Wafer chamfering process

A round wafer and chamfering technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, metal processing equipment, etc., can solve the problems that the edge does not meet the standard requirements, the friction time of chamfering is long, and it shrinks when it becomes cold, so as to improve the chamfering. Angle effect, reduce the magnitude of thermal expansion and contraction, and reduce the volume of the part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

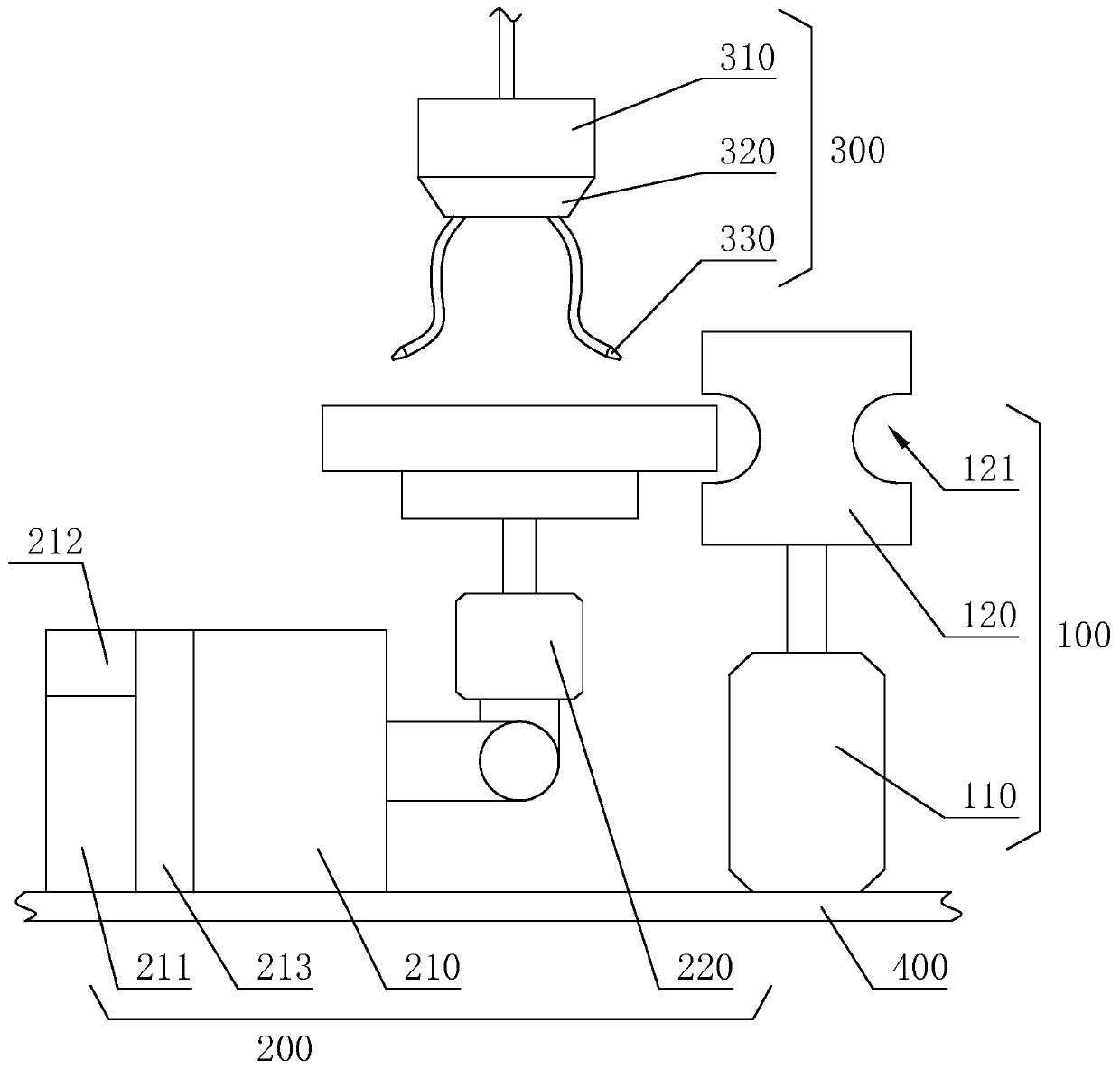

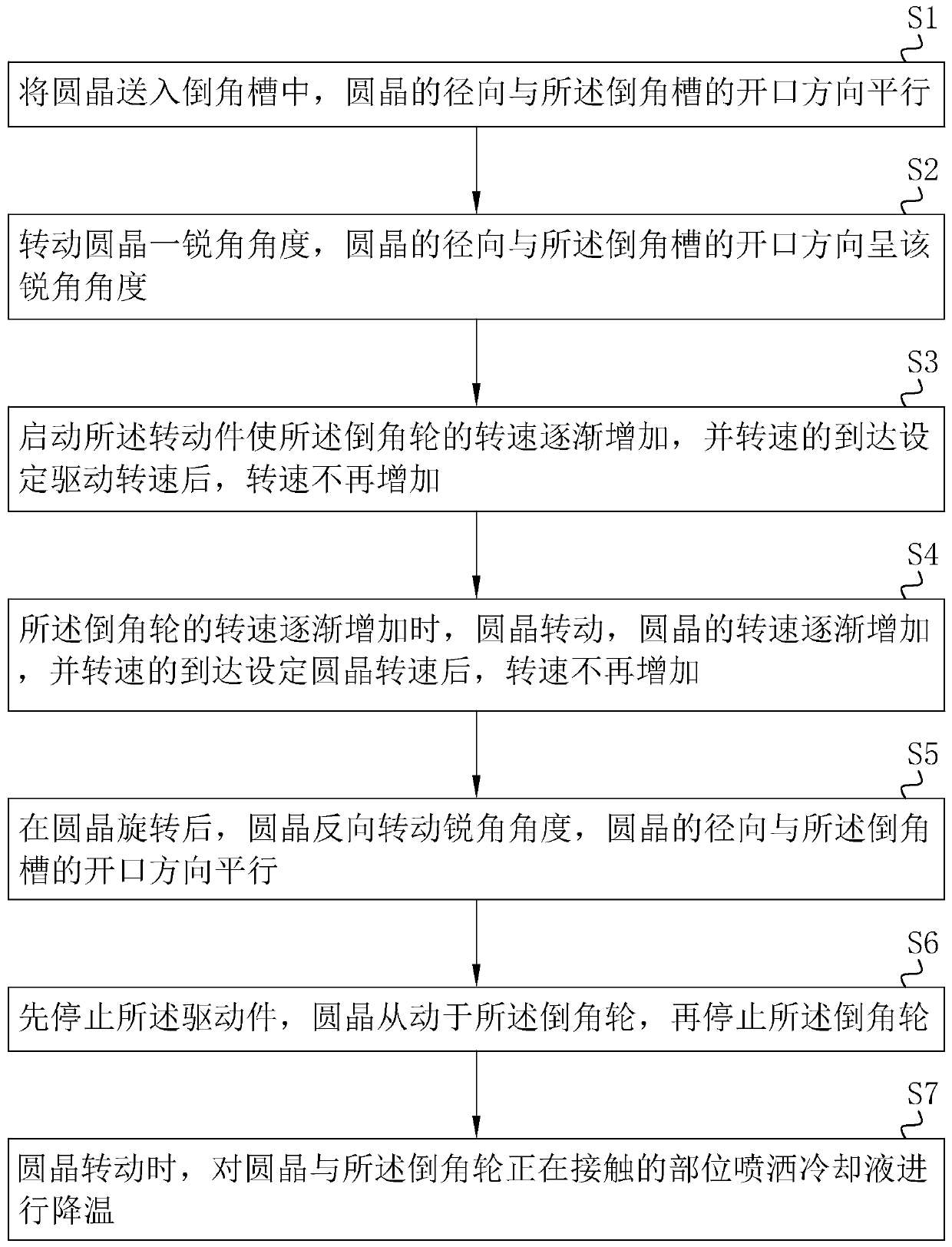

[0034] A wafer chamfering process, such as figure 1 As shown, based on the wafer chamfering device 100 for chamfering the wafer, the fixing jig 200 for installing the wafer, and the cooling assembly 300 for cooling the wafer chamfering device 100 and the wafer, the wafer chamfering The device 100 , the fixing fixture 200 and the cooling assembly 300 are fixed on the workbench 400 through bolt connection or welding, and the cooling assembly 300 is fixed on the workbench 400 through suspender welding.

[0035] The wafer chamfering device 100 includes a rotating part 110 fixed on the upper end of the workbench 400 by bolting or welding. The rotating part 110 can be a motor connected to the mains. A chamfering wheel 120 is connected, the axis line of the chamfering wheel 120 is vertically arranged, and the chamfering wheel 120 can be a grinding wheel. The side of the chamfering wheel 120 is provided with an arc-shaped chamfering groove 121, and the opening direction of the chamfe...

Embodiment 2

[0048] A wafer chamfering process, the difference from Embodiment 1 is that the rotation direction of the wafer is the same as the rotation direction of the chamfering wheel 120, and the rotation speed of the wafer is lower than the rotation speed of the chamfering wheel 120. When chamfering, the wafer The direction of rotation of the parts where the chamfering wheels 120 contact each other is opposite, so that the speed of the wafer chamfering process can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com