Chamfering machine for wind turbine blade lining foam board

A technology for wind turbines and foam boards, which is applied in metal processing and other directions, can solve the problems of inability to adjust the chamfering angle and the amount of chamfering, not suitable for foam boards, and high labor intensity, and achieves good chamfering effect, simple structure, and high labor intensity. Adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

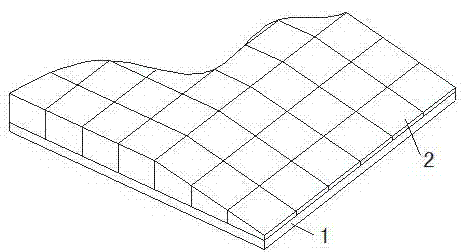

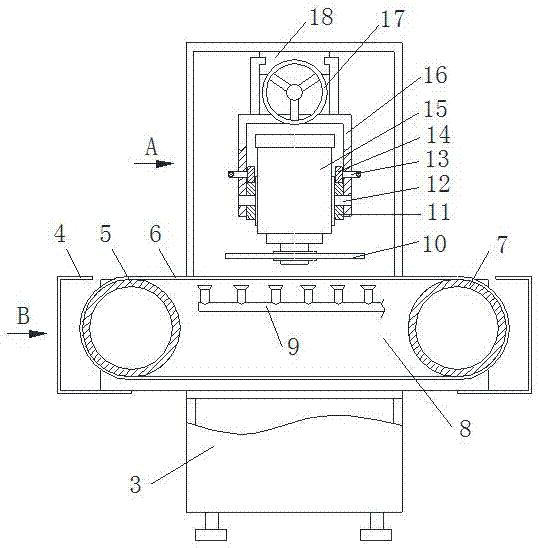

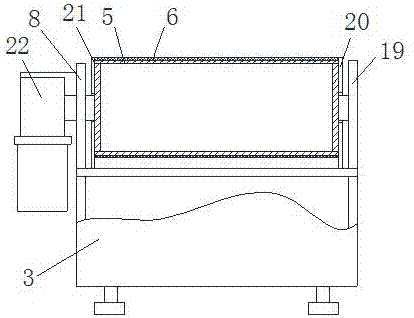

[0021] Such as figure 2 , image 3 with Figure 4 As shown, the chamfering machine for foam boards lining the wind turbine blades of the present invention includes a base, a conveying mechanism and a chamfering mechanism, both the conveying mechanism and the chamfering mechanism are installed on the base, and the conveying mechanism is in front of the chamfering mechanism. The base includes a chassis 3 and a front wall panel 19 and a rear wall panel 8 respectively arranged on the front and rear sides of the chassis 3 .

[0022] see figure 2 with image 3 , The conveying mechanism includes a driving roller 5, a driven roller 7, a conveyor belt 6 and a transmission device. The driving roller 5 and the driven roller 7 are installed on the left and right sides of the front wallboard 19 and the rear wallboard 8 respectively, and a conveyor belt 6 is connected between the driving roller 5 and the driven roller 7 . Shields 4 are provided on the bottom frame 3 on the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com