An online deburring machine based on high-voltage ceramic capacitor ceramic dielectric chip

A high-voltage ceramic and burr removal technology, which is applied in capacitors, capacitor manufacturing, and machine tools suitable for grinding workpiece edges, etc., can solve problems such as low production efficiency, missing chamfers, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

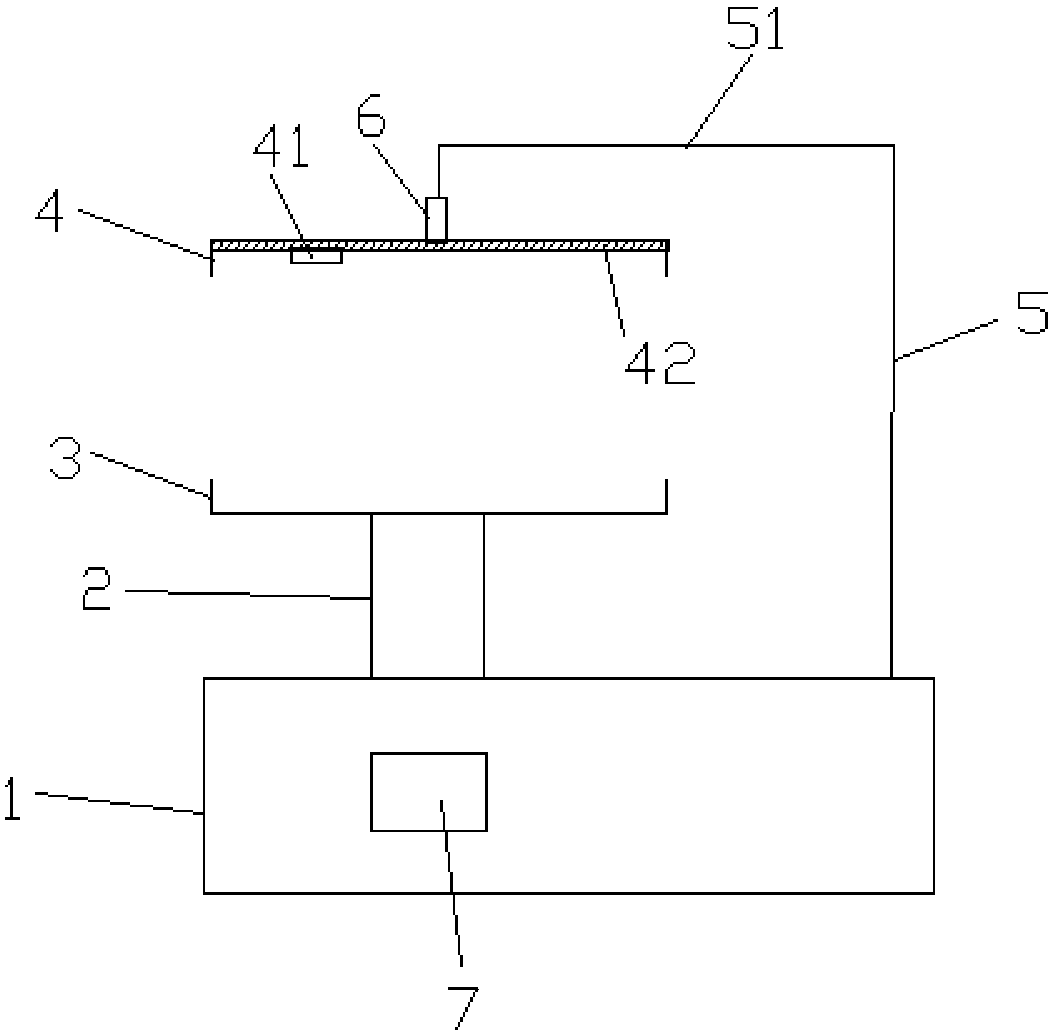

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

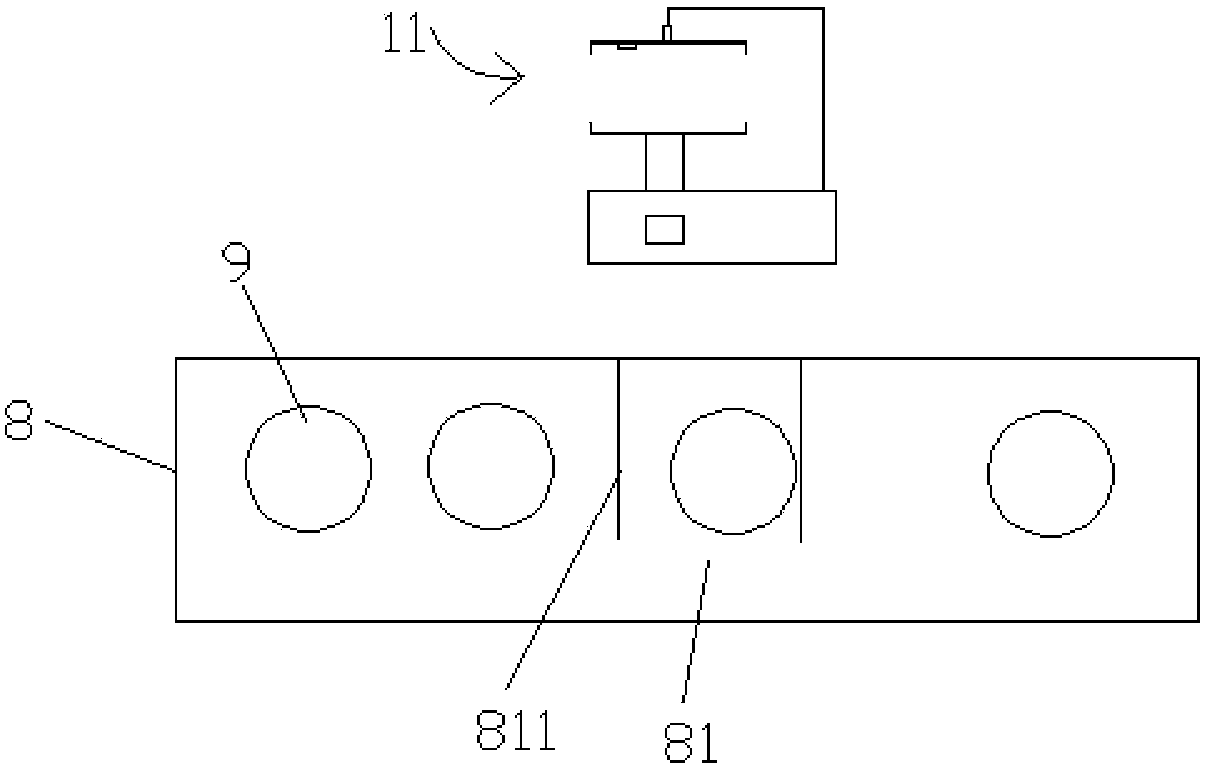

[0018] Such as figure 1 and figure 2 As shown, an online deburring machine based on a high-voltage ceramic capacitor ceramic dielectric chip, including a base 1, a rotating shaft 2, a lower die 3, an upper die 4, a pressure sensor 41, an electromagnet 42, a support rod 5, and a cross bar 51 , rotating bearing 6, control panel 7, automatic transmission line 8, burr removal station 81, partition 811, porcelain dielectric chip 9 and burr removal device 11 and other main technical features.

[0019] An online deburring machine based on a high-voltage ceramic capacitor ceramic dielectric chip, including an automatic transmission line and a deburring device.

[0020] Such as figure 1 As shown, there is a deburring station on the automatic transmission line, and the deburring station includes two partitions, each partition can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com