Method and device for shaping foodstuffs and the like, and shaped product

A technology for shaping devices and ingredients, applied in special positions of vehicles, transportation and packaging, metal processing, etc., can solve problems such as troublesome input and removal operations, inability to achieve processing, and increase overall operating time, and achieve excellent and smooth work efficiency. draining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

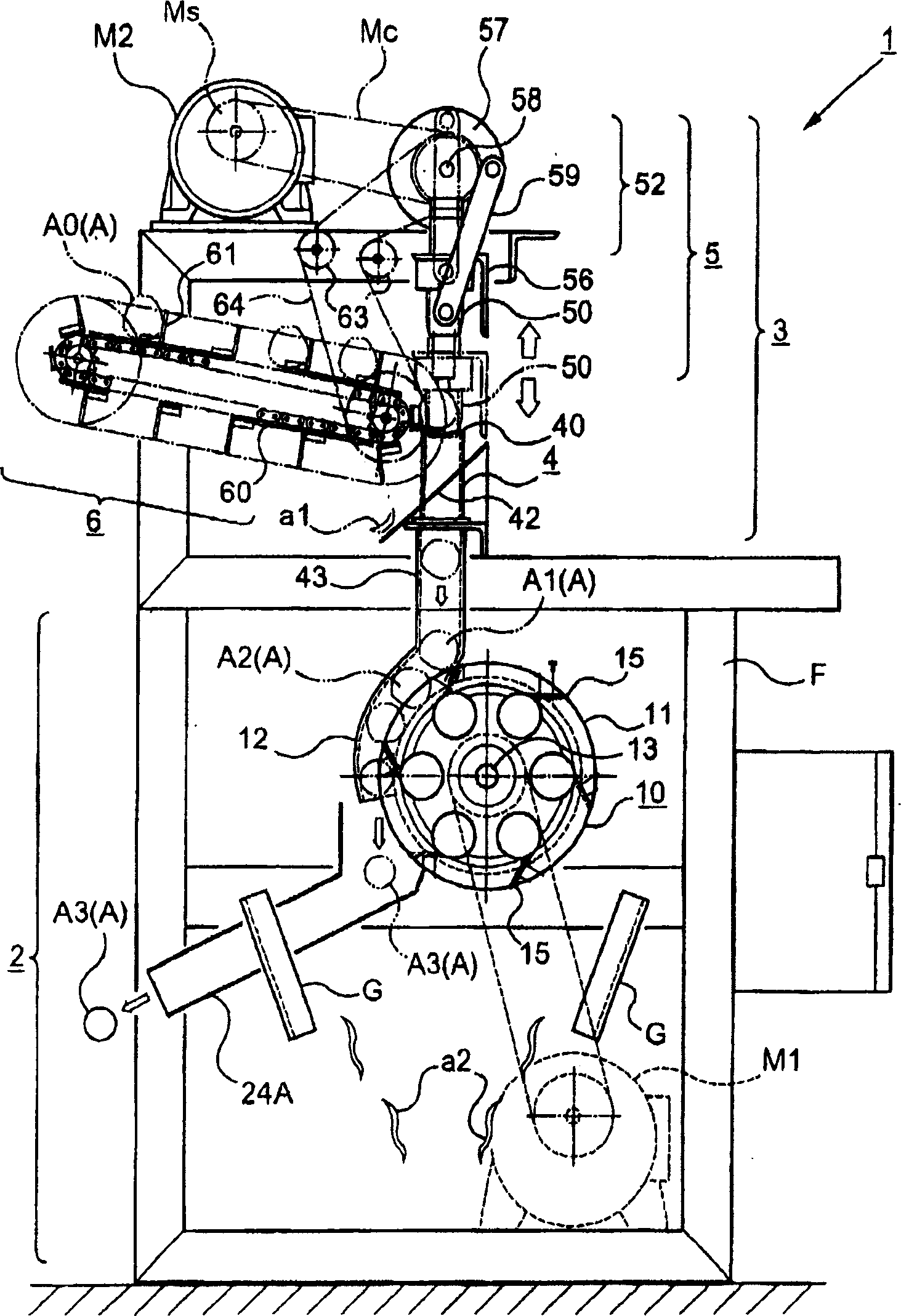

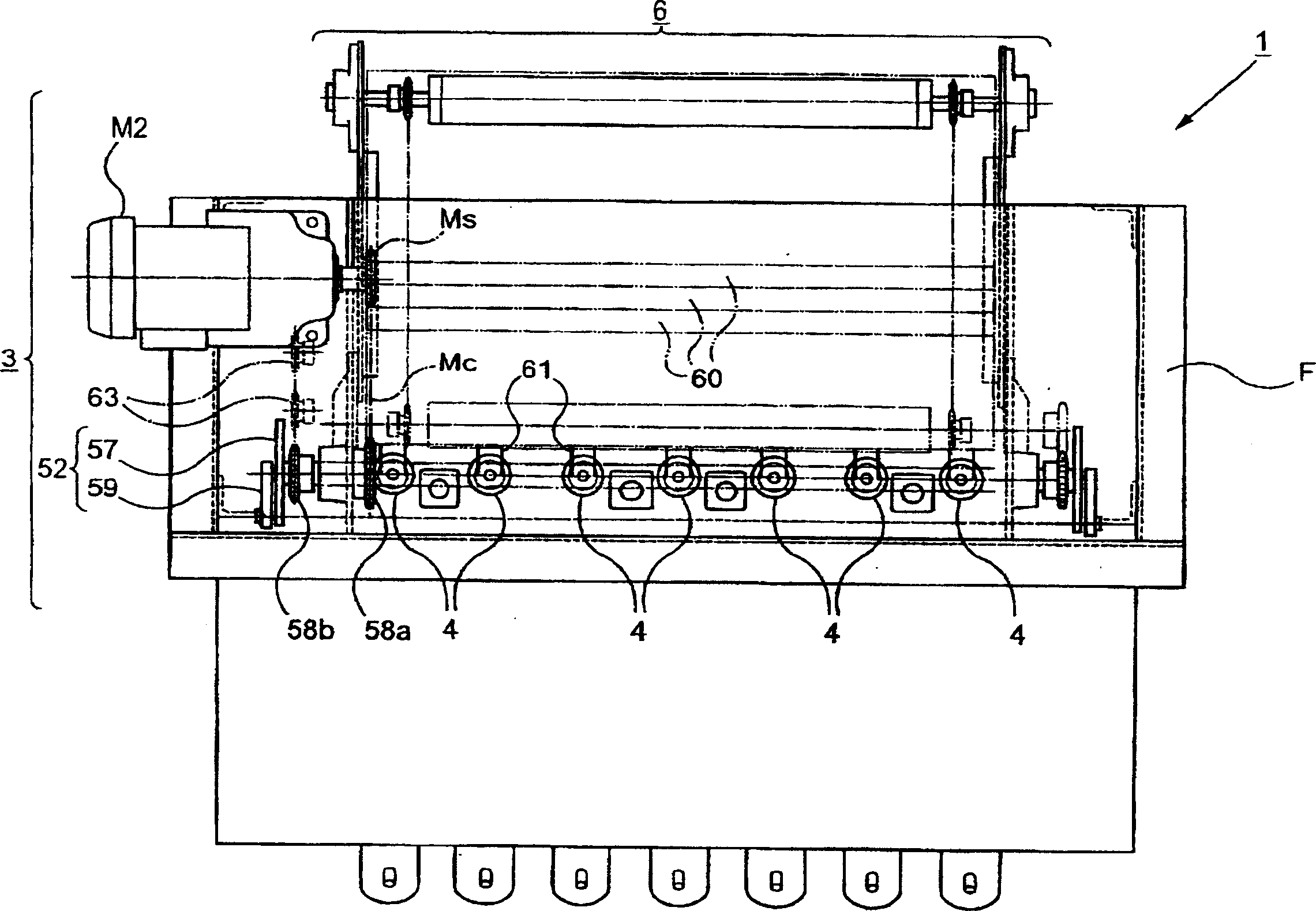

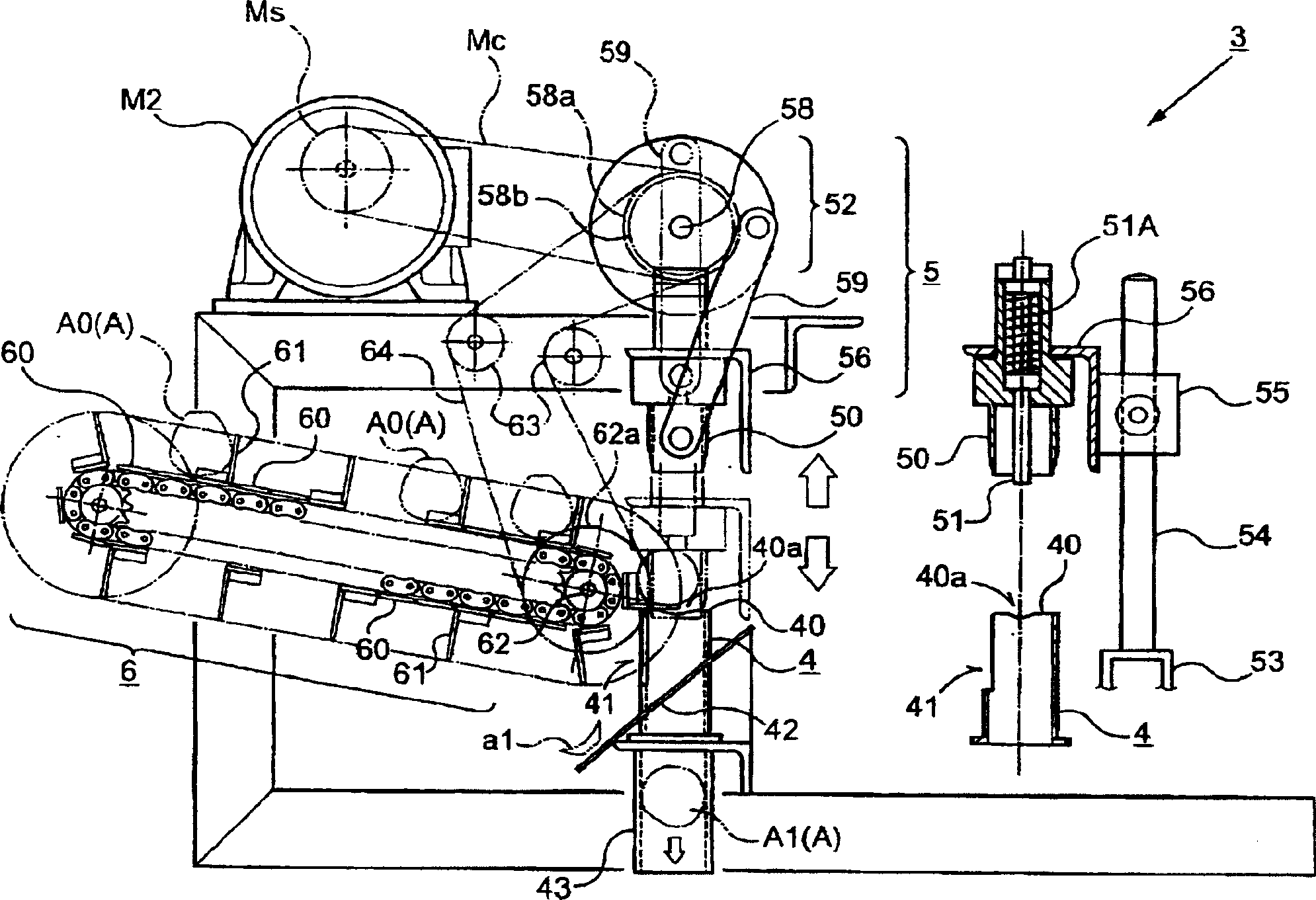

Examples

Embodiment approach

[0094] The above is the basic embodiment of the present invention, and other various changes can be made.

[0095] (6) Changes in the pre-processing device

[0096] As the pre-processing device 6, a slat conveyor is adopted in the implementation and the support rod 61 is substantially vertically arranged on the conveying surface, and it can also be used as Figure 8 As shown, the workpiece A0 is grasped by the robot arm 65 and placed on the receiving cylinder 4 by the robot arm 65 .

[0097] another example Figure 9 As shown, the receiving cylinder 4 can also be made into a structure that can move up and down at the center of the bowl-shaped recess 44. When receiving the workpiece, as shown in FIG. Figure 9 As shown in (a), the receiving cylinder 4 descends below the concave portion 44 to receive the workpiece. After receiving, as shown in Figure 9 As shown in (b), the receiving cylinder 4 rises. Incidentally, the relay tank 43 is a flexible corrugated tube.

[0098] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com