Deburring device capable of adjusting chamfering size

A technology for de-flashing and chamfering, which is applied in the field of de-flashing and burr equipment, can solve the problems that tools and equipment are difficult to meet the control requirements of chamfering, difficult to control the size of chamfering, and the size of chamfering is different, so as to achieve the reuse rate. , The effect of adjusting the size of the chamfer is simple and accurate, and the chamfering process is smooth and labor-saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

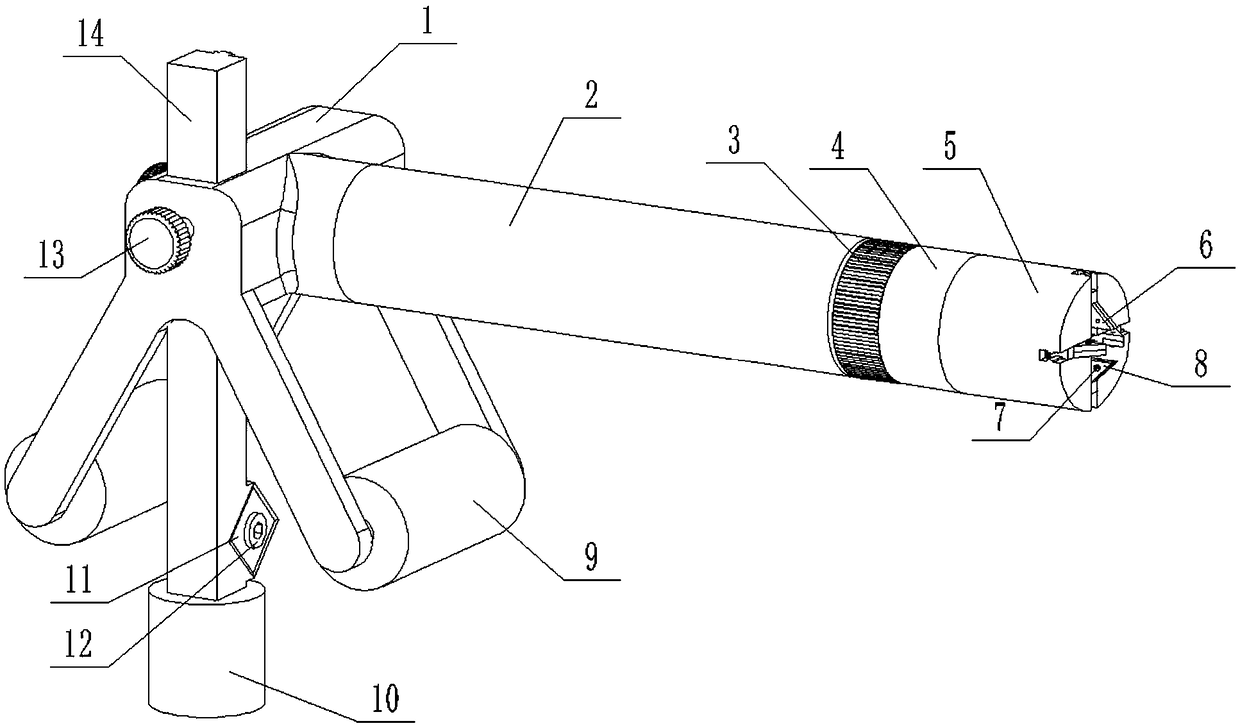

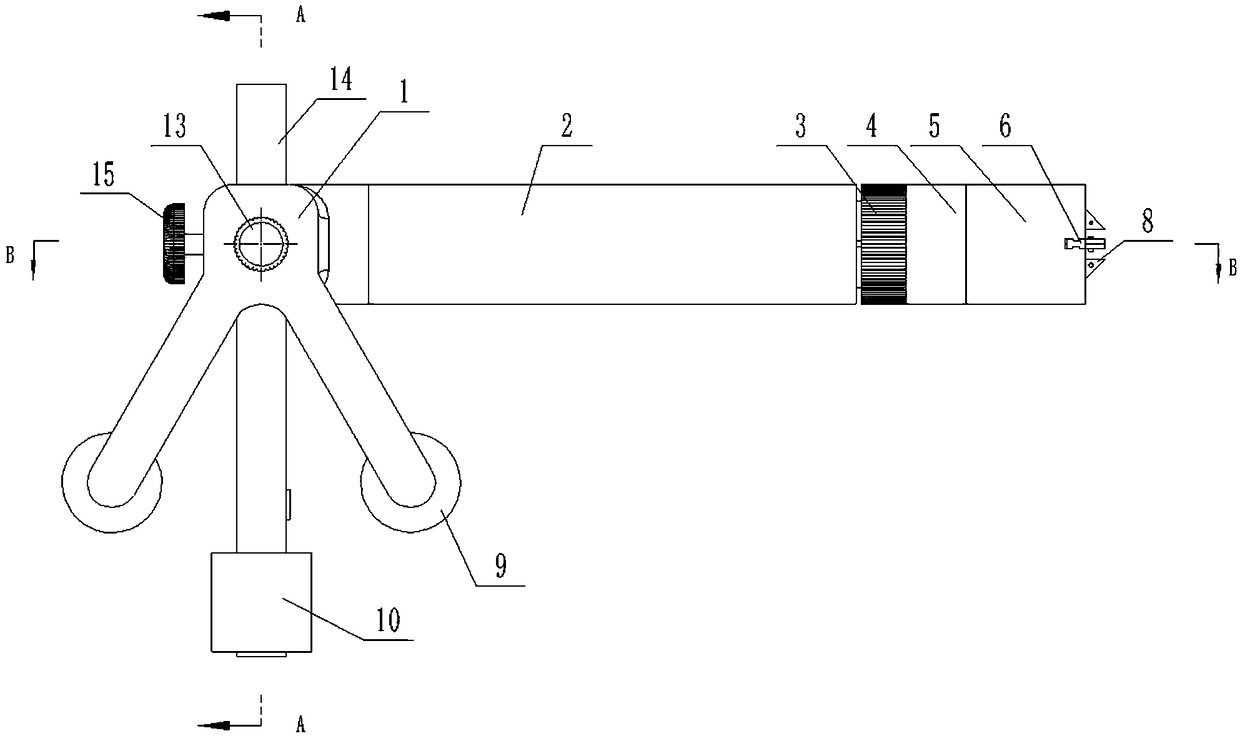

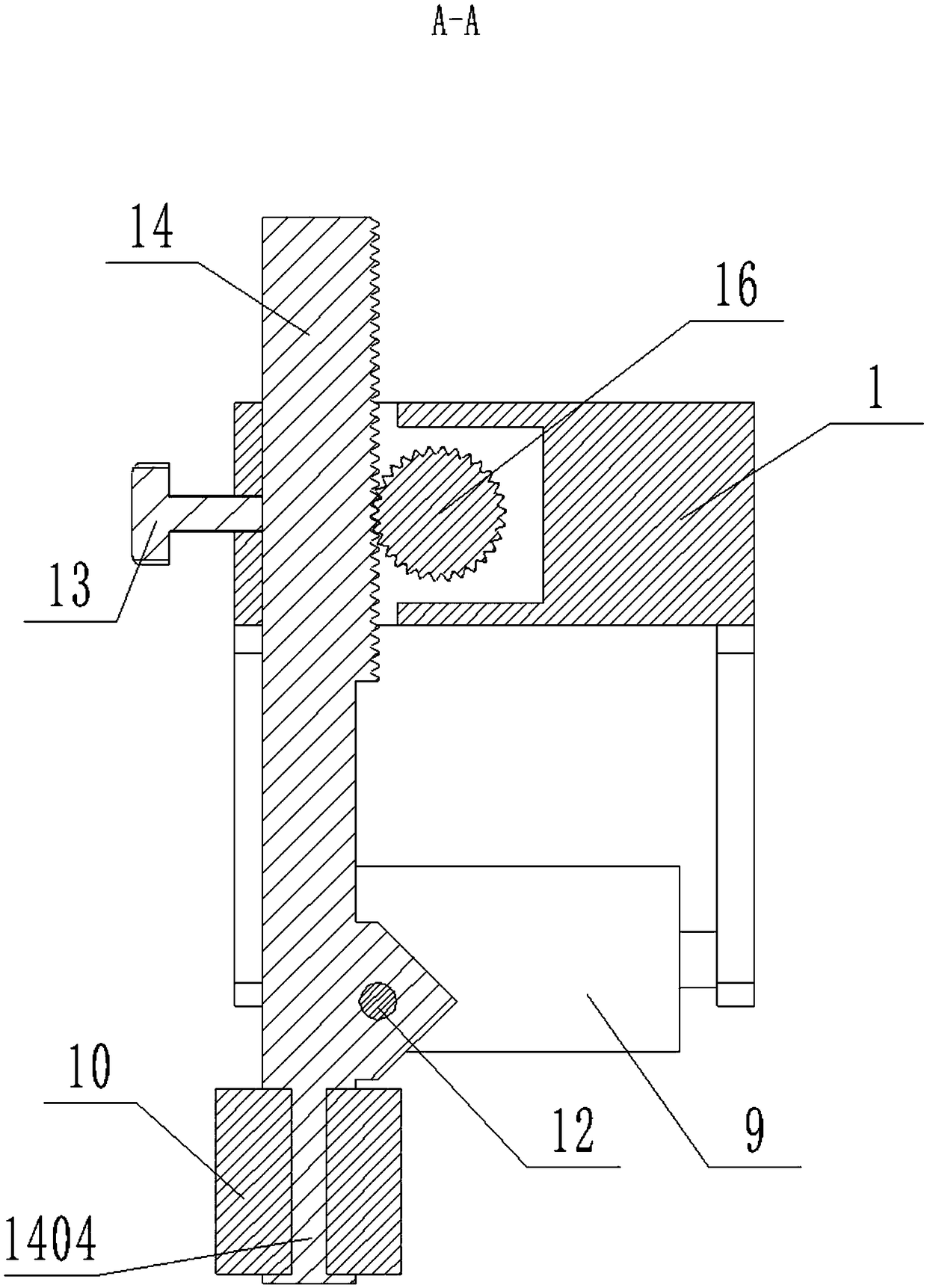

[0031] as attached figure 1 to attach Figure 9 Shown:

[0032] The present invention provides a deburring device capable of adjusting the chamfering size, including a frame body 1, a dovetail groove 0101, a handle 2, a connecting thread 0201, a locking ring 3, a small hole chamfering adjustment head 4, and a locking table 0401 , taper thread 040101, locking deformation groove 040102, small hole chamfering adjustment ring 0402, flat rectangular thread 0403, chamfering end block 5, guide groove 0501, sliding block 6, flat thread groove 0601, small hole chamfering blade fixing table 0602, sliding groove block 0603, small hole chamfering blade fixing screw 7, small hole chamfering blade 8, horizontal roller 9, vertical roller 10, large surface chamfering blade 11, large surface chamfering blade fixing screw 12, locking screw 13, Adjusting rod 14, dovetail block 1401, rack 1402, blade fixing table 1403, vertical roller connecting shaft 1404, adjusting knob 15, and gear 16; each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com