Power unit device of gear-face profiling chamfering device

A gear end and power head technology, which is applied to gear tooth manufacturing devices, driving devices, mechanical equipment, etc., can solve the problems of difficult control of the size of chamfers, complicated transmission and indexing mechanisms, and inability to achieve full-tooth chamfers. The size of the chamfer can be precisely controlled, the customer's use cost is low, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

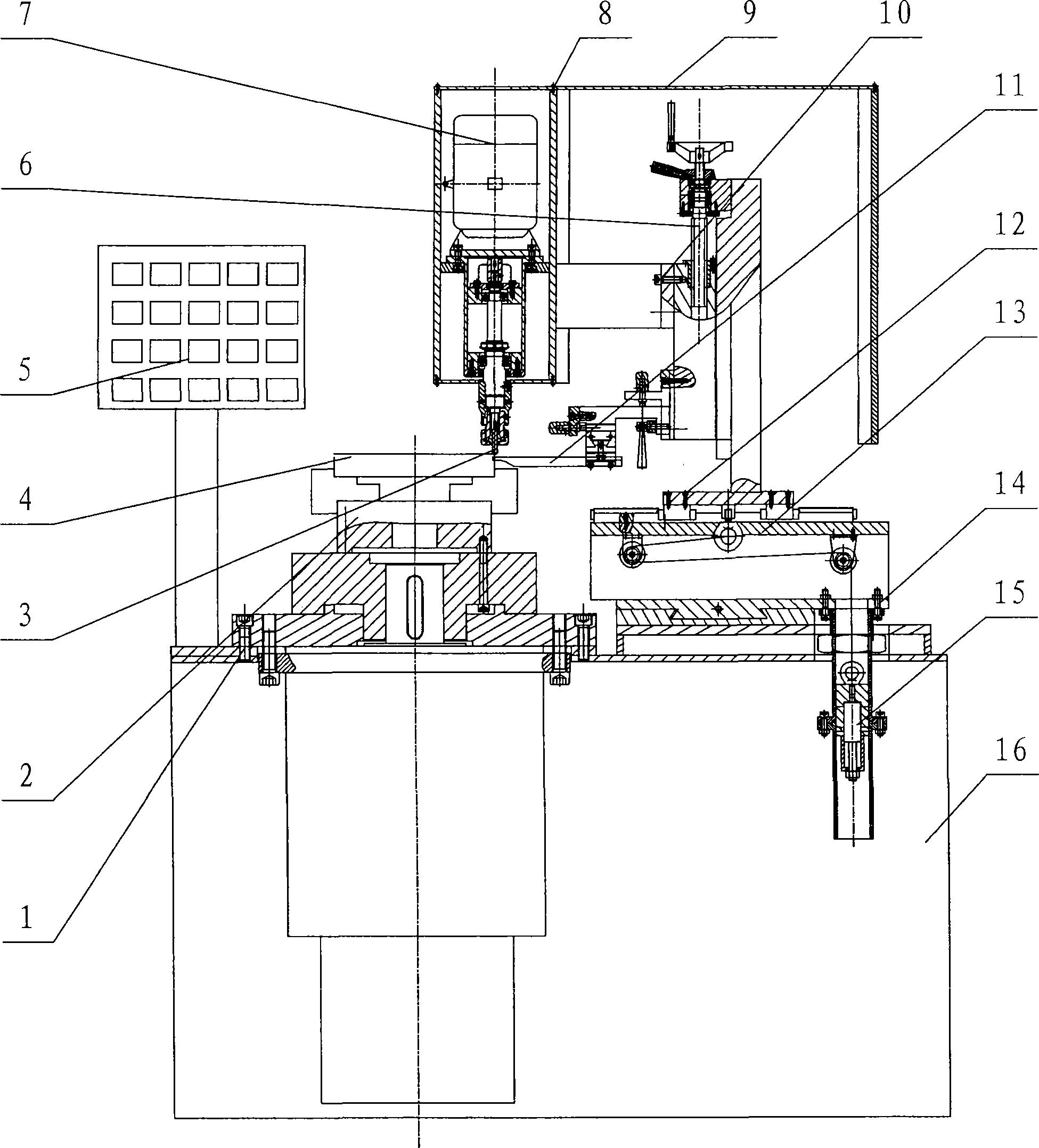

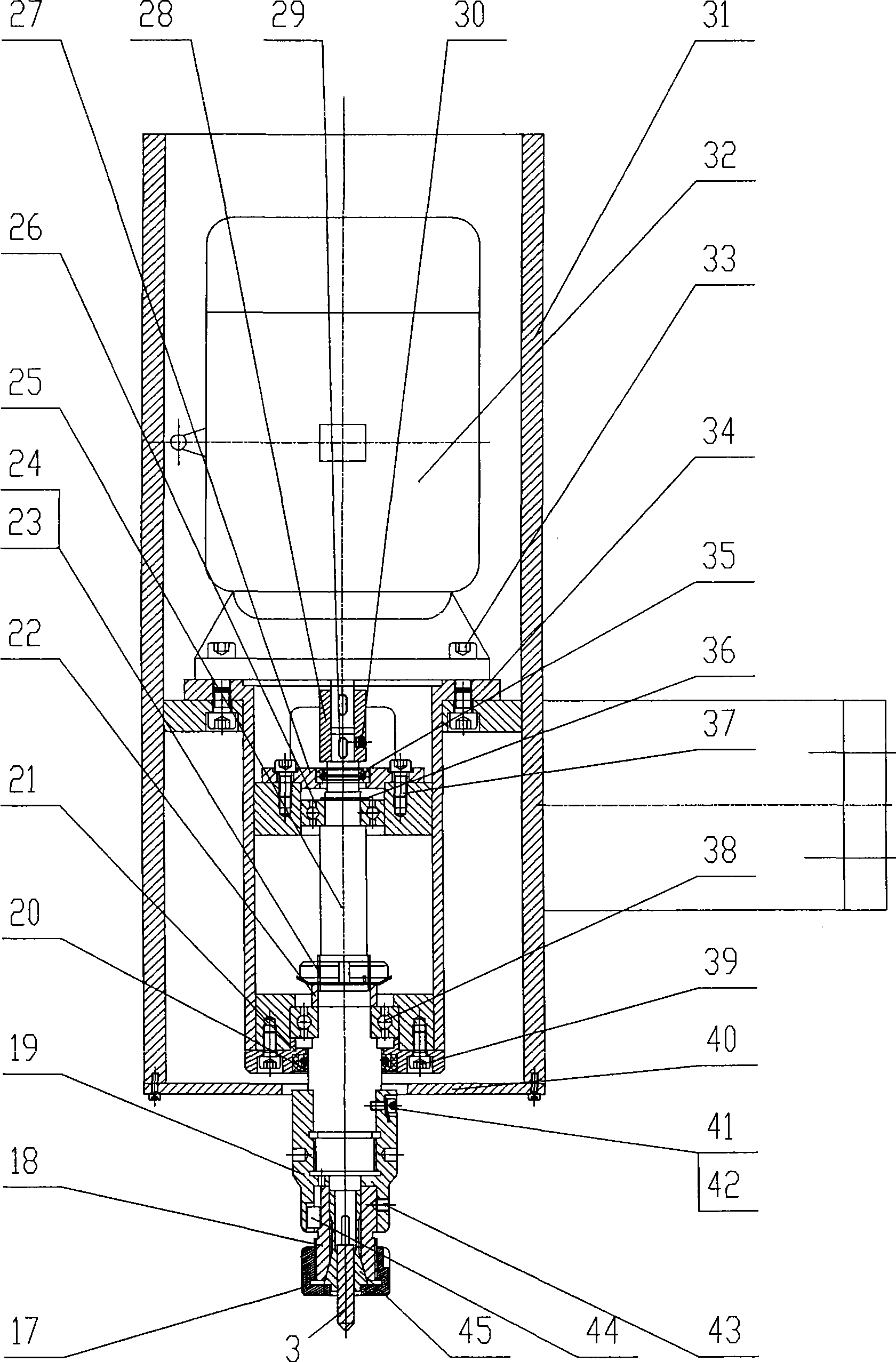

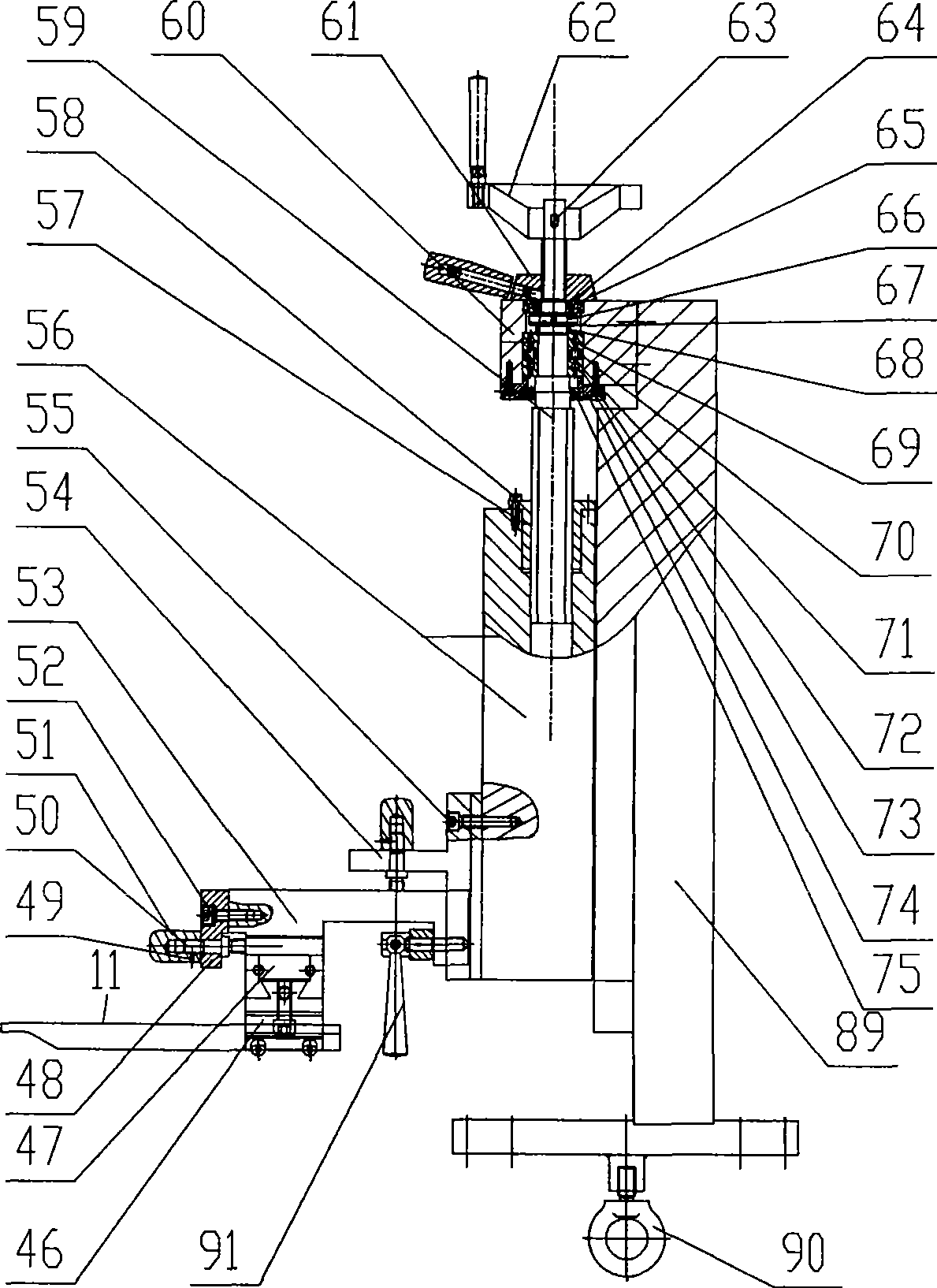

[0020] 1. Screw, 2. Fixture device, 3. Tool, 4. Workpiece (gear), 5. Control panel, 6. Adjusting device, 7. Power head device, 8. Screw, 9. Cover, 10. Screw, 11 , Profiled contact, 12, screw, 13, linear guide pair, 14, screw, 15, constant force device, 16, bed, 17, lock nut, 18, transition sleeve, 19, coupling sleeve, 20, seal Ring, 21, lower bearing cover, 22, spacer, 23, stop washer, 24, round nut, 25, shaft, 26, bearing, 27, upper bearing cover, 28, sleeve coupling, 29 , flat key, 30, set pin, 31, support, 32, motor, 33, screw, 34, sleeve, 35, sealing ring, 36, circlip for shaft, 37, screw, 38, bearing, 39, Screw, 40, lower cover of protective cover, 41, screw, 42, washer, 43, set screw, 44, flat key, 45, collet, 46, Y-direction sliding seat, 47, X-direction sliding seat, 48 , middle fixing plate, 49, pin, 50, first screw rod, 51, first scale knurled nut, 52, screw, 53, Z-direction sliding seat, 54, upper fixing plate, 55, screw, 56, first Slider, 57, nut, 58, screw, 59, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com