Semi-automatic packaging machine for irregular bulk foods

A food packaging, semi-automatic technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of non-compliance with food hygiene requirements, difficulty in recruiting workers, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

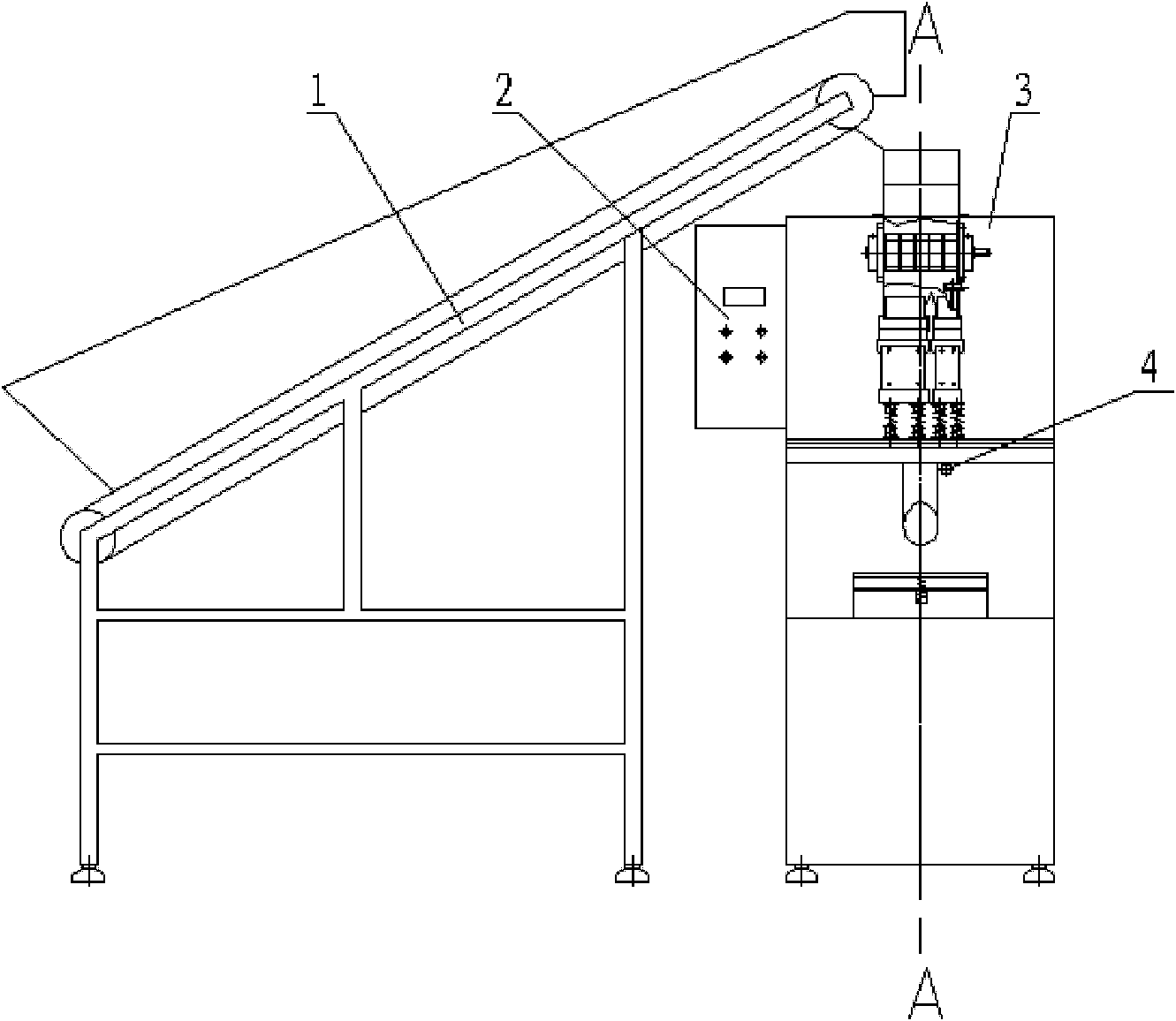

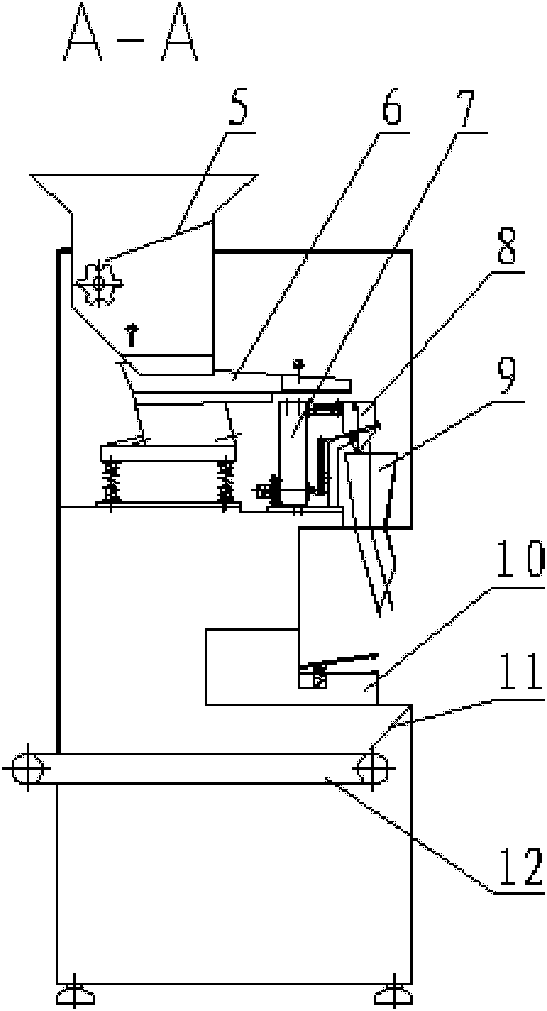

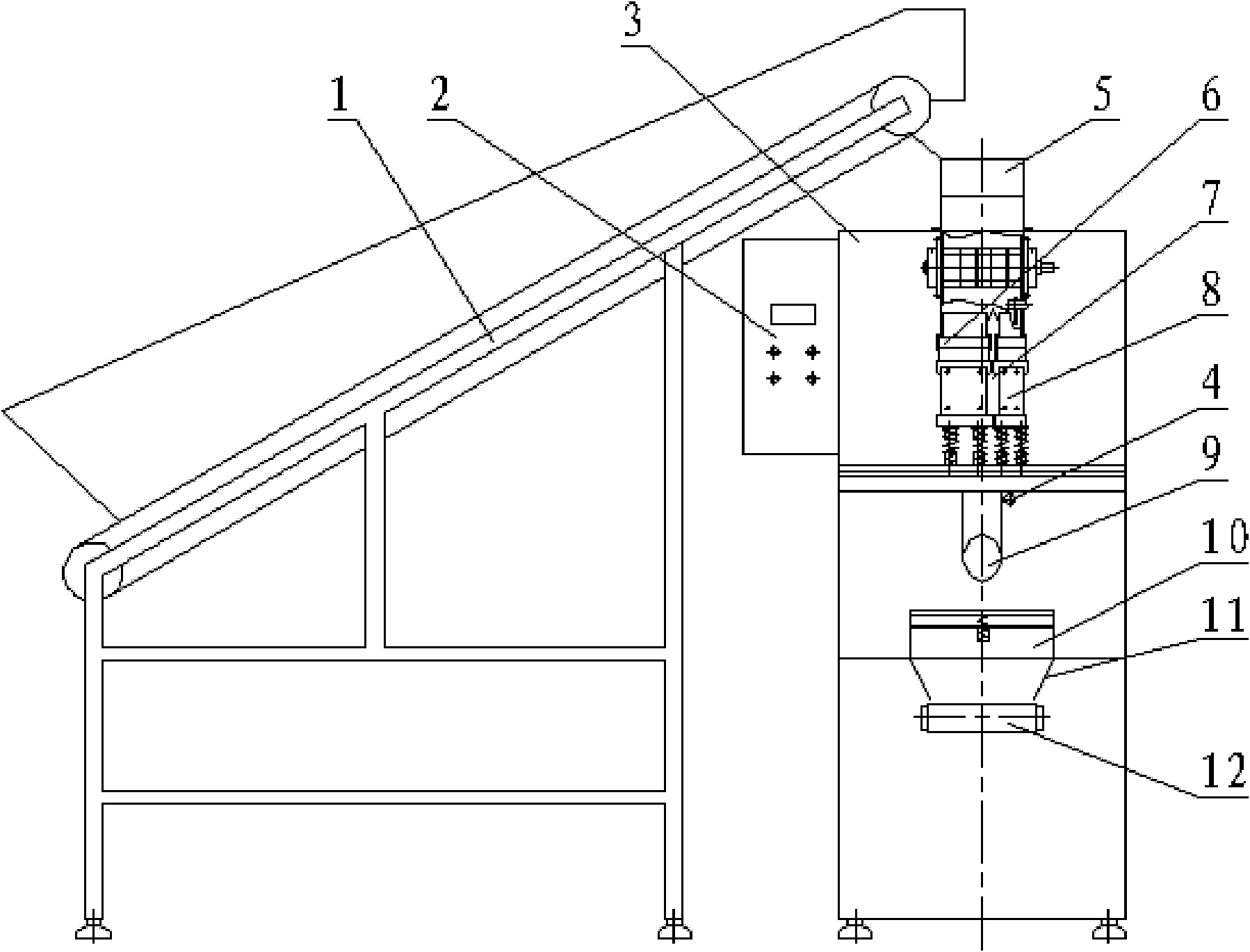

[0010] Referring to accompanying drawings 1 and 2: (1) The storage and conveying system 1 is composed of a slope conveyor with a transverse partition and side baffles to form a storage tank; (2) The top hopper system 5 is equipped with upper and lower material levels Sensors, double twisters and material layer thickness sensors; (3) When the top hopper is installed, there is a certain gap between the left, right and rear sides of the top hopper and the large and small vibrating feeders; (4) The vibrating feeding system 6 adopts large and small vibration The feeders start work at the same time, the large vibrating feeder quickly feeds the material until it is close to the set value and stops, and the small vibrating feeder continues to accurately feed the material to the set value before stopping; (5) The door opening device 7 adopts a frame (6) The weighing bucket in the weighing device 8 adopts a cantilever installation, and the movable side is hinged on the fixed side; (7) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com