Fibre reinforced plastic (FRP) reinforcing rectangular column with corner reinforcement and construction method thereof

A construction method and technology of rectangular columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of stress concentration at the chamfered part without improvement, the ratio of reinforcement efficiency/cost is reduced, and the reinforcement effect of FRP is difficult to control, etc., to achieve outstanding economy. , the effect of improving reinforcement efficiency and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

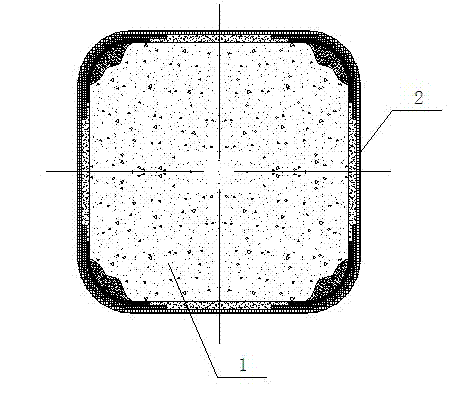

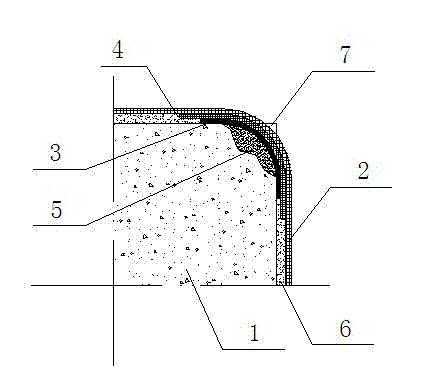

[0037] A FRP reinforced rectangular column with corner reinforcement, such as figure 1 , figure 2 As shown, it is characterized in that the FRP reinforcement layer (2) of the rectangular column (1) is provided with prefabricated chamfers (3) and corner reinforcements (4).

[0038] The prefabricated chamfer (3) is made of plastic, fiber reinforced plastic (FRP) or sheet metal.

[0039] The corners are reinforced with fiber reinforced plastic (FRP) or sheet metal.

[0040] When the prefabricated chamfer (3) is made of fiber reinforced plastic (FRP) or sheet metal, the prefabricated chamfer (3) can be directly used as a corner reinforcement (4).

[0041] The prefabricated chamfer (3) is pasted on the corner of the rectangular column (1) by the repair material (5).

[0042] The construction method is carried out in the following two ways:

[0043] method one:

[0044] The first step: according to the design radius of curvature of the chamfer, chip off the concrete at the 4 corners (7) of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com