Helical bevel gear tooth crest edge chamfering method based on entity contact analysis

A technology of spiral bevel gear and contact analysis, applied in the direction of gear teeth, belts/chains/gears, components with teeth, etc. The effect of low production preparation cost, optimized grinding wheel taper angle and high machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

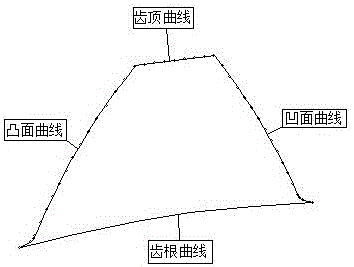

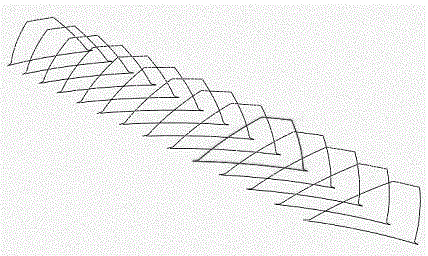

[0054] The invention first establishes the solid model of the spiral bevel gear and the conical grinding wheel, and then uses the solid contact analysis method to determine the spatial movement relationship between the grinding wheel and the gear based on the principle that the grinding wheel cuts into the maximum depth in the direction perpendicular to the face cone. Complete chamfering simulation processing based on the spatial motion relationship. Through the analysis of the chamfering effect of the solid model after the simulation processing, the optimized cone angle of the grinding wheel is determined, so that the chamfering effect is optimal. According to the selected general five-axis machining center structure, calculate the X, Y, Z, A, and B axis motion parameters, and finally output the chamfering CNC code; the details are as follows:

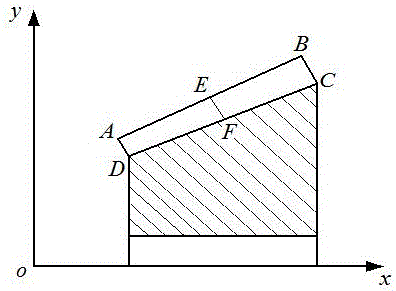

[0055] The profile of the shaft section of the gear is as figure 1 In the figure, x is the axial direction of the gear, and y is the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com