Apparatus and method for deburring ball head by chamfering

A deburring and ball head technology, applied in the field of ball head chamfering deburring devices, can solve the problems of environmental pollution, high processing cost, unclean burr removal, etc., and achieves simple structure of the process device, reduced processing cost, and chamfering effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

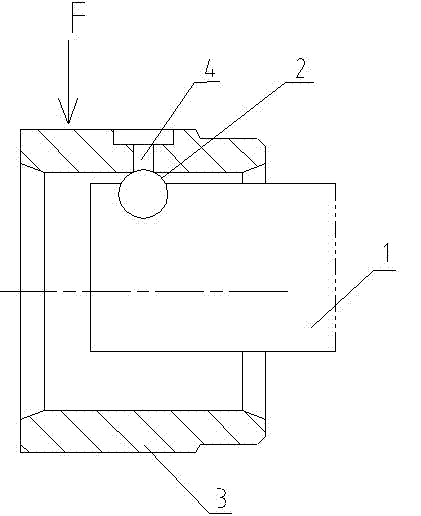

[0024] See figure 1 , The present invention relates to a ball-end chamfering and deburring device. The device includes a support 1 fixed on the worktable of a machine tool. The support 1 is provided with a cambered bump 2, preferably, A ball head is embedded on the surface of the support 1, and a part of the ball head is exposed to the support 1 to form a spherical convex convex;

[0025] The following process steps are used when chamfering:

[0026] Step 1. Put the workpiece 3 to be processed on the support 1 first;

[0027] Step 2. The arc surface of the arcuate bump 2 located in the pipe hole of the workpiece 3 is close to the hole wall of the burr hole 4. At the same time, the center of the arcuate bump 2 is located on the central axis of the burr hole 4, and the arc The diameter of the surface bump 2 is larger than the diameter of the burr hole 4;

[0028] Step 3: Apply a pressure F on the outer tube wall of the workpiece 3, so that the contact part of the burr hole 4 of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com