Solar cell silicon chip detecting system

A technology of solar cells and detection systems, applied in the field of detection systems, can solve the problems of increased probability, detection time, cost, undetectable, sorting, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

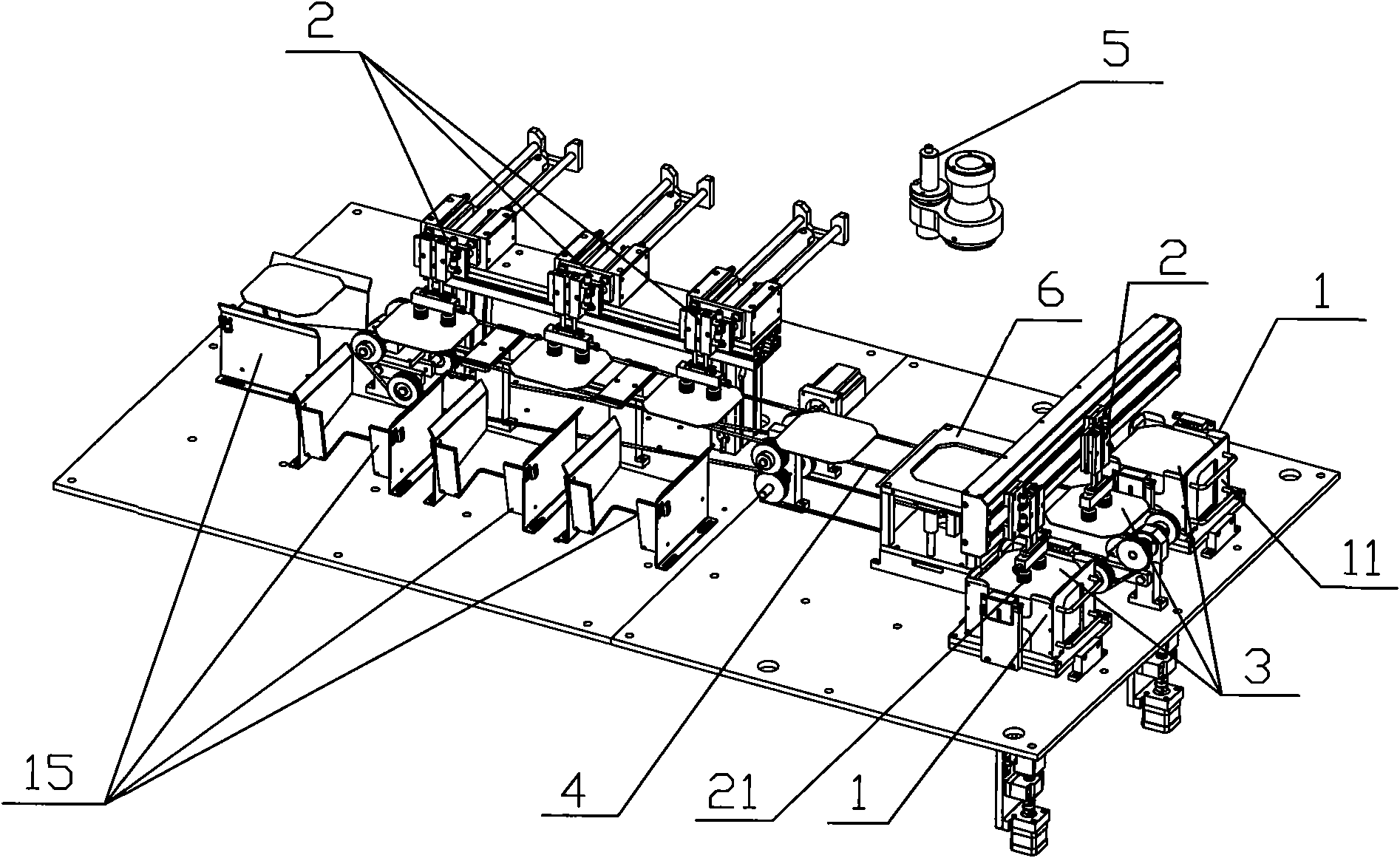

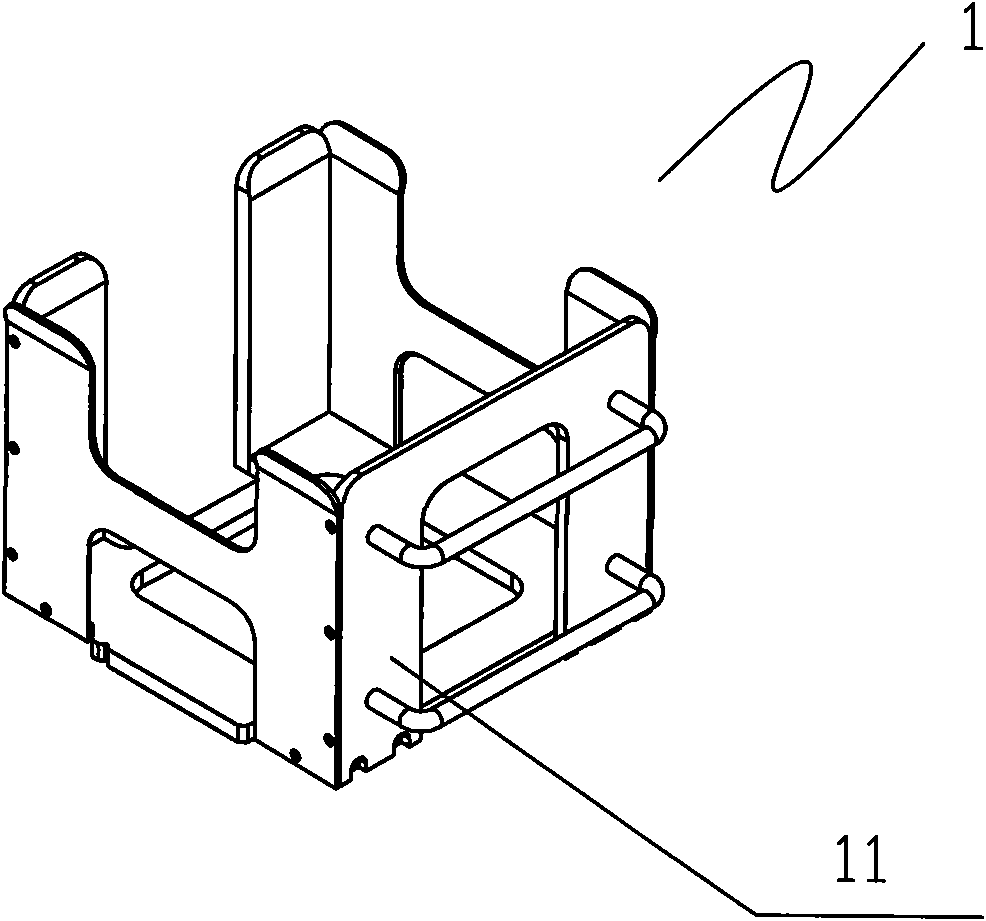

[0043] figure 1 It is a schematic diagram of a silicon wafer detection system for solar cells using the principle of photoluminescence according to the present invention. From right to left in the figure, along the silicon wafer conveyor belt, there are feeding area, exposure area, inspection waiting area, and sorting area. The area includes a loading box 1 and a manipulator 2. The front panels 11 of the two loading boxes 1 can be opened around the shaft at the bottom of the loading box 1, and the silicon wafer 3 can be placed in the loading box 1 by hand (such as figure 2 ), the manipulator 2 extracts the silicon wafer 3 through the suction cup 21 and puts it on the conveyor belt 4. After the silicon wafer 3 is placed on the conveyor belt 4, it is known to the electric control and UI, and the silicon wafer 3 is transported to the exposure area through the conveyor belt 4.

[0044] The exposure area is provided with an illumination system, an imaging system 5 and a photofluor...

Embodiment 2

[0052] The difference between embodiment 2 and embodiment 1 is that electroluminescence is used to expose and image the silicon wafer, and an electroluminescence limit mechanism is designed according to the principle of electrofluorescence. The imaging system no longer needs an illumination system. 1 is basically the same.

[0053] The principle of embodiment 2 is to cause the silicon wafer to emit light by applying current to the silicon wafer of the solar cell, and the quality of the silicon wafer can be judged according to the luminous intensity. The photoluminescent detection method can be used for all process detection after the PN junction is formed, while the electroluminescent detection method can only be used after screen printing.

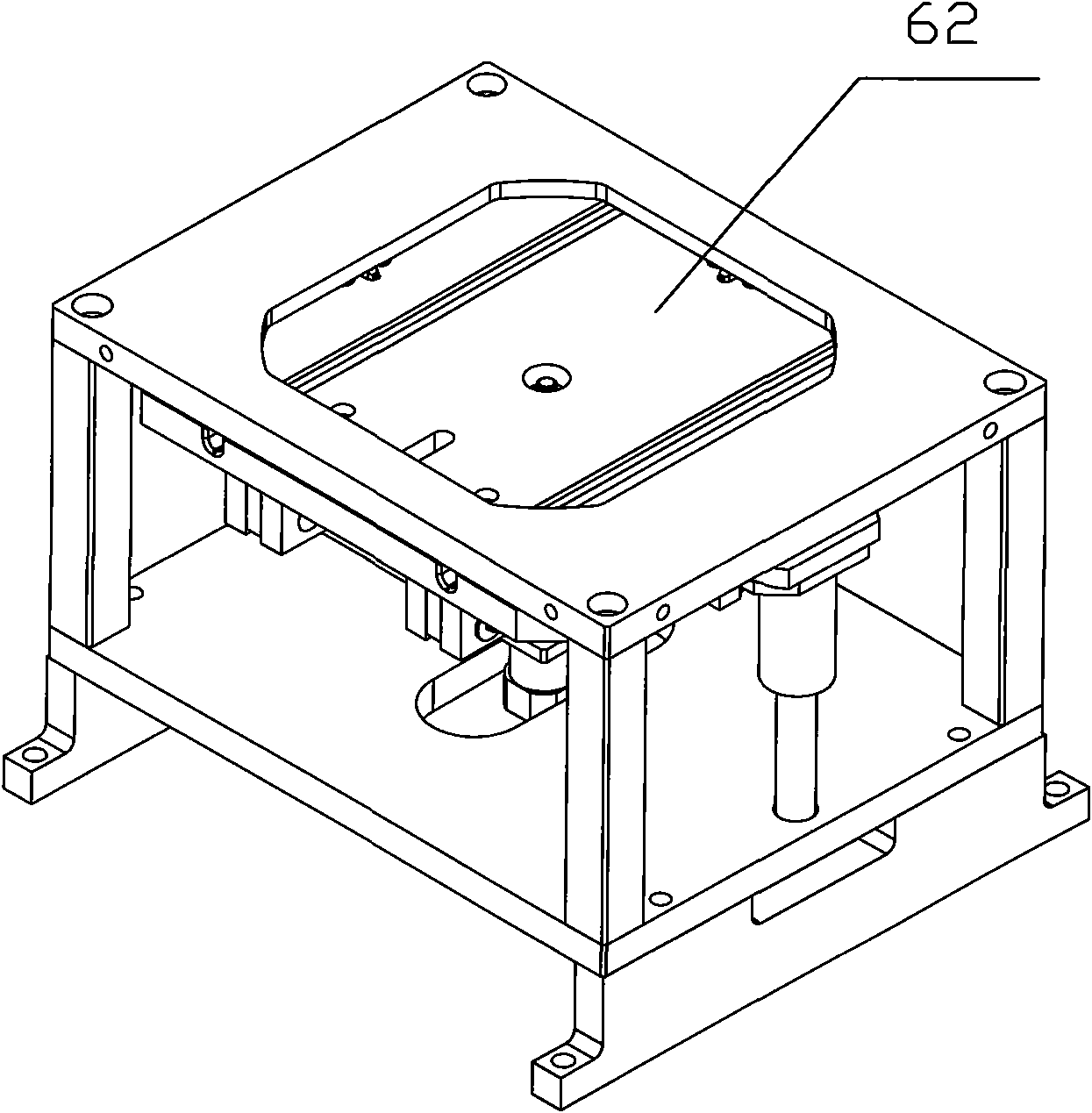

[0054] Figure 12 It is a schematic diagram of the electroluminescence solar cell silicon wafer detection system of embodiment 2, and the photoluminescent limiting mechanism 6 is different in that the electroluminescent limiting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com