Chamfering device of thin wall cylinder part

A thin-walled cylinder and chamfering device technology, applied in positioning devices, metal processing mechanical parts, clamping and other directions, can solve the problems of deformation of thin-walled cylindrical parts, high pressure on the side wall of cylindrical parts, and reduced yield rate, etc., and achieve chamfering. Uniform, good chamfering quality and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

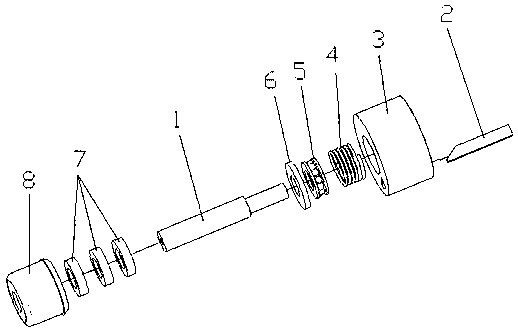

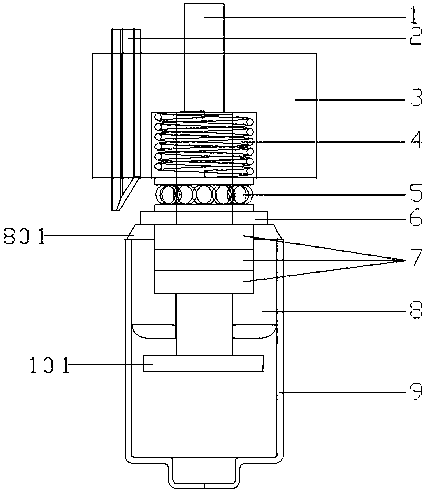

[0018] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine Figure 1-Figure 2 The accompanying drawings describe the present invention in further detail.

[0019] refer to Figure 1-2 The shown chamfering device for thin-walled cylindrical parts includes a main shaft 1, a tool 2, a tool holder 3, a spring 4, a plane bearing 5, a gasket 6, a rolling bearing 7, and a workpiece positioning body 8, and the tool 2 is installed on the tool holder 3. , the tool holder 3 is installed on the main shaft 1 and can be rotated by the main shaft 1, thereby driving the tool 2 to rotate around the main shaft 1, the workpiece positioning body 8 is connected to the main shaft through a plurality of rolling bearings 7, and the top of the workpiece positioning body 8 is also provided with a A spacer 6 for limiting the rolling bearing 7, a spring 4 and a plane bearing 5 are also arranged between the workpiece positioning bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com