Edge chamfering device for furniture production

A chamfering device and edge technology, which is applied in the field of edge chamfering devices for furniture production, can solve the problems of inconvenient replacement of chamfering wheels and inability to perform chamfering, and achieve better chamfering effect, less shaking, and improved use effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

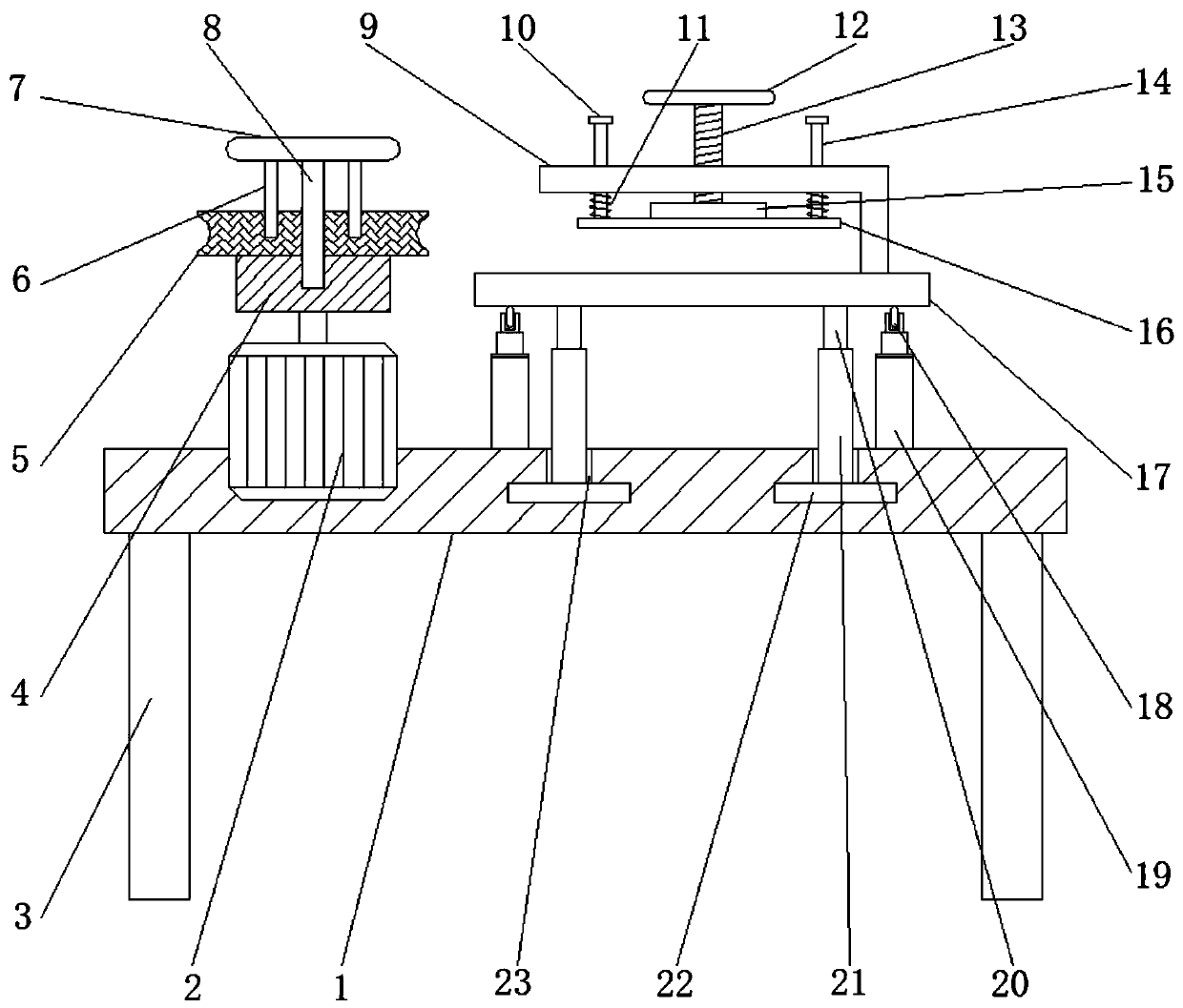

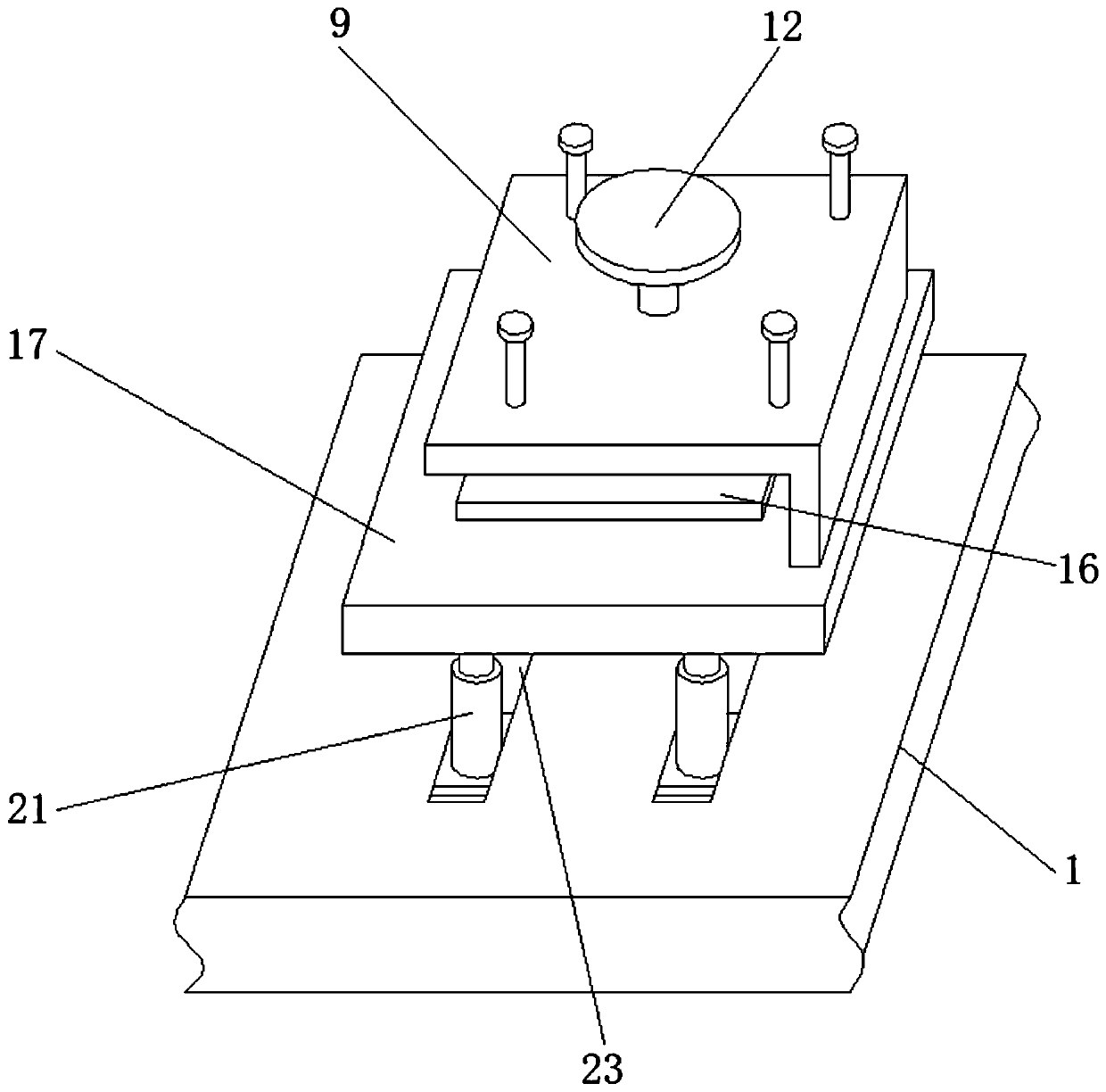

[0027] refer to Figure 1-2 , an edge chamfering device for furniture production, including a workbench 1, a mounting groove is opened on the top outer wall of the workbench 1, and a motor 2 is connected to the inner wall of the mounting groove through bolts, and a turntable 4 is arranged at one end of the output shaft of the motor 2 , and the top outer wall of the turntable 4 has a threaded groove, the inner wall of the threaded groove is threadedly connected with a threaded rod 8, the outer wall of the threaded rod 8 is sleeved with a chamfering wheel 5, and the top outer wall of the threaded rod 8 is welded with an adjustment wheel 7, and the adjustment The bottom outer wall of the wheel 7 is welded with a limit rod 6, the top outer wall of the chamfering wheel 5 has a limit groove, and the inner wall of the limit groove is plugged with the outer wall of the limit rod 6, and the four corners of the top outer wall of the workbench 1 are all There is a T-shaped slot 23, and t...

Embodiment 2

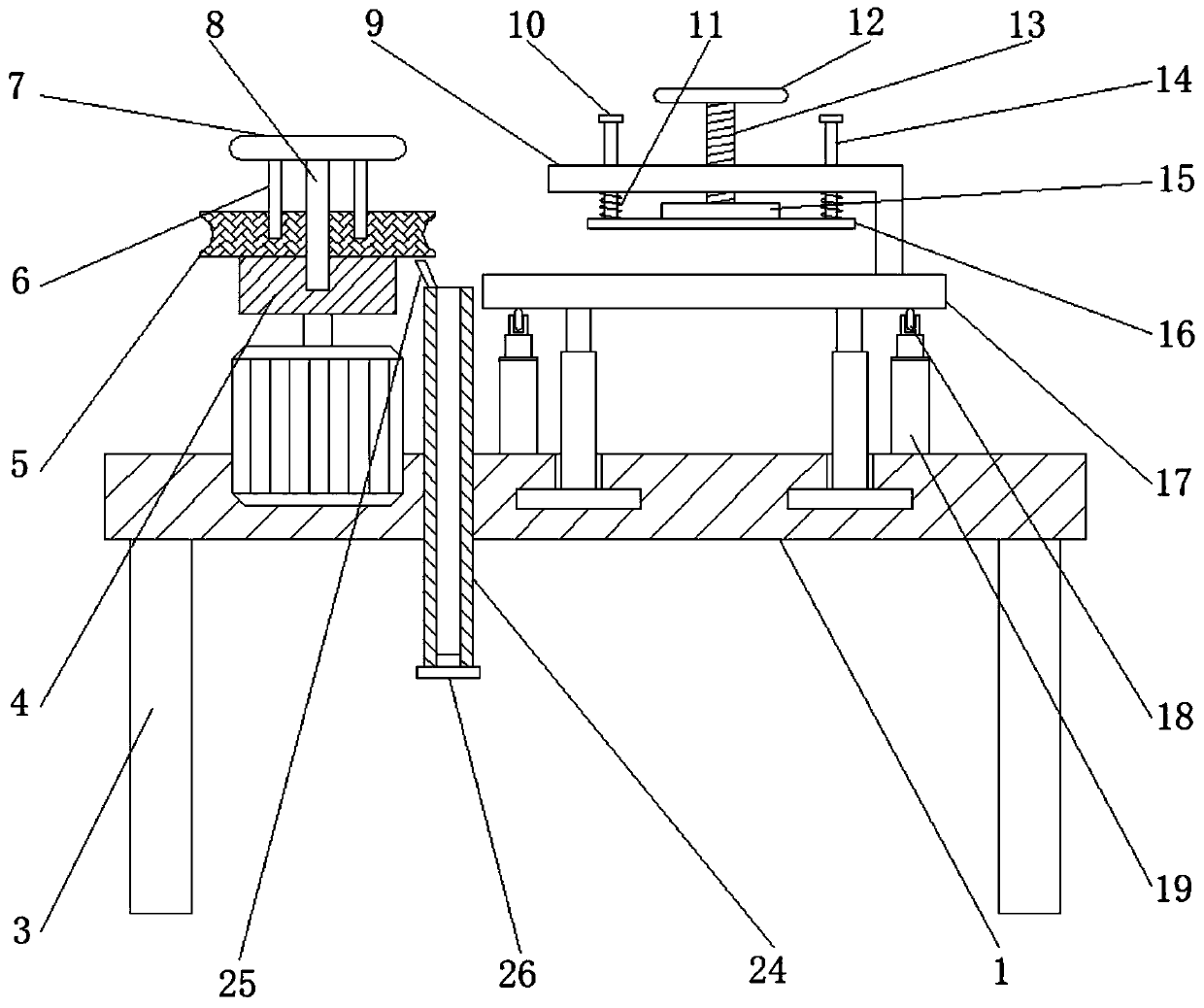

[0031] refer to image 3 , an edge chamfering device for furniture production. Compared with Embodiment 1, this embodiment also includes that the top outer wall of the workbench 1 is provided with an installation opening, and the inner wall of the installation opening is welded with a chip collecting bucket 24, and the chip collecting bucket The top outer wall of 24 is welded with a baffle plate 25 , and the bottom outer wall of the dust collection bucket 24 is clipped with a cover plate 26 .

[0032] Working principle: when in use, the chamfering chips will fall into the chip collecting bucket 24, and the baffle plate 25 on the chip collecting bucket 24 can well block the wood chips into the chip collecting bucket 24, when collected to a certain extent Finally, you can directly open the cover plate 26 to collect the sawdust, effectively avoiding the pollution of the workbench 1 by the sawdust produced by chamfering, and the use effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com