Stainless steel harness wire cleaning and grinding device

A grinding device, stainless steel technology, applied in the direction of grinding machines, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of many stamping processes, difficult to achieve, high labor costs, etc., to achieve smooth heald surface and stable heald quality , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

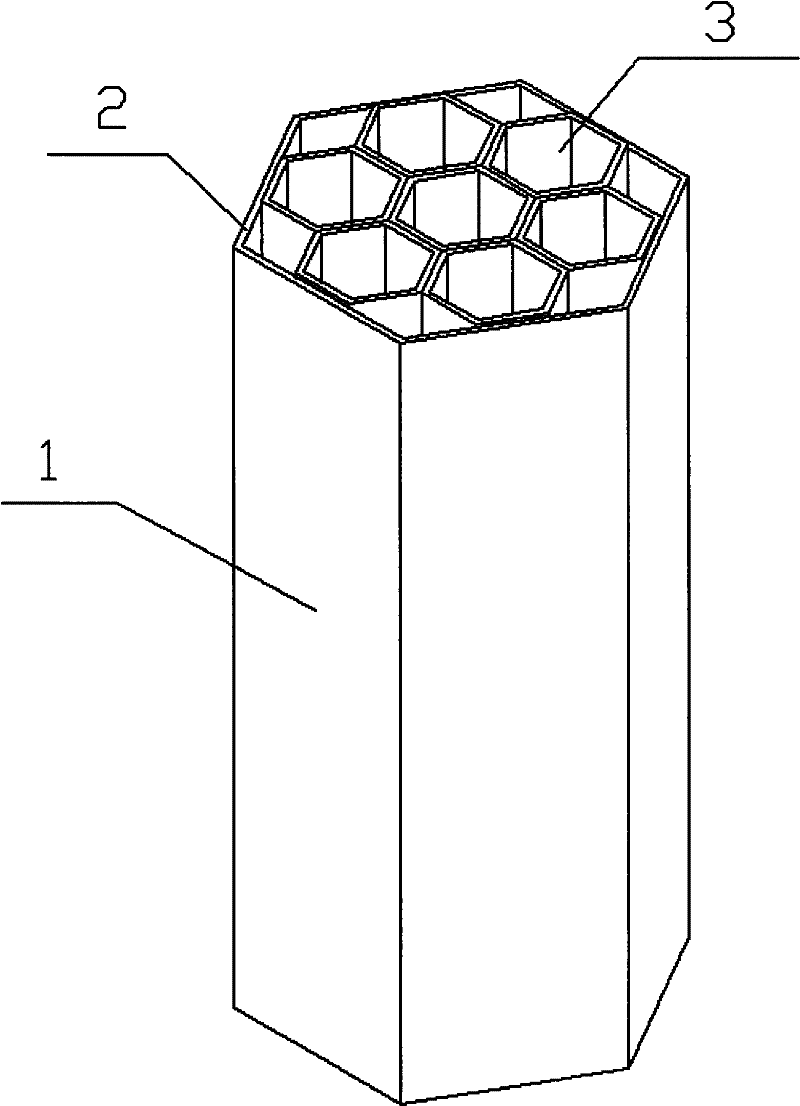

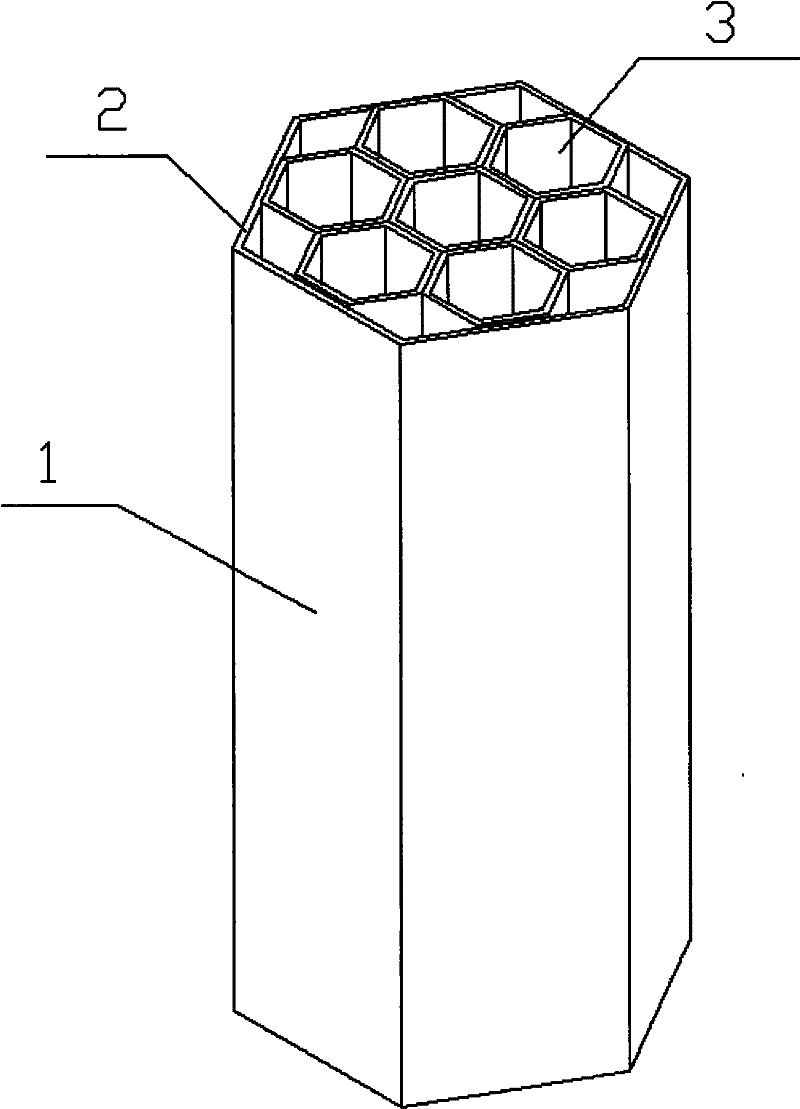

[0017] Such as figure 1 As shown, the present invention provides a stainless steel heald automatic cleaning and grinding device, the grinding device includes a heald grinding bucket 1, and the grinding bucket is a large grinding outer cylinder 2 with a plurality of small grinding inner cylinders installed 3. The grinding outer cylinder is a hexagonal empty barrel. The small grinding inner cylinder is a hexagonal empty barrel, which is evenly arranged in the outer grinding cylinder in a honeycomb shape. formed as figure 1 The shown large grinding outer cylinder is evenly arranged with 7 small grinding inner cylinder structures arranged in a honeycomb shape.

[0018] For the deburring of finished healds, ordinary hexagonal barrels are used. Due to the relatively large inner diameter of the ordinary hexagonal empty barrels, the healds will bend and twist during the rolling grinding process, which seriously affects the output and quality of the product. In the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com