Correction-free numerical control chamfering algorithm based on polar coordinate machine tool

A polar coordinate and chamfering technology, applied in the field of correction-free numerical control chamfering algorithm, can solve the problems of high customization cost, low efficiency of manual correction method, automatic centering tooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a correction-free numerical control chamfering algorithm based on a polar coordinate machine tool, comprising the following steps:

[0037] Step 1: Use a trigger probe to measure on two planes, and use the least square method to obtain the gear rotation center and axis position;

[0038] Step 2: Establish a mathematical model of the conversion relationship between the chamfering processing coordinate system and the workpiece coordinate system;

[0039] Step 3: Obtain the position of the upper end surface of the gear by collecting points, as a basis to determine the position of the chamfering target profile, and convert to the chamfering processing coordinate system;

[0040] Step 4: Obtain the intersection line between the gear chamfering target end plane and the chamfering tool;

[0041] Step 5: Calculate the tool position for chamfering according to the principle of space envelope.

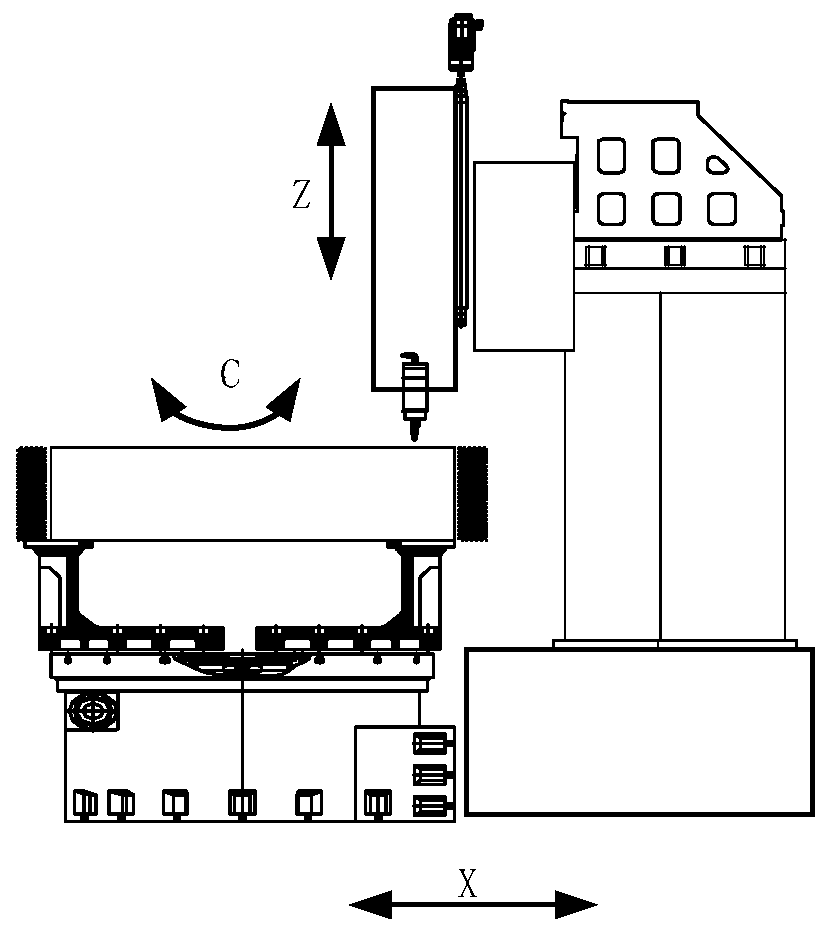

[0042] In this embodiment, the installation position of the ...

Embodiment 2

[0046] As the second embodiment of the present invention, in order to obtain the gear rotation center and axis position accurately, the inventors improved the method of step 1. As a preferred embodiment, the gear rotation center and axis position are obtained in step 1 The specific method is as follows:

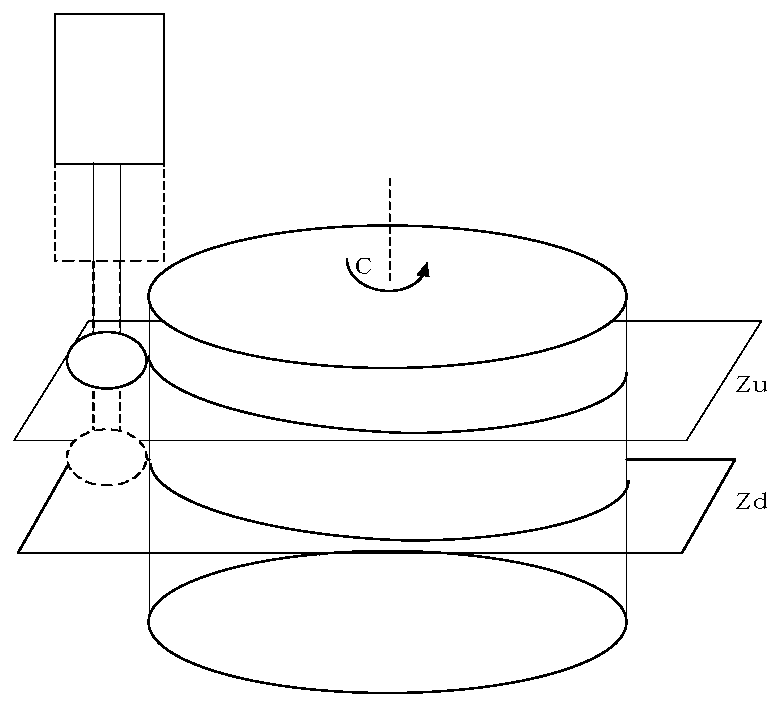

[0047] S1-1. Use a trigger probe concentric with the chamfering tool, take the upper and lower Z value planes Zu and Zd, rotate the C axis to measure the outer circle of the gear, and get 5 data points for each plane, namely (ρ u1 , θ u1 ), (ρ u2 , θ u2 )……, (ρ u5 , θ u5 ), (ρ d1 , θ d1 )(ρ d2 , θ d2 )……, (ρ d5 , θ d5 );

[0048] S1-2. Convert the measured points into the three-dimensional Cartesian coordinate system SO(O-X, Y, Z), where the Z axis coincides with the rotary axis of the turntable, and the X axis coincides with the X axis of the machine tool, so that (x u1 ,y u1 ,z u1 ),..., (x u5 ,y u5 ,z u5 ), (x d1 ,y d1 ,z d1 ),..., (x d5 ,y d5 ,z d5 ...

Embodiment 3

[0065] As the second embodiment of the present invention, in order to facilitate the conversion between the chamfering processing coordinate system and the workpiece coordinate system, the inventors improved the method of step 2. As a preferred embodiment, the chamfering processing coordinate system is established in step 2 The specific method of the mathematical model of the conversion relationship with the workpiece coordinate system is as follows:

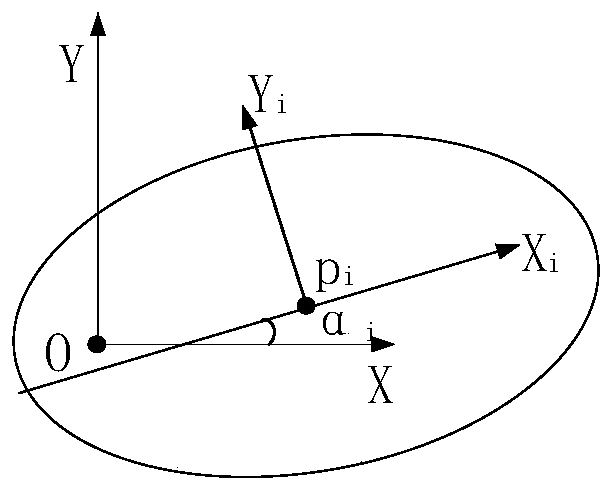

[0066] S2-1. Let the center point of any Z plane gear be Pi(x i ,y i ,z i );

[0067] S2-2. Establish a coordinate system SP(Pi-Xp, Yp, Zp);

[0068] S2-3, coincide the direction of the Zp axis in the coordinate system SP established in step S2-2 with the vector v.

[0069] In this example, if Figure 4 As shown, the transformation relationship formula of the coordinate system SO and SP is as follows:

[0070]

[0071]

[0072] Mpo=Rpo*Tpo

[0073] Mop = Mpo -1

[0074] in,

[0075]

[0076]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com