Bottle cap for storing raw material

A technology of raw materials and bottle caps, applied in the field of bottle caps, can solve problems such as insufficient sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

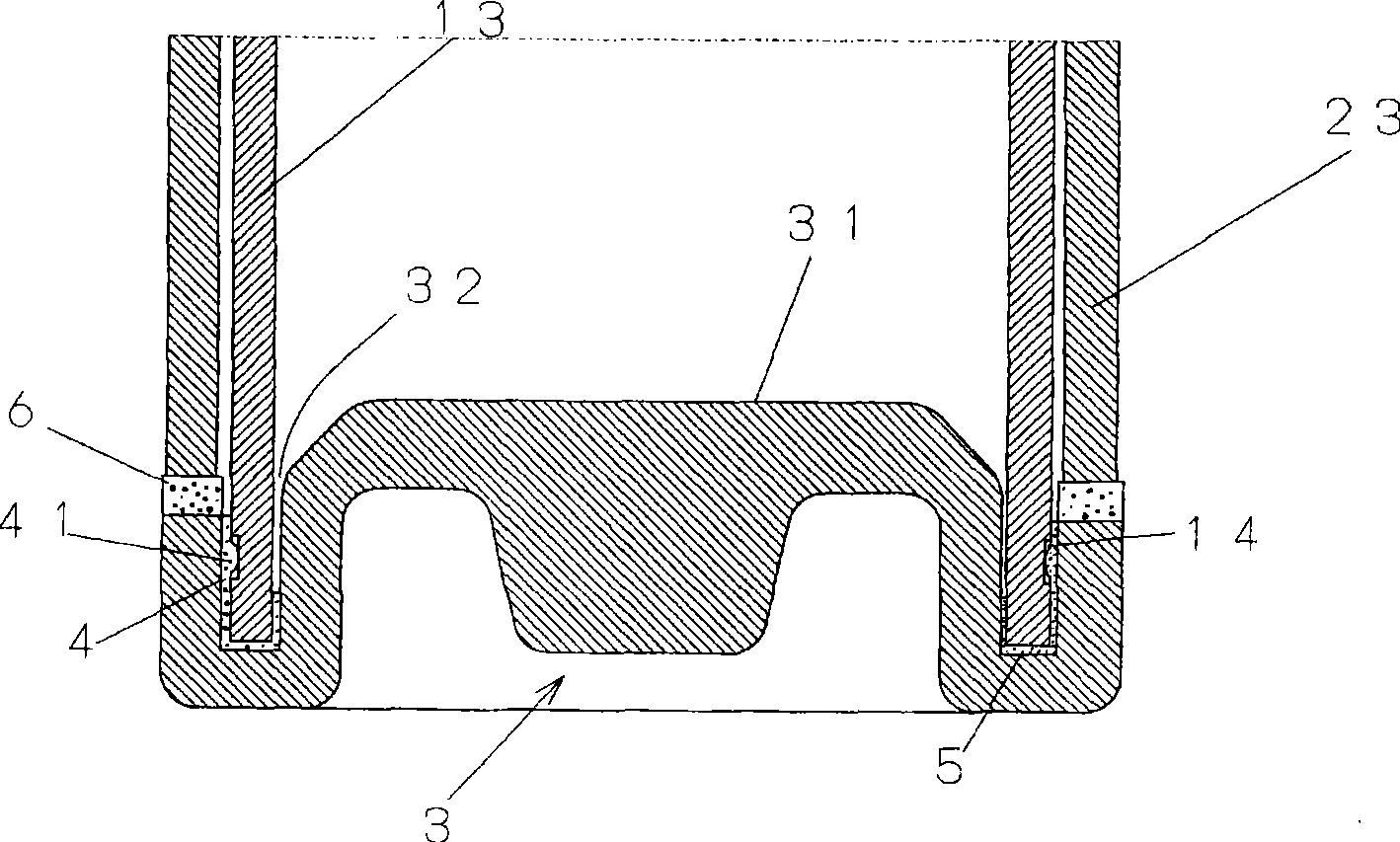

[0054] The implementation of the invention will be explained according to the diagram below

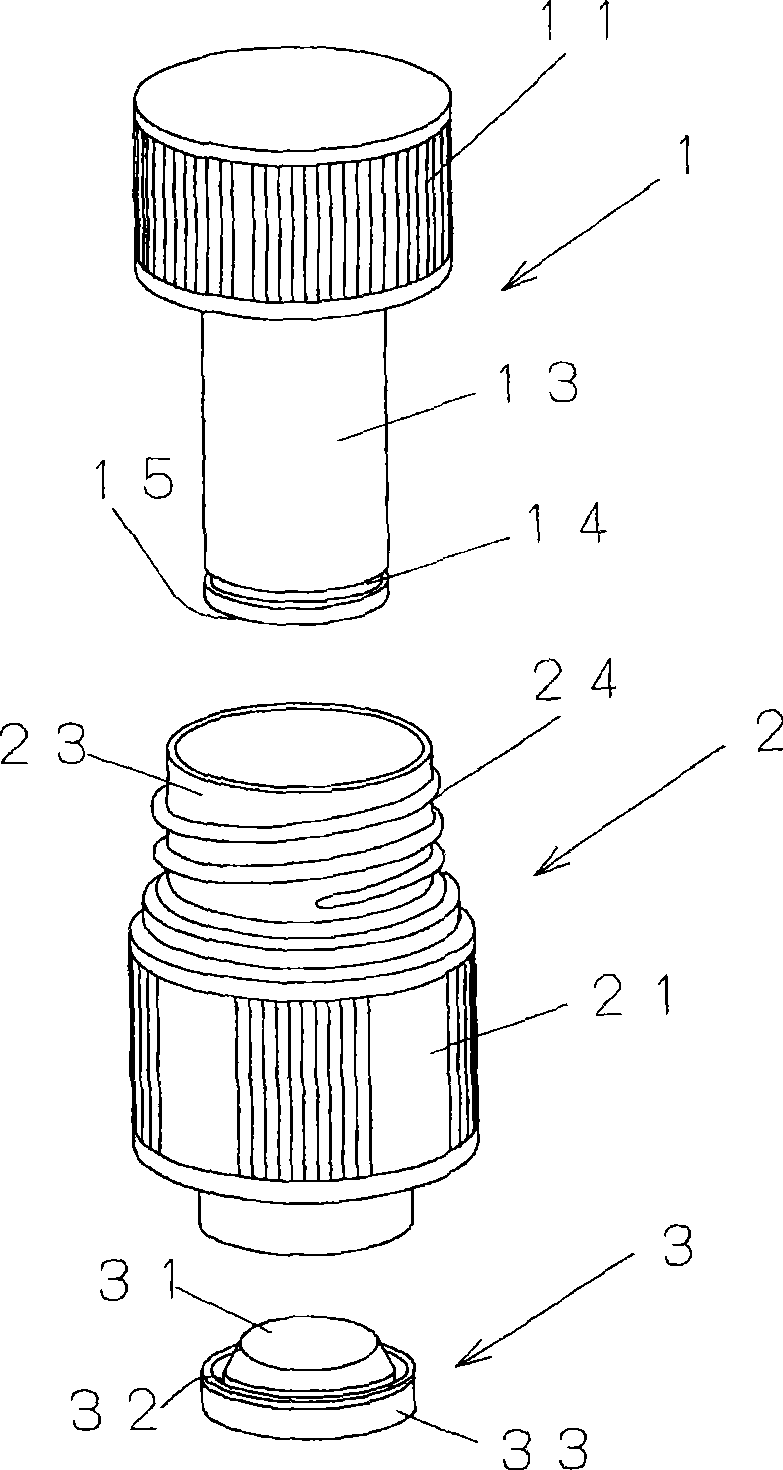

[0055] figure 1 It is an exploded perspective view of the raw material storage type bottle cap of the present invention.

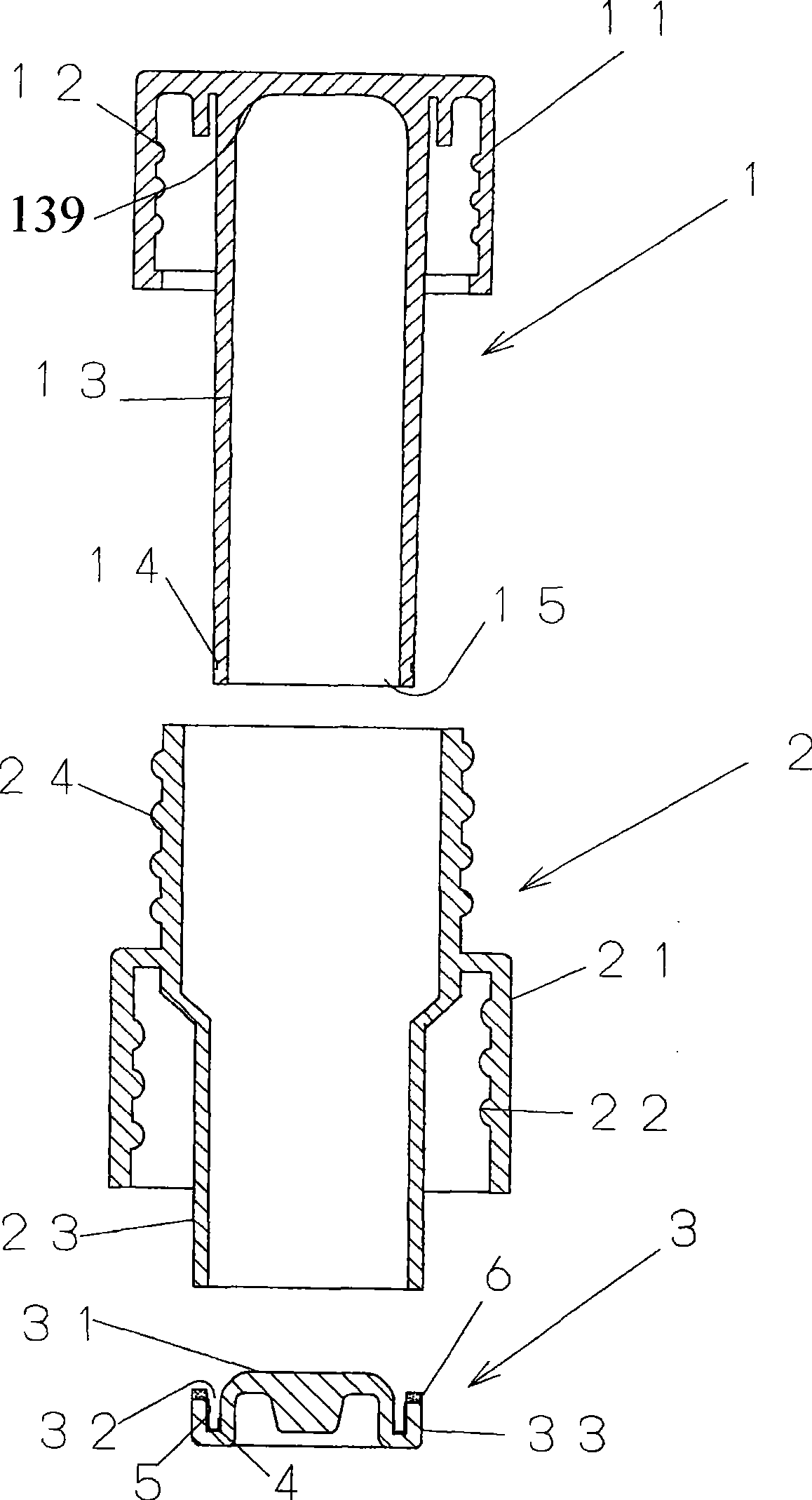

[0056] figure 2 It is an exploded longitudinal sectional view of the raw material storage type bottle cap of the present invention.

[0057] The bottle cap is composed of an upper cap 1 and a lower cap 2 . The bottle cap accommodates the raw materials, and when the cap is opened, it falls into the bottle, which is basically consistent with the various disclosed technologies involved.

[0058] The lower cap 2 is composed of a lower cap body 21 and a guide tube 23, wherein the inner peripheral surface of the lower cap body 21 is formed with an internal thread 22 that is rotatably engaged with the bottle mouth, and an integrally formed guide tube 23 protrudes up and down at its center. The outer wall of the upper cylinder portion of the guide cylinder 23 opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com