Cooling device

A technology of cooling device and cooling chamber, which is applied in the direction of packaging, etc., can solve the problems of normal transportation of materials that affect normal operation, incomplete blanking, etc., and achieve the effects of reasonable cooling and transportation, saving time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

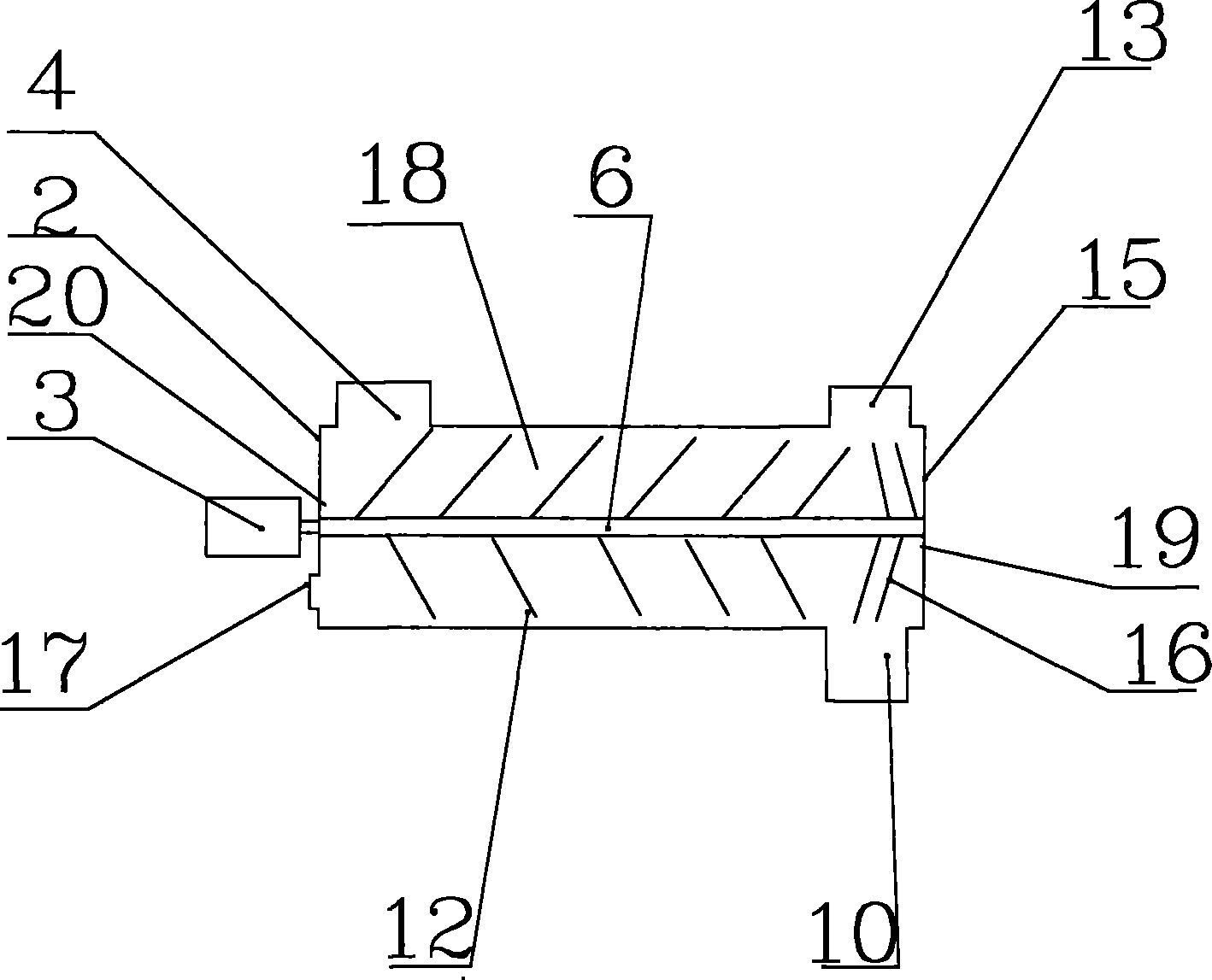

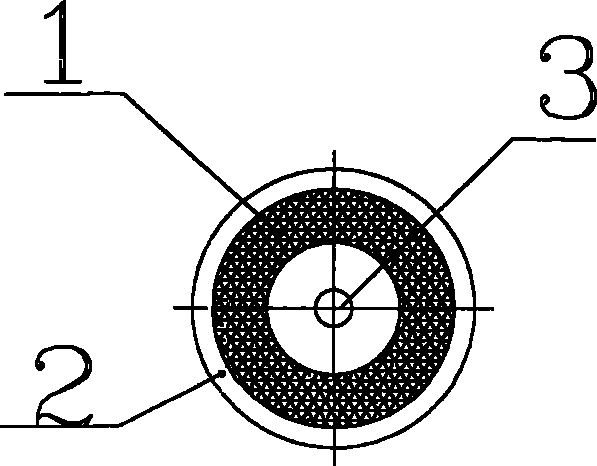

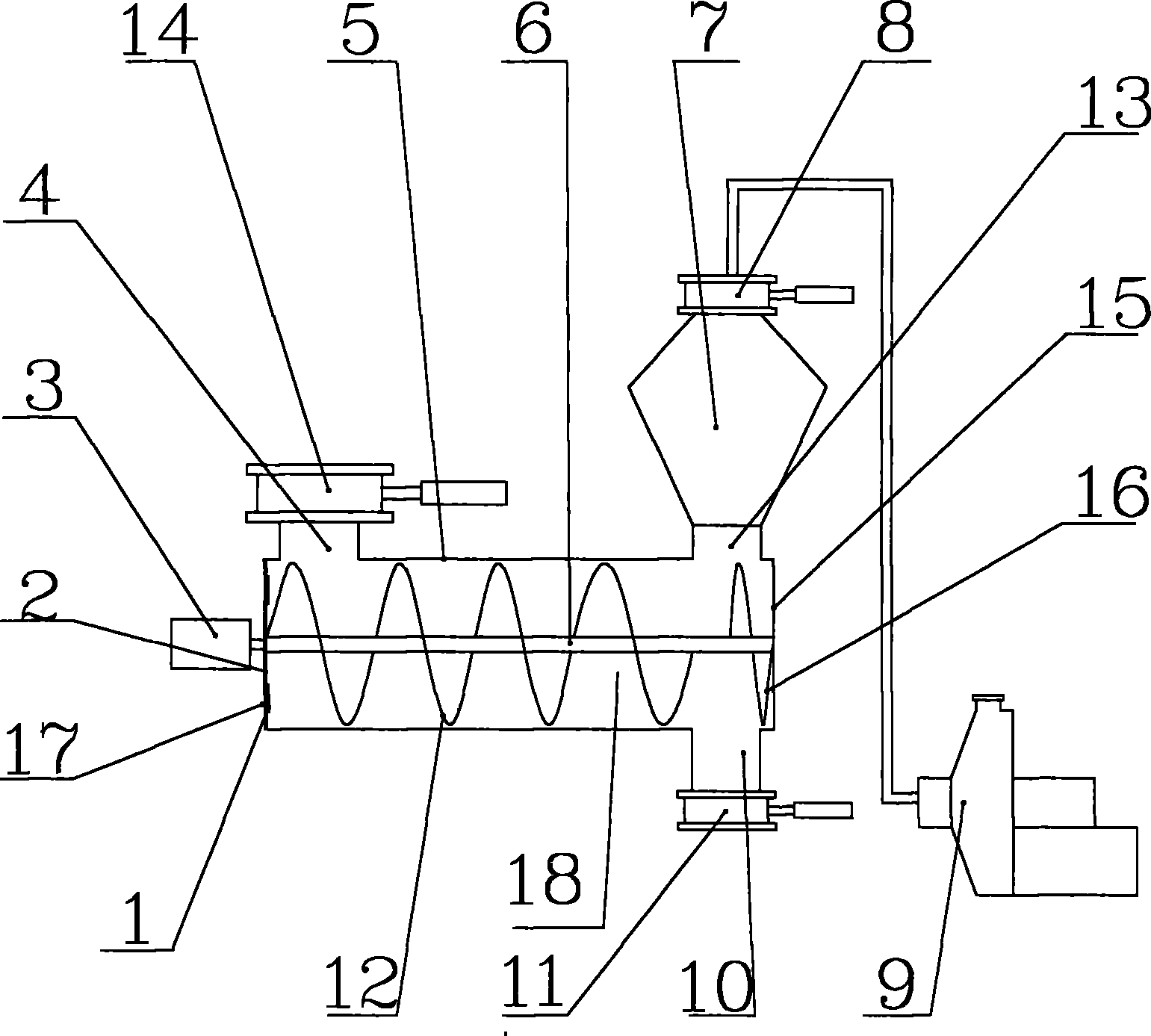

[0034] Cooling device of the present invention such as figure 1 As shown, it can be seen from this figure that it includes a cylindrical cooling bin 5, and the cooling bin 5 is laterally provided with a front end cover 2 and a rear end cover 15; The front end cover 2 is provided with a cooling bin material inlet 4, and a cooling bin material outlet 10 is provided at the bottom of the cooling bin 5 and near the rear end cover 15; in addition, on the front end cover 2 of the cooling bin 5 A cooling air inlet 17 is provided, and a cooling air outlet 13 is arranged on the top of the cooling chamber 5 and near the rear end cover 15, so that the cooling air enters the cooling chamber 5 through the cooling air inlet 17 and passes through After circulating, it is discharged from the cooling air outlet 17. In order to realize the conveying of the material while cooling the material, the cooling device of the present invention is also provided with a screw agitating conveyor 18 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com