Quick chamfering device and method for automobile ornament trimmings

A technology of automobile trim and chamfering device, which is applied to household components, other home appliances, home appliances, etc., can solve the problems of easy occurrence of burrs, corners, and poor use effect of automobile trims, and achieves good effects and use effects. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

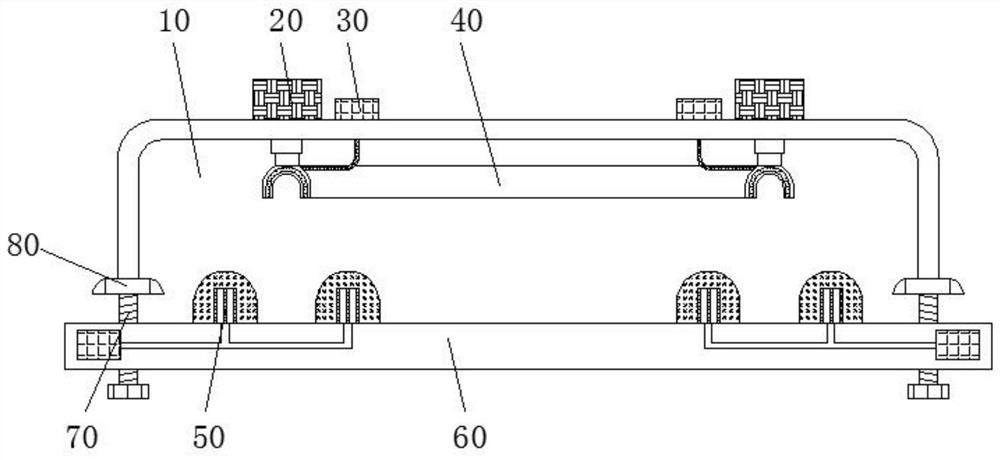

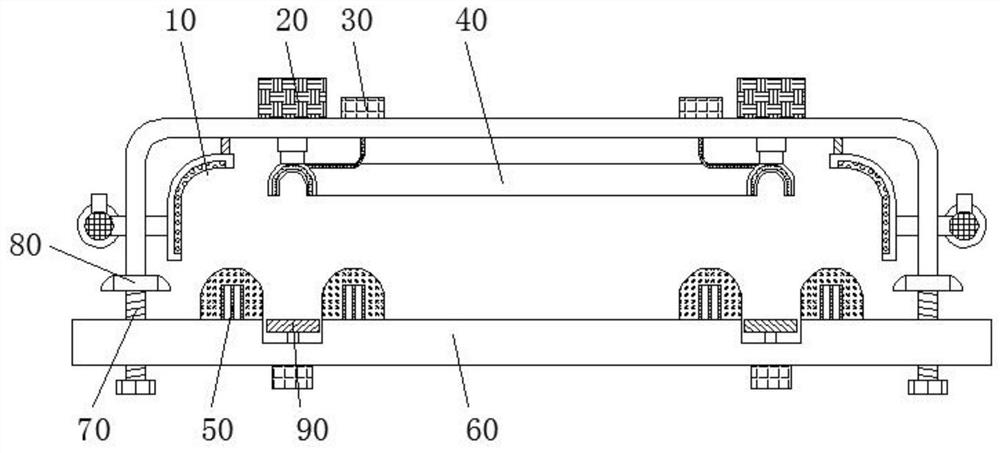

[0030] like Figure 1-2 As shown, a flash chamfering device for automotive trims described in this embodiment includes a chamfering processing chamber 10, a hydraulic rod 20, a first power storage device 30, a U-shaped heating plate 40, a heating mechanism 50, and a fixed base 60. Adjusting bolt 70 and sealing plate 80, the fixed base 60 is connected to the chamfering processing bin 10 through the adjusting bolt 70, the bottom of the chamfering processing bin 10 is provided with a sealing plate 80, the chamfering processing bin 10 There is a U-shaped heating plate 40 inside, and the top of the chamfering processing bin 10 is provided with a hydraulic rod 20 that drives the U-shaped heating plate 40 to move up and down. The top of the chamfering processing bin 10 is provided with a U-shaped heating plate 40 The first power accumulator 30 for supplying power, the fixed base 60 is provided with a heating mechanism 50 sandwiching an automobile trim.

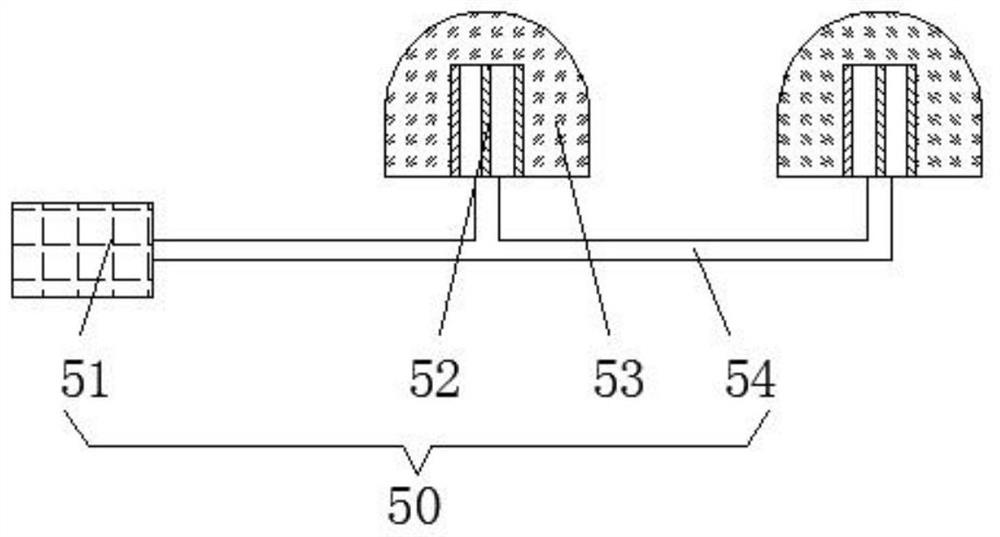

[0031] A heating mechanism 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com