Automatic shoemaking production line for injection moulded shoes

A production line and injection-molded shoe technology, applied to shoemaking machinery, shoe lasts, footwear, etc., can solve the problems of single product production, complicated operation, and heavy labor, and achieve high production efficiency, stability, and stable quality standards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below based on the drawings.

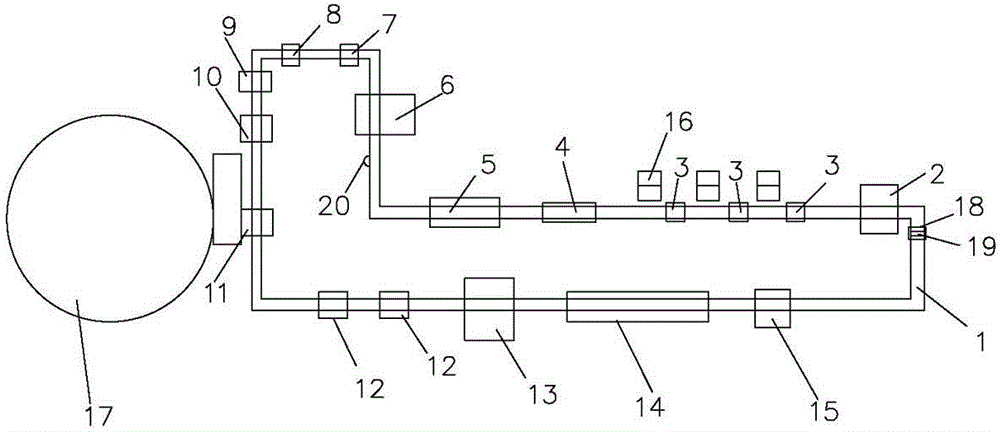

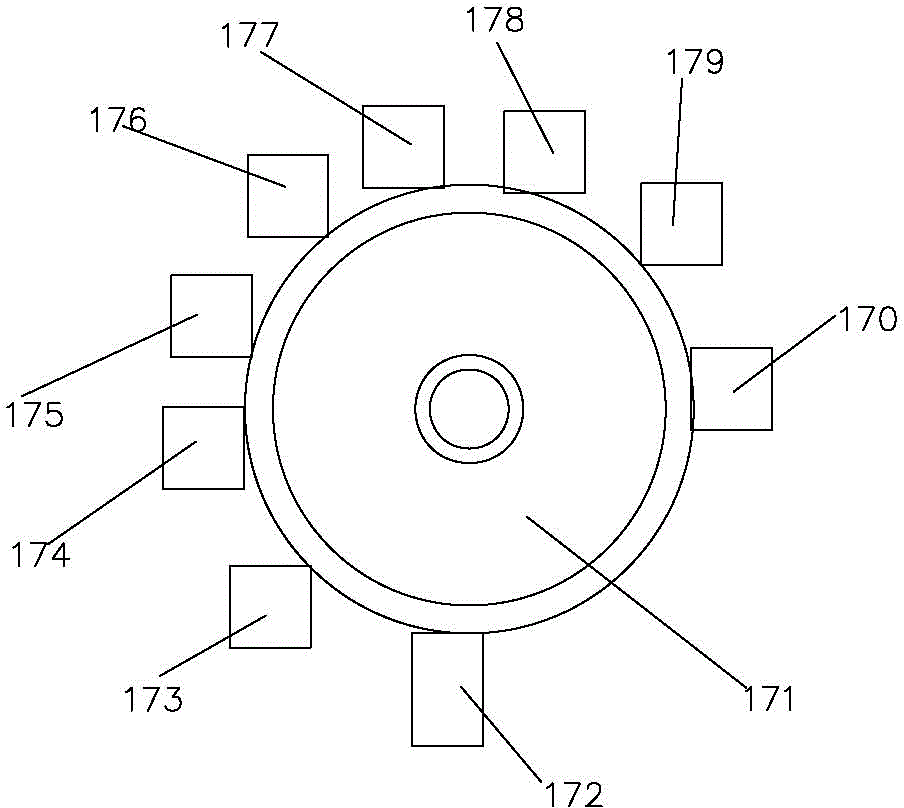

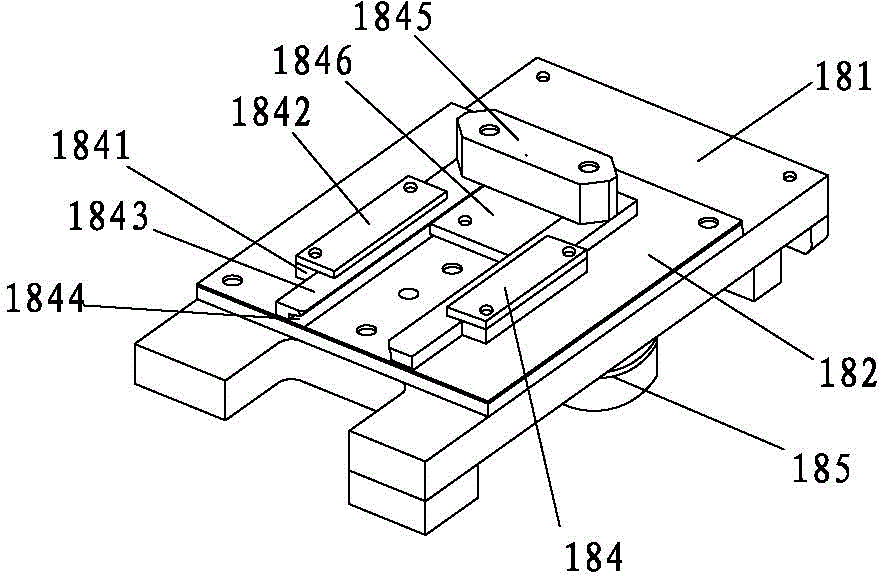

[0027] Such as figure 1 As shown, an automated shoe-making production line for injection-molded shoes includes a conveying line 1. At least one last tray 18 is provided on the conveying line 1, and a shoe last 19 is provided on the last tray 18. The conveying line 1 runs from the input end to The output end is provided with the first robot spraying lubricant workstation 2, multiple sets of last workstations 3, the steam heating box 4, the first oven 5, the second manipulator roughing station 6, the glue spraying station 7, the outsole plus Elastic part platform 8, compaction platform 9, singeing edge platform 10, third manipulator handling platform 11, multiple finished product flashing platform 12, fourth manipulator visual painting platform 13, freezing box 14, and cutting outsole processing platform 15, each One side of the last platform 3 is respectively provided with a shoe upper softening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com