Energy-gathered charging structure for assisting in sampling of foreign planet minerals

A technology for shaped charge and minerals, applied in sampling devices, weapon accessories, blasting tubes, etc., can solve problems such as unfavorable collection and sampling work, scattering of mineral fragments, etc., and achieve the effects of small incidental damage, good safety, and small load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0031] This embodiment provides a shaped charge structure for assisting in the sampling of extraterrestrial minerals, which can be driven by less explosive explosions in a low-gravity, vacuum-free and oxygen-free environment to form an annular jet to penetrate hard minerals, and at the same time, drive flyers Breaking up bulk minerals facilitates sampling.

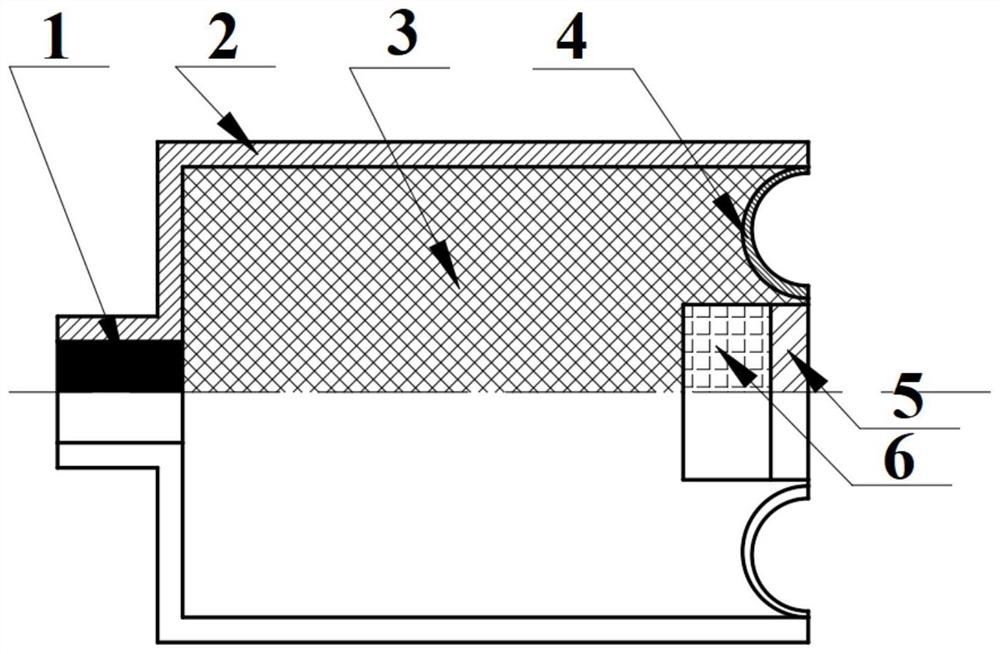

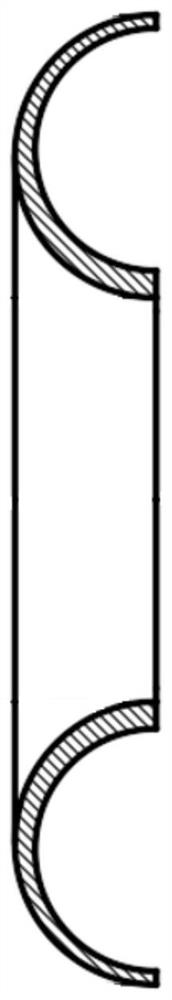

[0032] Such as figure 1 As shown, the shaped charge structure includes: an initiation mechanism 1 , a casing 2 , an explosive column 3 , an annular charge cover 4 , flyers 5 and a buffer body 6 .

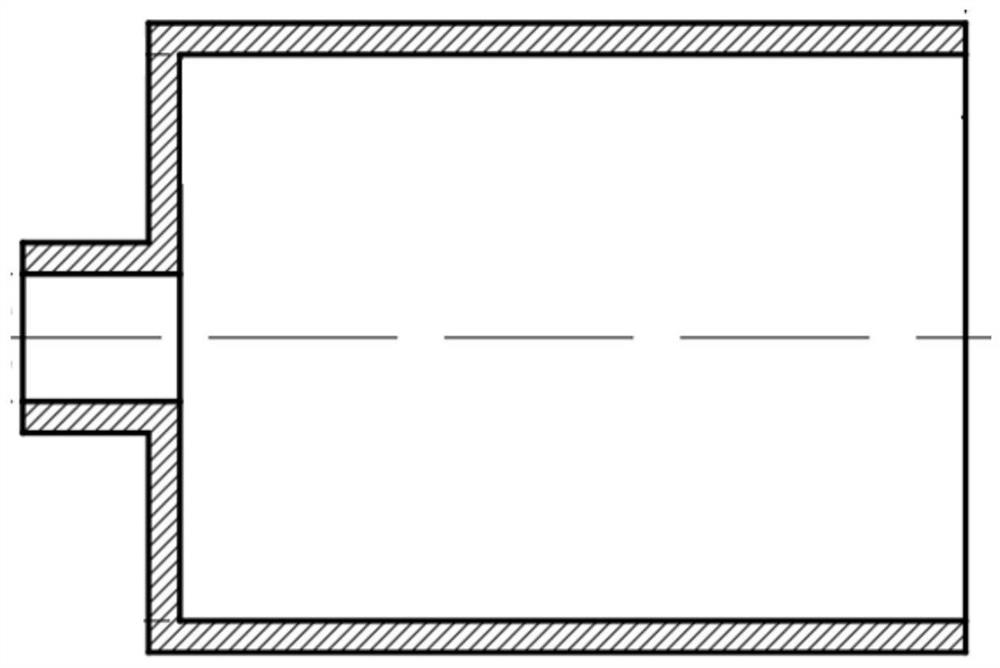

[0033] The connection relationship of the shaped charge structure is as follows: figure 2 As shown, the casing 2 is a stepped shaft-shaped circular tube with openings at both ends, and the explosive column 3 is coaxially filled in the inner cavity of the large end of the casing 2, so that one end of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com