Anisotropic high-strength wear-resisting repair material sample manufacturing mold

A high-strength, repairing material technology, applied in the preparation of test samples, manufacturing tools, ceramic molding machines, etc., can solve the problems of detection failure, broken, easy to fall off, etc., to achieve consistency, simple structure, easy disassembly and The effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

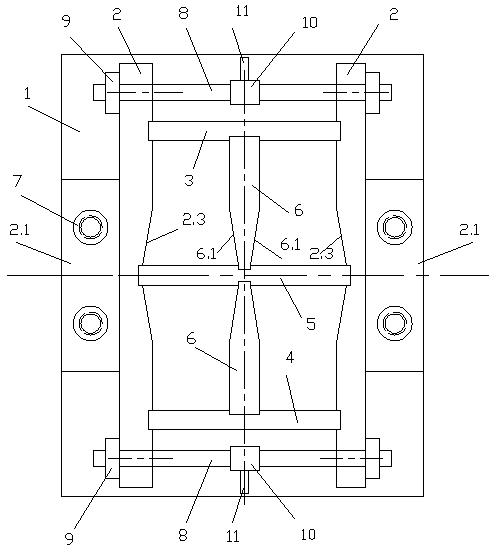

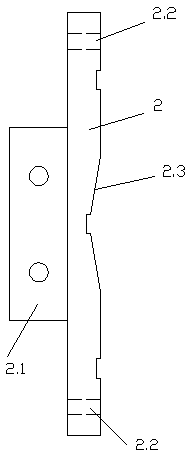

[0013] Example 1: A mold for making a sample of a heterosexual high-strength wear-resistant repair material, including a bottom plate 1, two symmetrical side plates 2 arranged on the bottom plate 1, and upper and lower horizontal plates arranged between the two side plates 2 ( 3, 4) and the horizontal partition 5 parallel to the upper and lower horizontal plates (3, 4) and located on the center line of the side plate 2, the center of the upper and lower horizontal plates (3, 4) and the horizontal partition 5 are provided with a vertical partition 6, the bottom plate 1. Side panels 2, upper and lower horizontal panels (3, 4), horizontal partitions 5 and vertical partitions 6 constitute four mold cavities, and the outer sides of the two side panels 2 are fixedly connected with connecting lugs 2.1. The sheet 2.1 is provided with connecting through holes, and the corresponding connecting through holes on the bottom plate 1 are provided with connecting holes, and the two are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com