Aluminum oxide ball production line

An alumina ball and production line technology, which is applied in the extrusion and granulation of raw materials, chemical instruments and methods, chemical/physical processes, etc. The effect of high production efficiency, reducing labor intensity and improving granulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

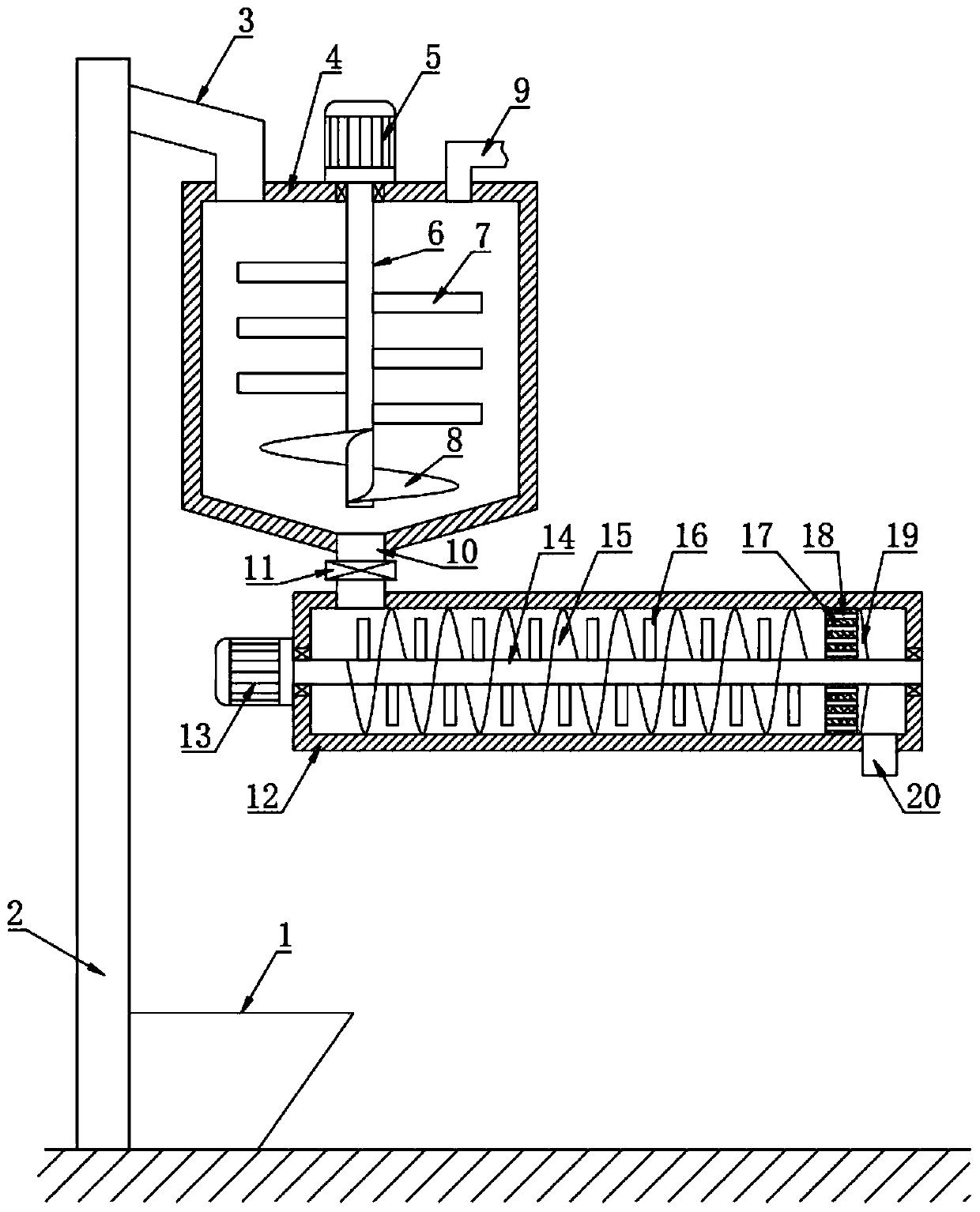

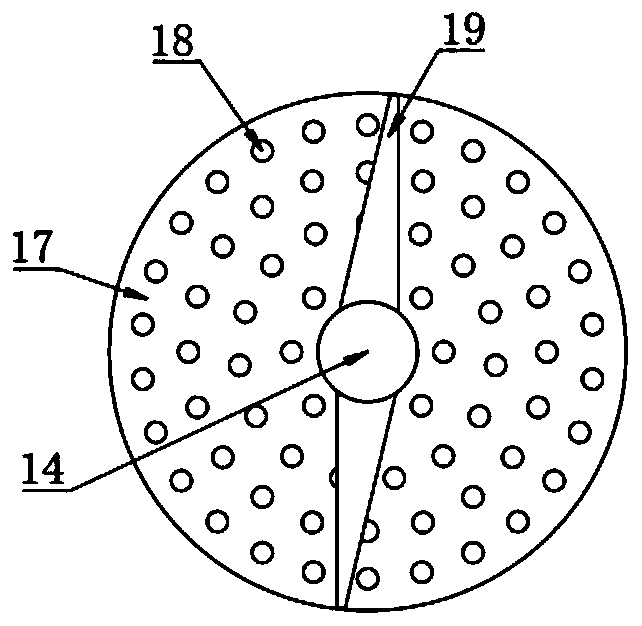

[0028] see Figure 1~2 , in the embodiment of the present invention, an alumina ball production line includes a mixing box 4 and a granulation barrel 12, the mixing box 4 and the granulation barrel 12 are fixed above the ground by brackets, how to fix it is not required, the mixing box 4. The bottom is funnel-shaped and the outlet at the bottom is connected to the feed port on the left side of the granulation barrel 12 through the feeding pipe 10. The feeding pipe 10 is provided with a solenoid valve 11, and the raw materials are mixed through the mixing box 4. After mixing The raw material enters the granulation barrel 12 through the feeding pipe 10 for granulation; the axis position of the mixing box 4 is provided with a first rotating shaft 6, and the top of the first rotating shaft 6 is rotatably connected with the top wall of the mixing box 4; the first rotating shaft 6 is fixedly connected with a number of first stirring blades 7, the first stirring blades 7 are staggere...

Embodiment 2

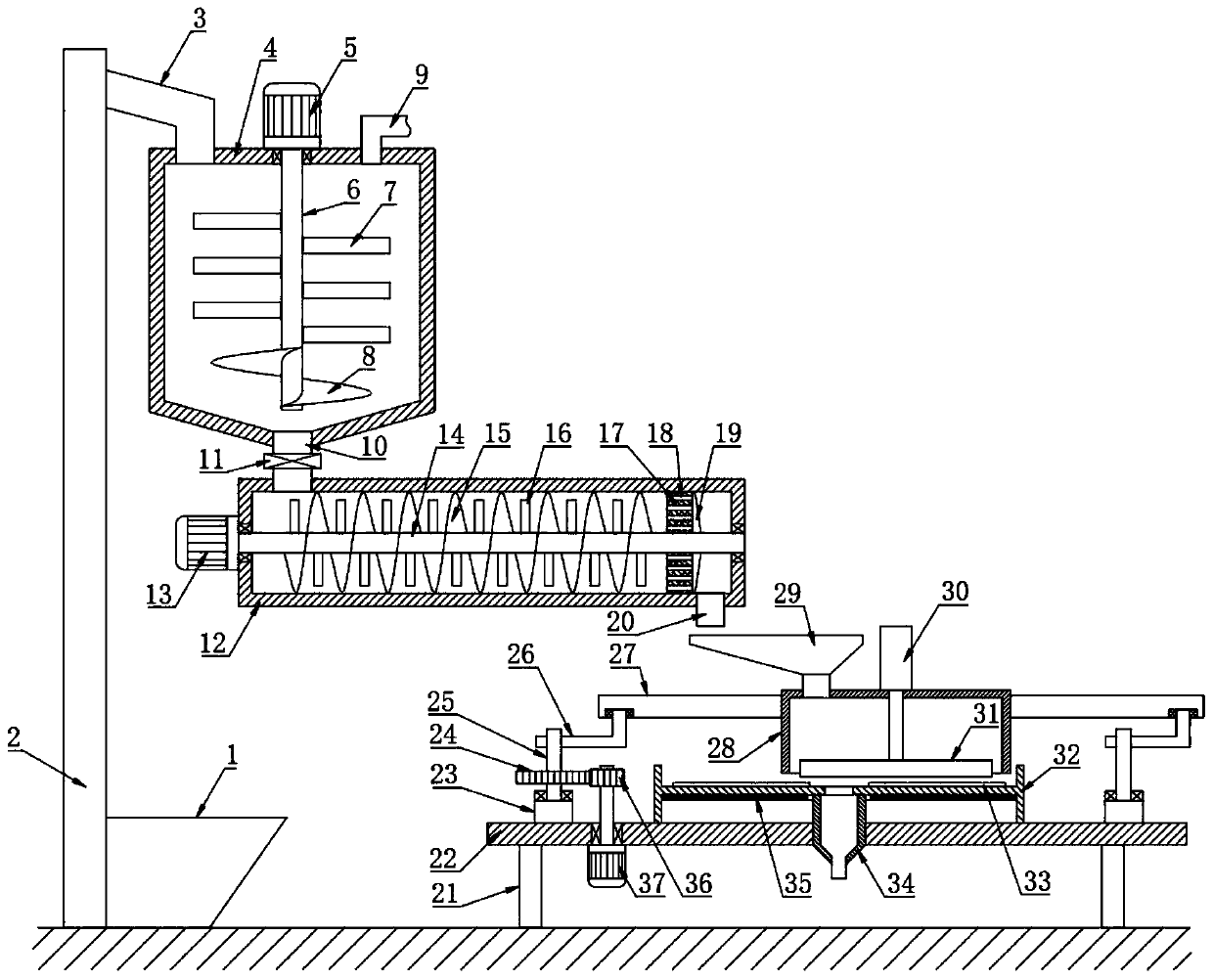

[0032] see Figure 3-4 , on the basis of Embodiment 1, it also includes a support plate 22 and a storage tank 28, the support plate 22 is arranged on the ground through the legs 21, and a rubbing disc 32 is fixedly arranged on the top of the support plate 22, and the storage tank 28 is located above the rubbing plate 32; the top of the storage tank 28 is also provided with a receiving hopper 29, and the receiving hopper 29 is located below the discharge pipe 20; the alumina particles obtained by granulation fall into the storage tank 28; The outer surface of the bucket 28 is fixedly connected with several support arms 27, the bottom of the support arm 27 is connected with the crank 26 through the bearing, and the top of the support plate 22 is connected with several third rotating shafts 25 which cooperate with the crank 26 through the bearing 23 with seat. The top of the third rotating shaft 25 is fixedly connected with the corresponding crank 26 respectively; the center of t...

Embodiment 3

[0036] see Figure 5 , on the basis of embodiment 1 or 2, the material storage box 38 is also fixedly connected with the described feeding pipe 10, the material storage box 38 is located below the solenoid valve 11; the mixing box 4 discharges into the material storage box 38, closes Solenoid valve 11 can carry out new mixing, and the raw materials in the storage box 38 start to granulate. Due to the continuity of granulation and discharge, the rubbing of alumina balls starts at the same time when granulation is in progress; thus, mixing and granulation , Kneading can be carried out at the same time, which greatly improves the overall work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com