Swing regulation mechanism of gear end surface profiling chamfering machine

A technology of adjusting mechanism and chamfering machine, which is used in gear cutting machines, components with teeth, gear teeth manufacturing devices, etc., can solve the limitation of contact reset response speed, the impact of workpiece tooth surface is increased, and the rotation speed cannot be too fast, etc. problems, to achieve the effect of high chamfering quality, reducing rigid impact, and precise control of chamfering size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

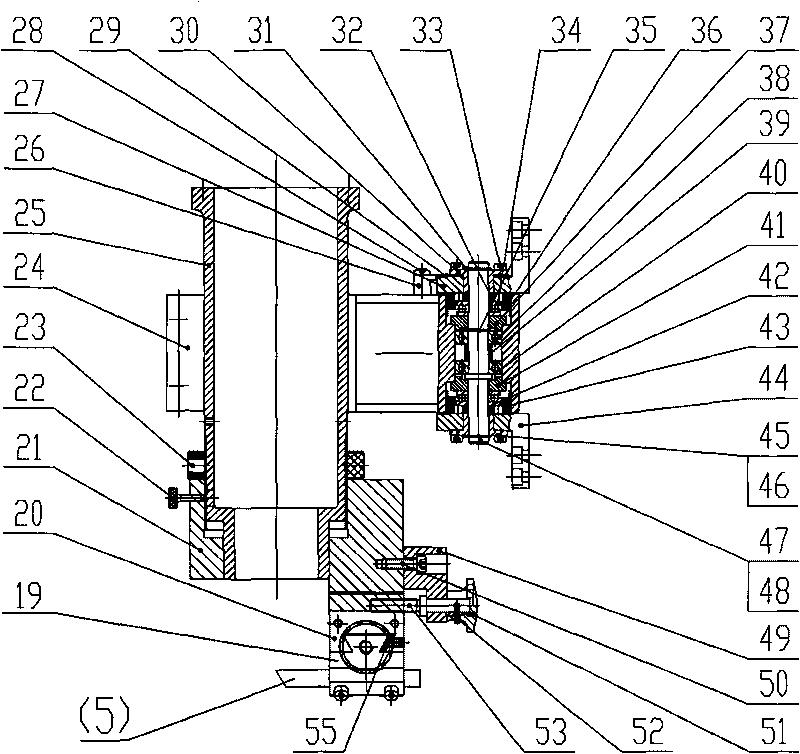

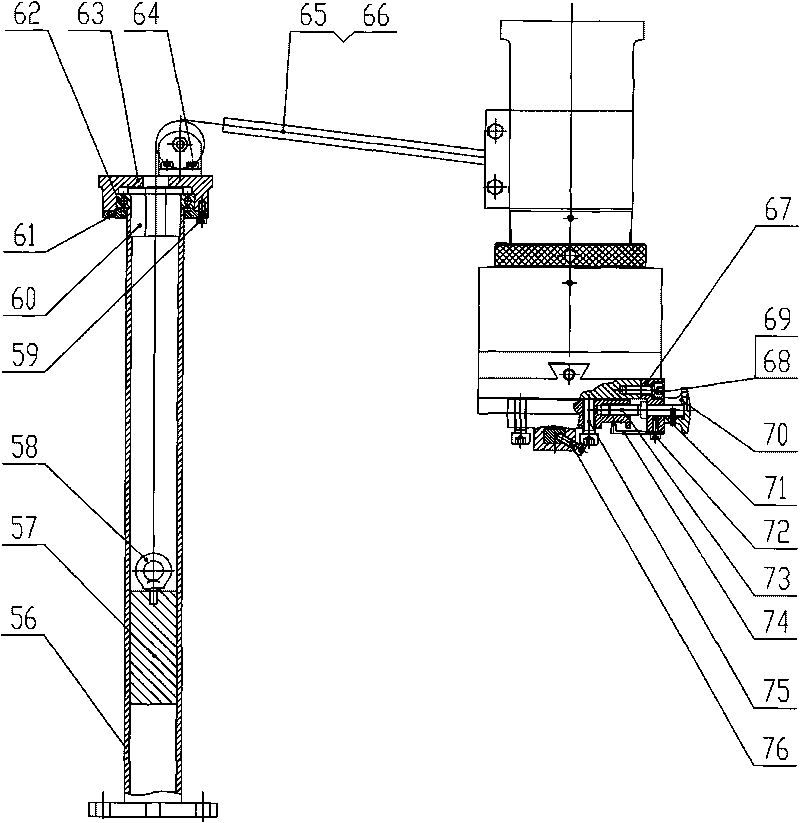

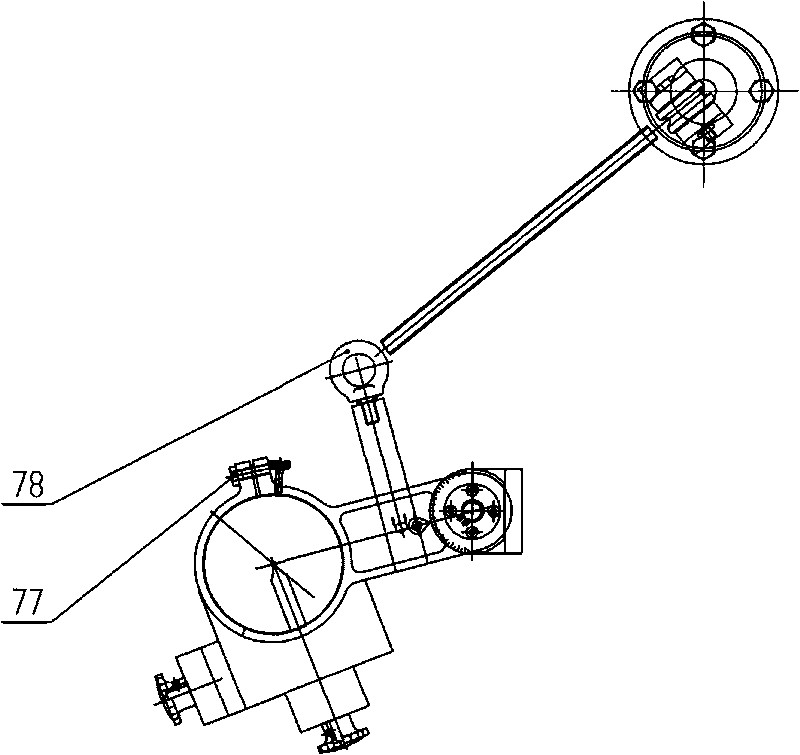

[0015] As shown in the figure: the present invention mainly includes a sliding seat 19, a middle sliding seat 20, an upper sliding seat 21, a positioning screw 22, a positioning nut 23, a connecting rod 24, a power head fixing seat 25, a pointer 26, an upper fixing plate 27, a disk Head screw 28, dial 29, upper bearing cap 30, retaining spring 31, spacer 32, hexagon socket head screw 33, bearing 34, retaining spring 35, upper threaded coupling sleeve 36, upper bearing cap 37, bearing 38, spacer 39 , bearing 40, lower bearing cover 41, bearing 42, lower threaded coupling sleeve 43, lower fixing plate 44, lower bearing cover 45, hexagon socket screw 46, pin shaft 47, snap spring 48, left and right adjustment screw mounting seat 49, inner Hexagon screw 50, embossed handle 51, elastic cylindrical pin 52, left and right adjustment screw 53, hexagon socket set screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com