Automatic lug brushing-cutting and frame-brushing machine for storage battery plate

An automatic brush and battery technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of powder loss and easy deformation of the electrode plate, and achieve the effects of reducing pollution, reducing production costs, improving production efficiency and finished product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

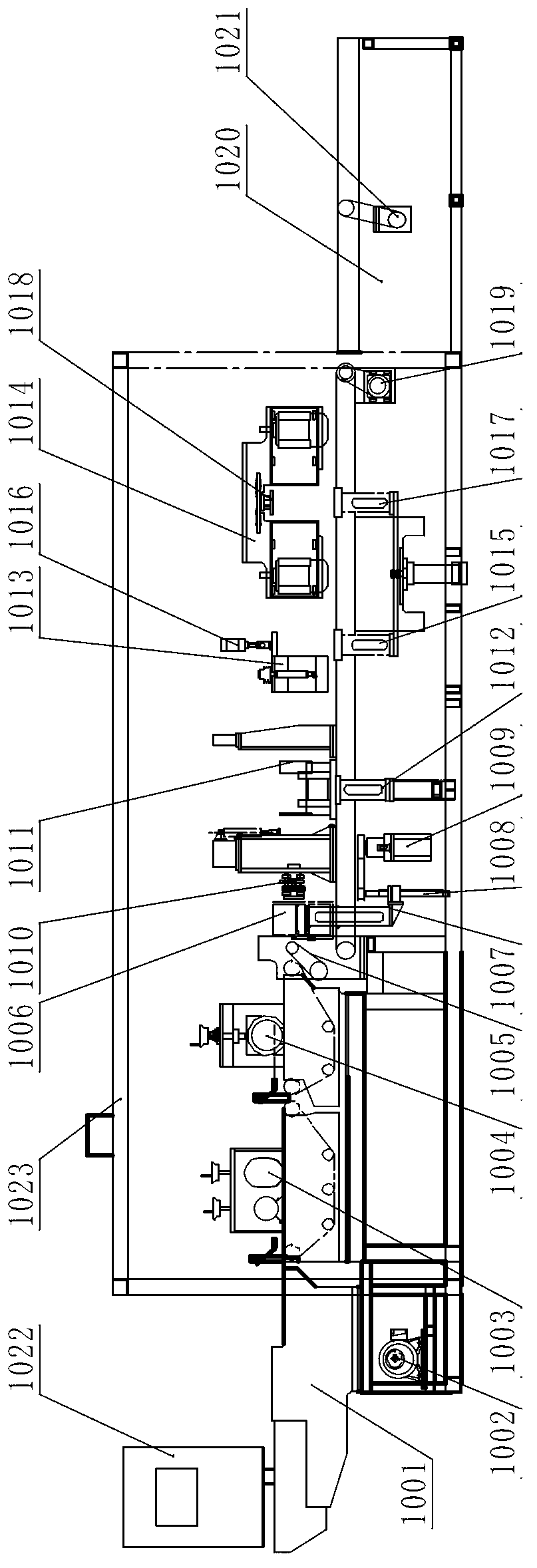

[0024] figure 1 It is the front view of the overall structure of the present invention, the frame 1023 is placed on the level ground, and the plate feeding device 1001, the pole plate conveying device, the transition device 1005 and the plate receiving device 1020 are installed in sequence at the head, middle and tail of the frame 1023. The two sides of the plate conveying device are equipped with brush ear device 1003, ear cutting device 1004, first edge brushing device 1013 and second edge brushing device 1014, stacking device 1006 vertically crossed with the plate conveying device, and finishing device 1011, wherein the ear brushing device 1003, the ear cutting device 1004, the first edge brushing device 1013, and the second edge brushing device 1014 are integrated on one piece of equipment, and the setting of the lamination device 1006 is the invention that overcomes the defects of the prior art key part of .

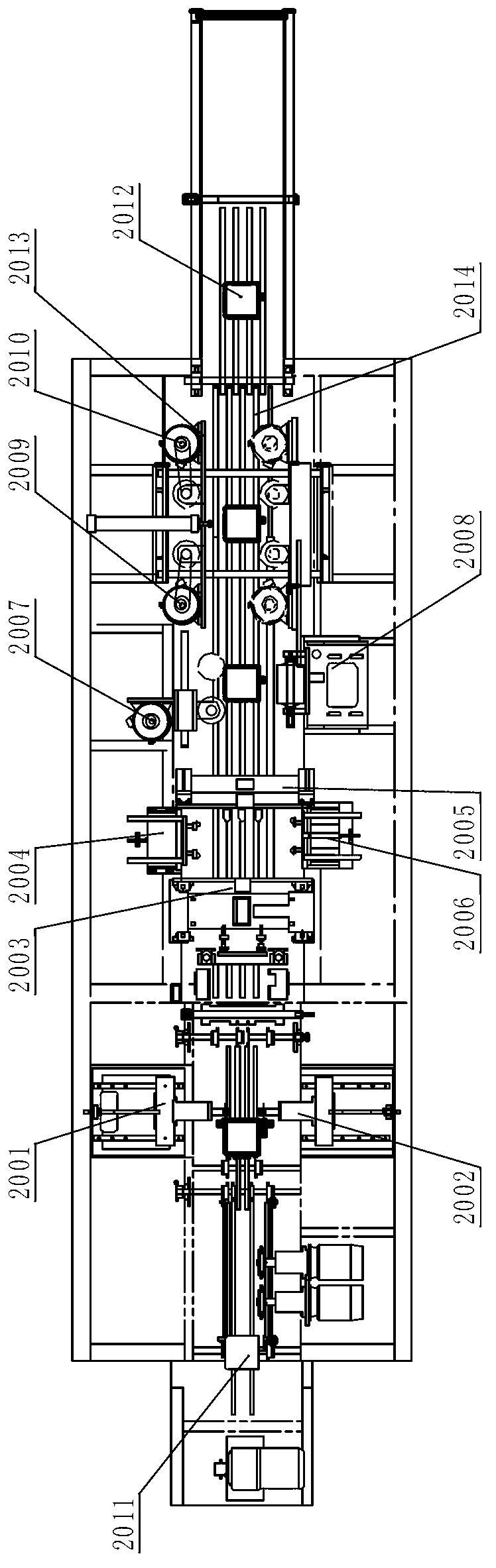

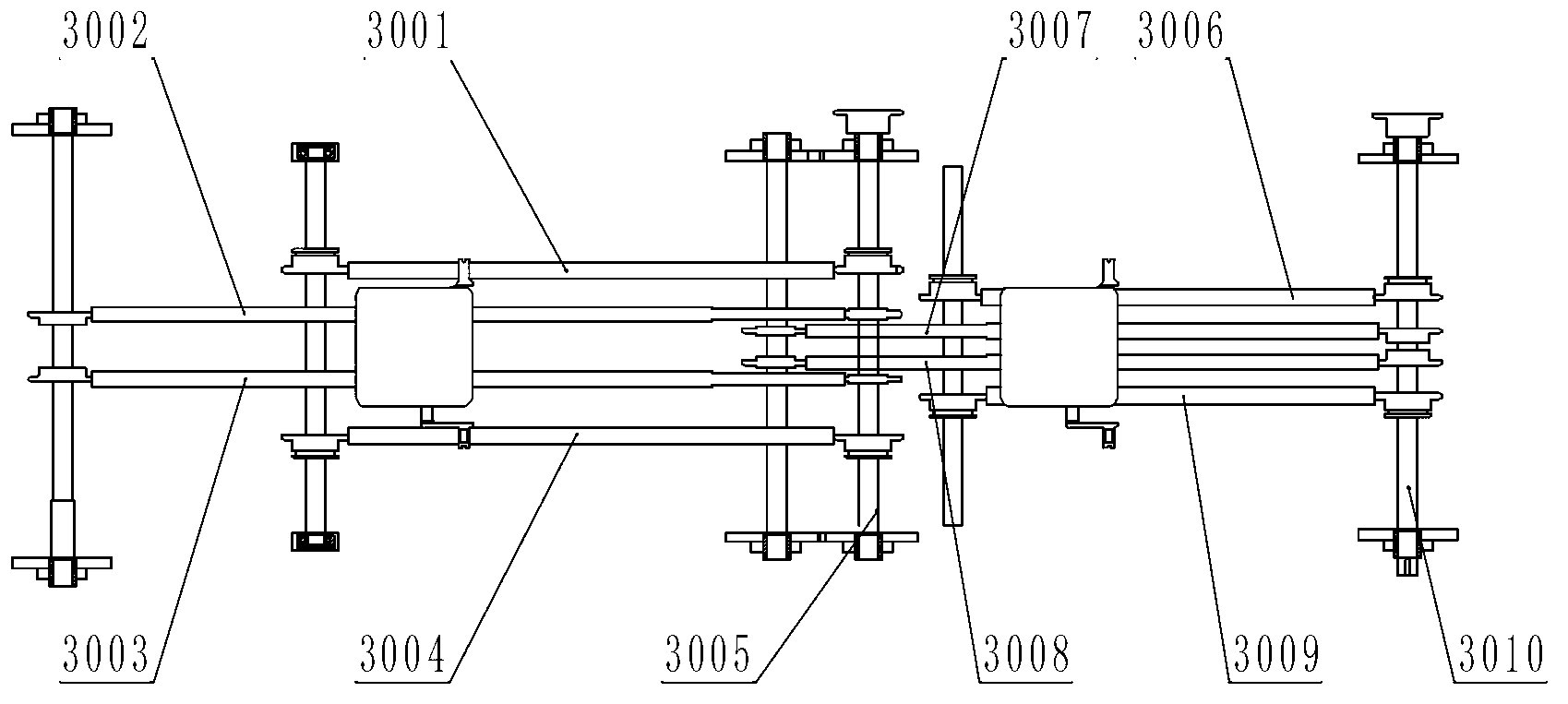

[0025] combine figure 1 , 2, 3, the plate conveying device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com