Automatic chopstick detachment machine

An automatic and driving mechanism technology, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems that combined chopsticks cannot be recycled again, difficult to disassemble, and high scrap rate, so as to achieve strong equipment reliability, high processing efficiency, The effect of low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

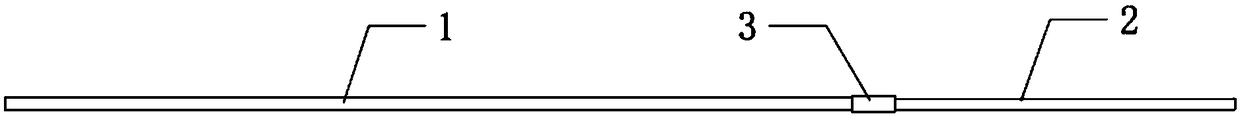

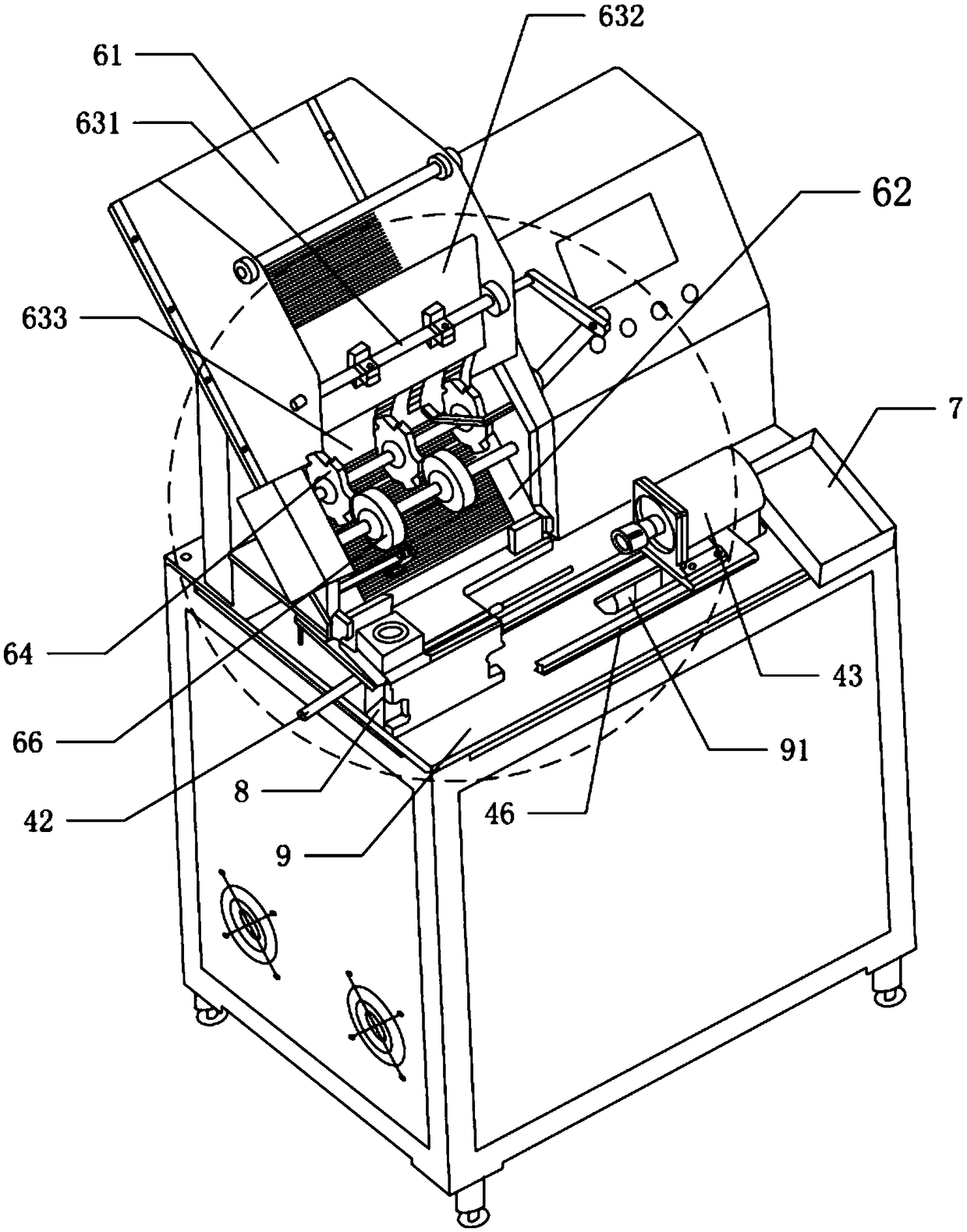

[0041] This embodiment provides an automatic chopsticks removal machine, comprising a feeding mechanism 6, a transfer mechanism 5 and a chopsticks removal assembly 4, the combined chopsticks are placed in the feeding mechanism 6, the feeding mechanism 6 is used to provide combined chopsticks, and the transfer mechanism 5 is used Between the combined chopsticks discharged from the feeding mechanism 6 are transferred to the chopsticks removal assembly 4, the chopsticks removal assembly 4 is used to remove the bamboo part 2 from the combination chopsticks.

[0042] Specifically, such as figure 2 and image 3As shown, the chopsticks removing assembly 4 includes a first driving mechanism 41, a chopsticks pushing device 42, a chopsticks holding mechanism 44 and a chopsticks removing motor 43, and the chopsticks holding mechanism 44 is used to fix the bamboo part 2 of the combined chopsticks. The chopsticks removal motor 43 is a hollow shaft motor, the chopsticks locking mechanism ...

Embodiment 2

[0044] This embodiment provides an automatic chopsticks removal machine, comprising a feeding mechanism 6, a transfer mechanism 5 and a chopsticks removal assembly 4, the combined chopsticks are placed in the feeding mechanism 6, the feeding mechanism 6 is used to provide combined chopsticks, and the transfer mechanism 5 is used Between the combined chopsticks discharged from the feeding mechanism 6 are transferred to the chopsticks removal assembly 4, the chopsticks removal assembly 4 is used to remove the bamboo part 2 from the combination chopsticks.

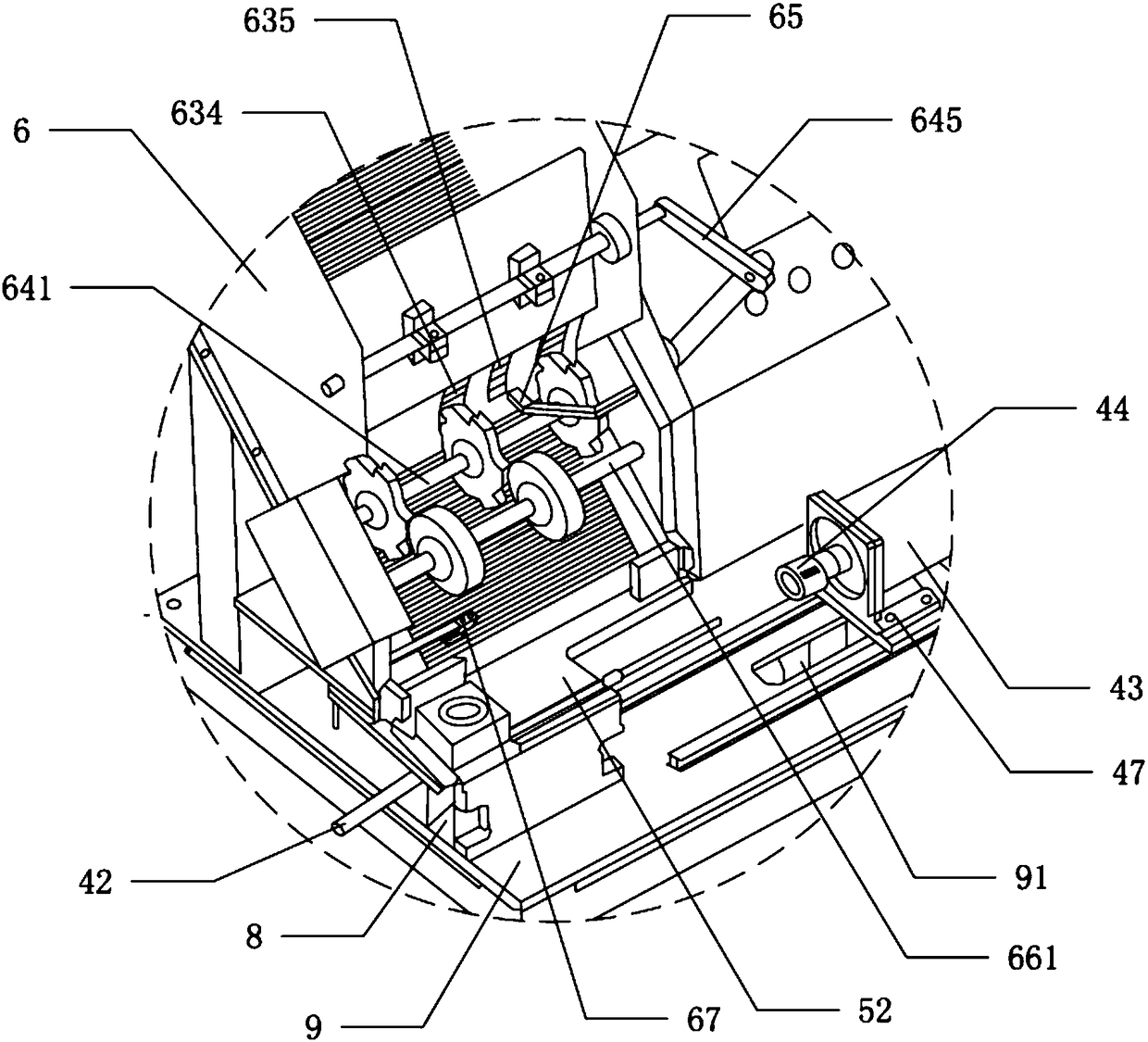

[0045] Specifically, such as Figure 4 and Figure 5 As shown, the chopsticks removing assembly 4 includes a first driving mechanism 41, a chopsticks pushing device 42, a chopsticks holding mechanism 44 and a chopsticks removing motor 43. The motor 43 is fixedly connected with the mount 49, the rotating shaft of the chopsticks motor 43 passes through the mount 49, the shell of the chopsticks motor 43 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com