Weighing and batching system

A batching system and material hole technology, which is applied in the field of material batching system, can solve the problems of low weighing accuracy and long weighing time, and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

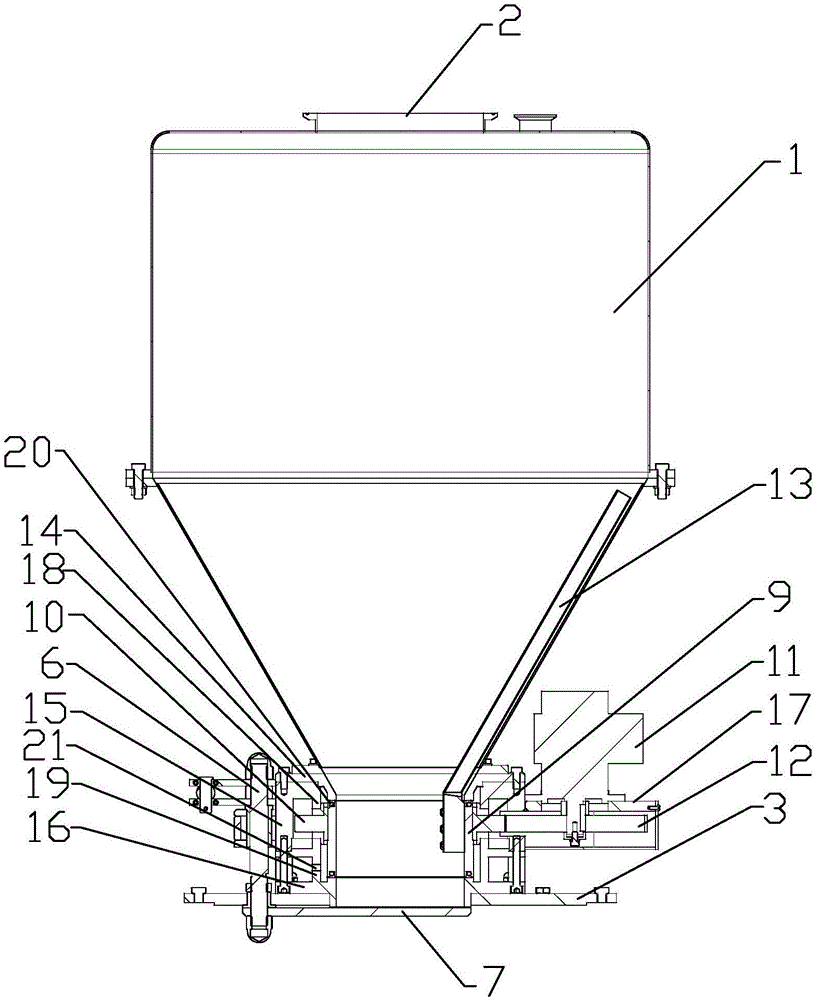

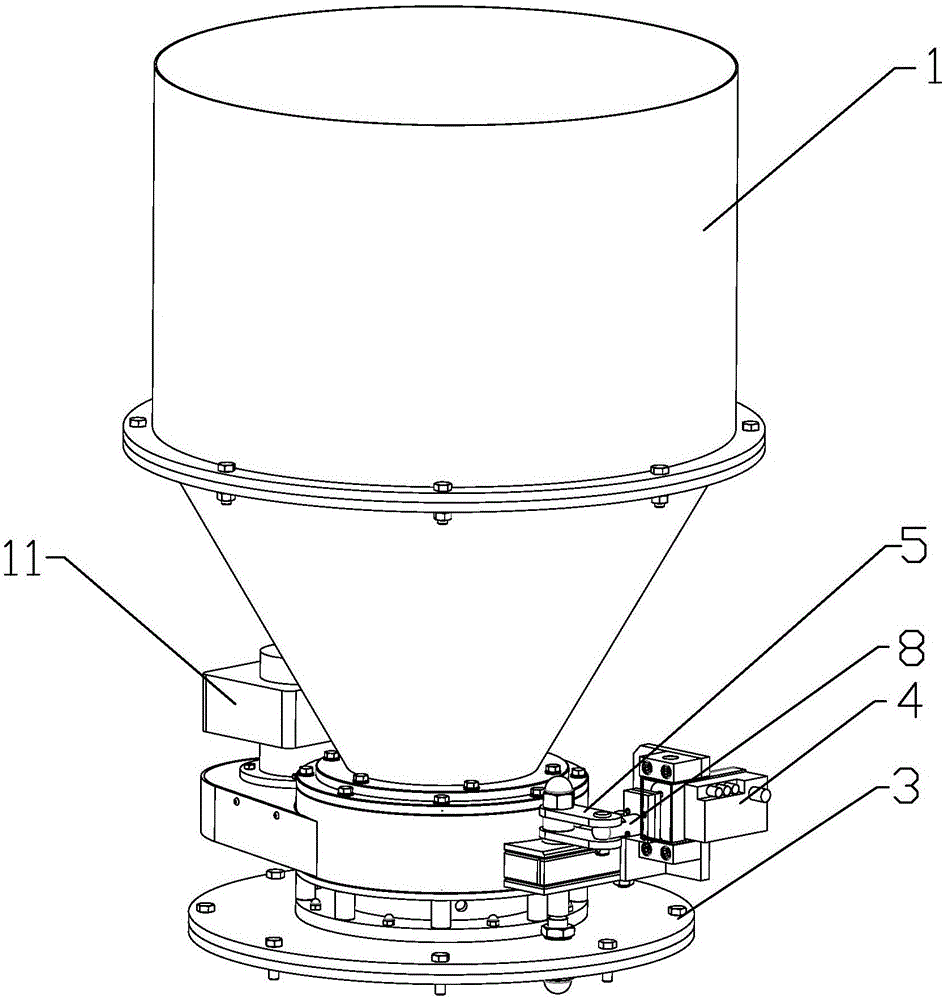

[0031] Specific implementation mode one: combine figure 1 , figure 2 and Figure 4 Describe this embodiment, this embodiment includes a batching device, the batching device includes a material storage tank 1, the upper part of the material storage tank 1 is cylindrical, and the lower part of the material storage tank 1 is cone-shaped, which is convenient for the material to be placed inside it. drop, the top of the storage tank 1 is provided with a feed port 2, and the bottom of the storage tank 1 is provided with a discharge port, and it also includes a flange 3, a connecting rod 5, a rotating shaft 6, a discharge baffle 7 and Multi-point positioning cylinder 4, the flange 3 is provided with a discharge hole, the discharge port is connected with the discharge hole, the multi-point positioning cylinder 5 is installed above the flange 3, the The rotating shaft 6 vertically passes through the flange 3 and rotates with the flange 3. The top of the rotating shaft 6 is hinged to...

specific Embodiment approach 2

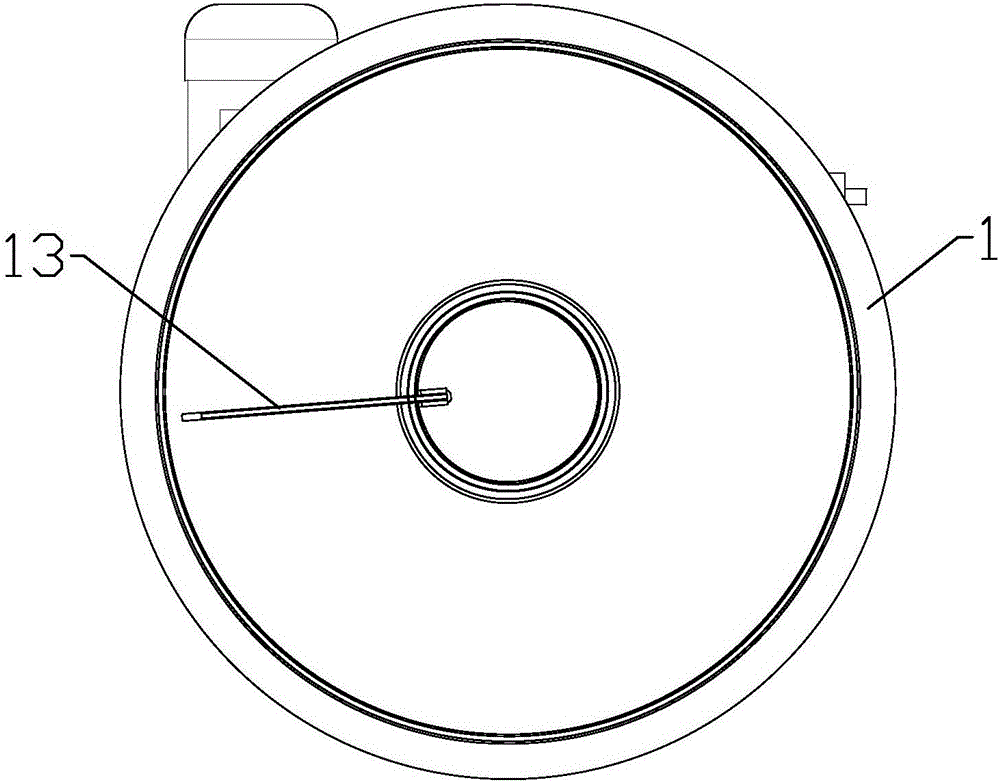

[0034] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, the batching device of this embodiment also includes a rotating sleeve 9, a driven gear 10, a motor 11, a driving gear 12 and a bridge breaking rod 13, and the rotating sleeve 9 is located between the storage tank 1 and the flange 3 There is an axial material channel between them, the upper end of the material channel communicates with the discharge port, the lower end of the material channel communicates with the discharge hole, and the driven gear 10 is coaxially and fixedly sleeved on the rotating shaft. The outer side of the cover 9, the bottom end of the bridge breaking rod 13 is fixedly connected to the inner wall of the rotating sleeve 9, and the bridge breaking rod 13 is inclined from the discharge port along the tapered inner wall of the storage tank 1 Stretch upwards in the described material storage tank 1, there is a gap between the bridge breaking rod 13 and t...

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1 Describe this embodiment, the dispensing device of this embodiment also includes a transition connector 14, a rotary sleeve shell 15, a rotary sleeve base 16 and a motor housing 17, the transition connector 14 is provided with an axial discharge hole, and the rotary The sleeve shell 15 and the rotating sleeve base 16 are hollow and the rotating sleeve base 16 is provided with an axial discharge channel. Up and down are sequentially coaxially fixed and sealed. The rotating sleeve shell 15 and the rotating sleeve base 16 form a hollow cavity. The rotating sleeve 9 and the driven gear 10 are located in the hollow cavity. The top of the rotating sleeve 9 is connected to the The bottom end of the transition connector 14 is docked and rotated, and the bottom end of the rotary sleeve 9 is docked and rotated with the top of the discharge channel of the rotary sleeve base 16. The discharge port, discharge hole, The materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com