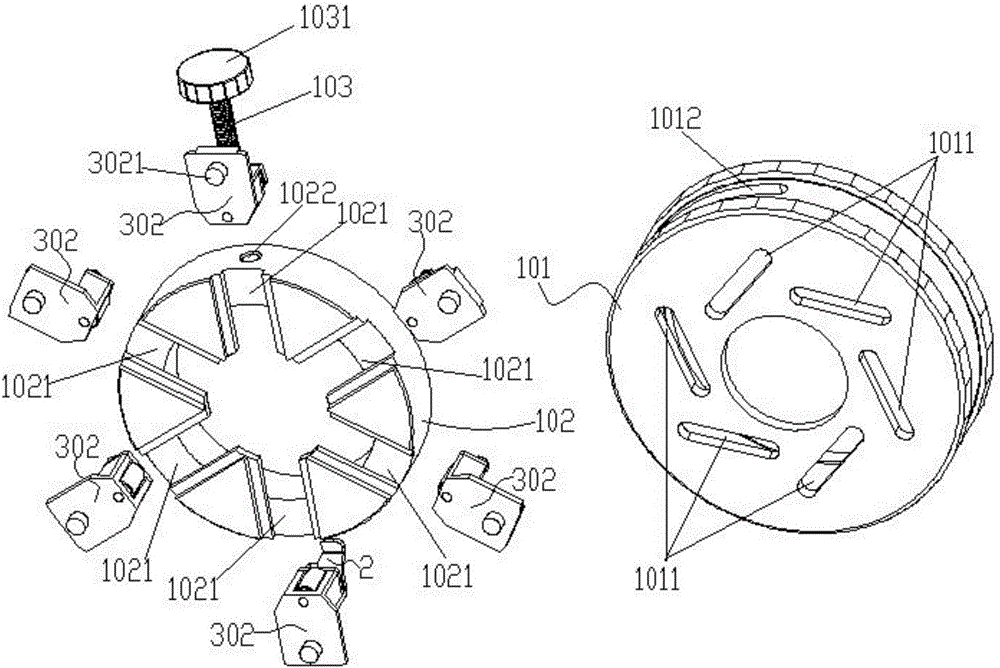

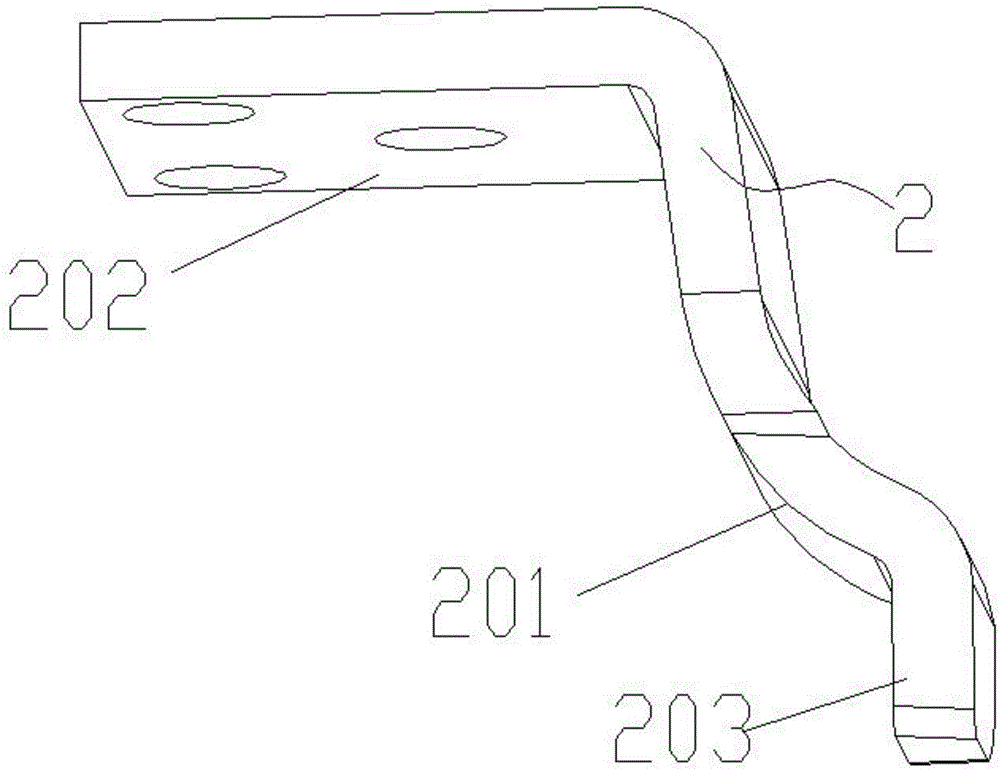

[0028] Such as Figure 1-4 Shown, a kind of roulette type cable sheath chamfering tool comprises ring tool rest 1, two chamfering blades 2 and six clamping devices 3 arranged on the ring tool rest 1, these six clamping devices 3 along The ring tool holder is evenly arranged in the circumferential direction; the clamping device 3 includes a locking block 302 and a clamping part 301 installed at the end of the locking block 302, and the clamping parts 301 of the six clamping devices 3 are surrounded by a clamping cable The clamping space 4, the locking block 302 is movably connected with the ring tool holder 1 through a locking device, and the locking device can adjust the locking block 302 to reciprocate synchronously along the radial direction of the ring tool holder 1 to adjust the clamping space 4 The size of the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com