Packaging box for hoisting

A packaging box and hoisting technology, applied in the field of hoisting packaging boxes, can solve the problems of increasing the cost of transportation transition time and the limited quantity of single transportation, and achieve the effects of increasing strength, improving bonding strength, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

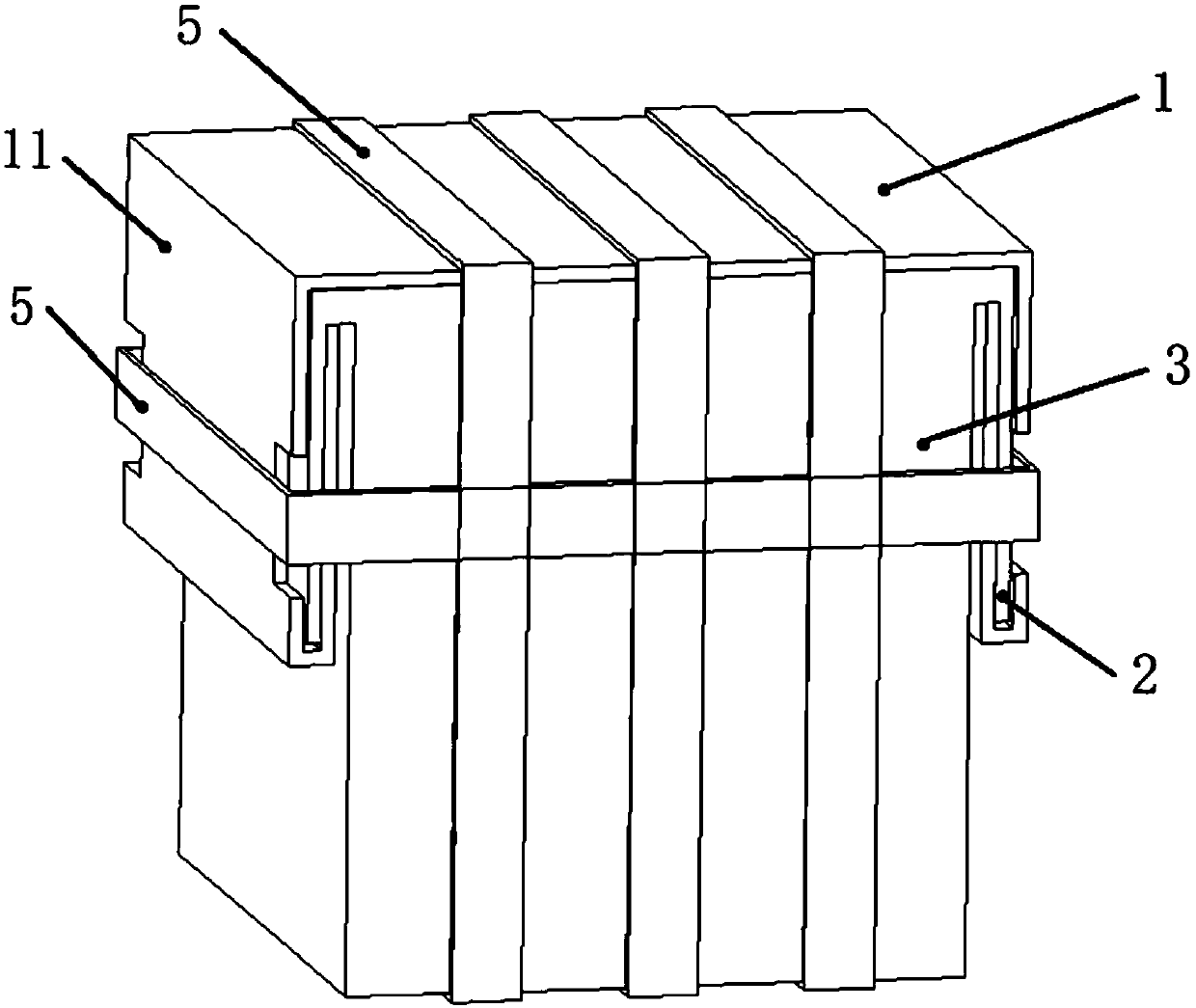

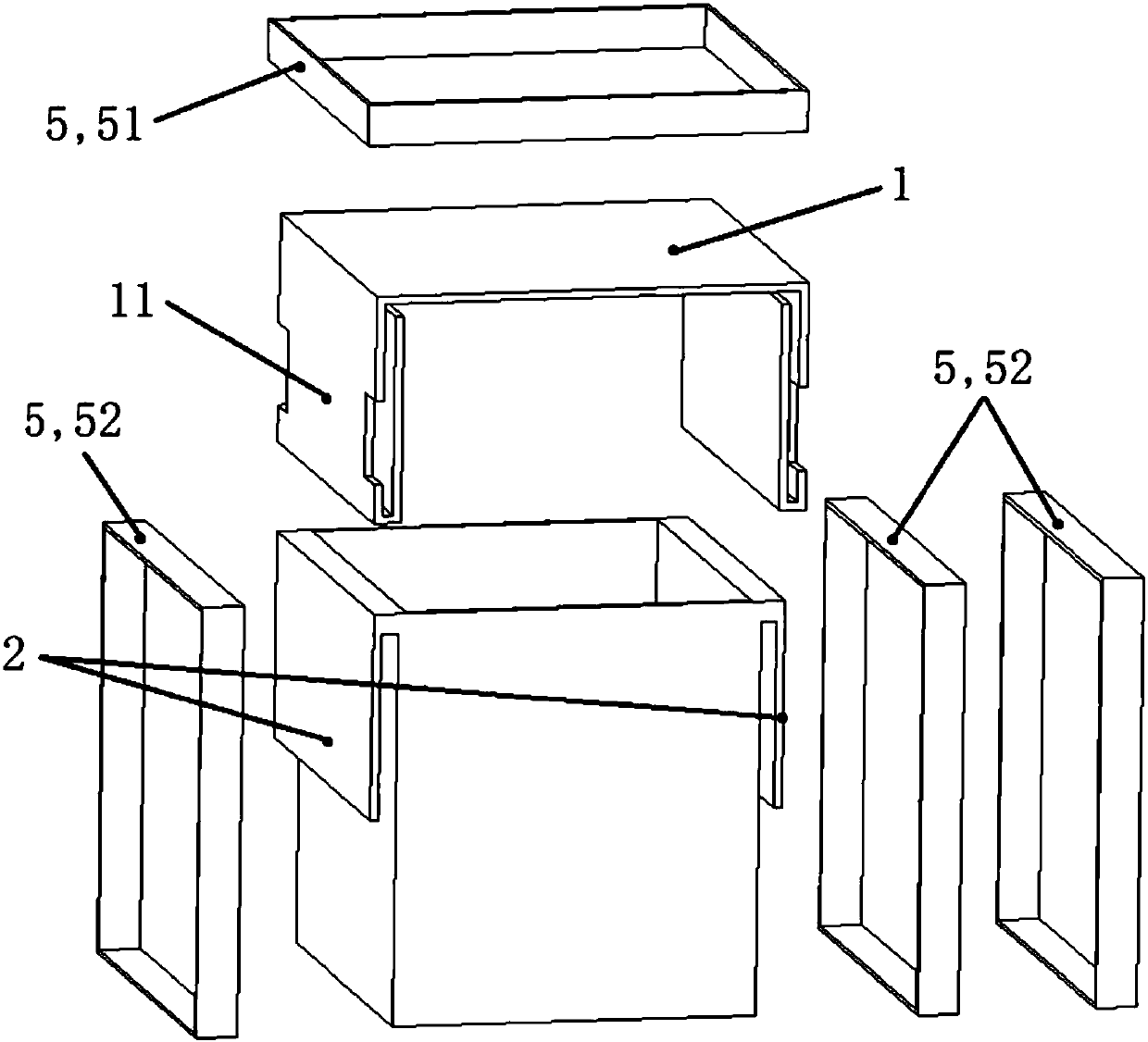

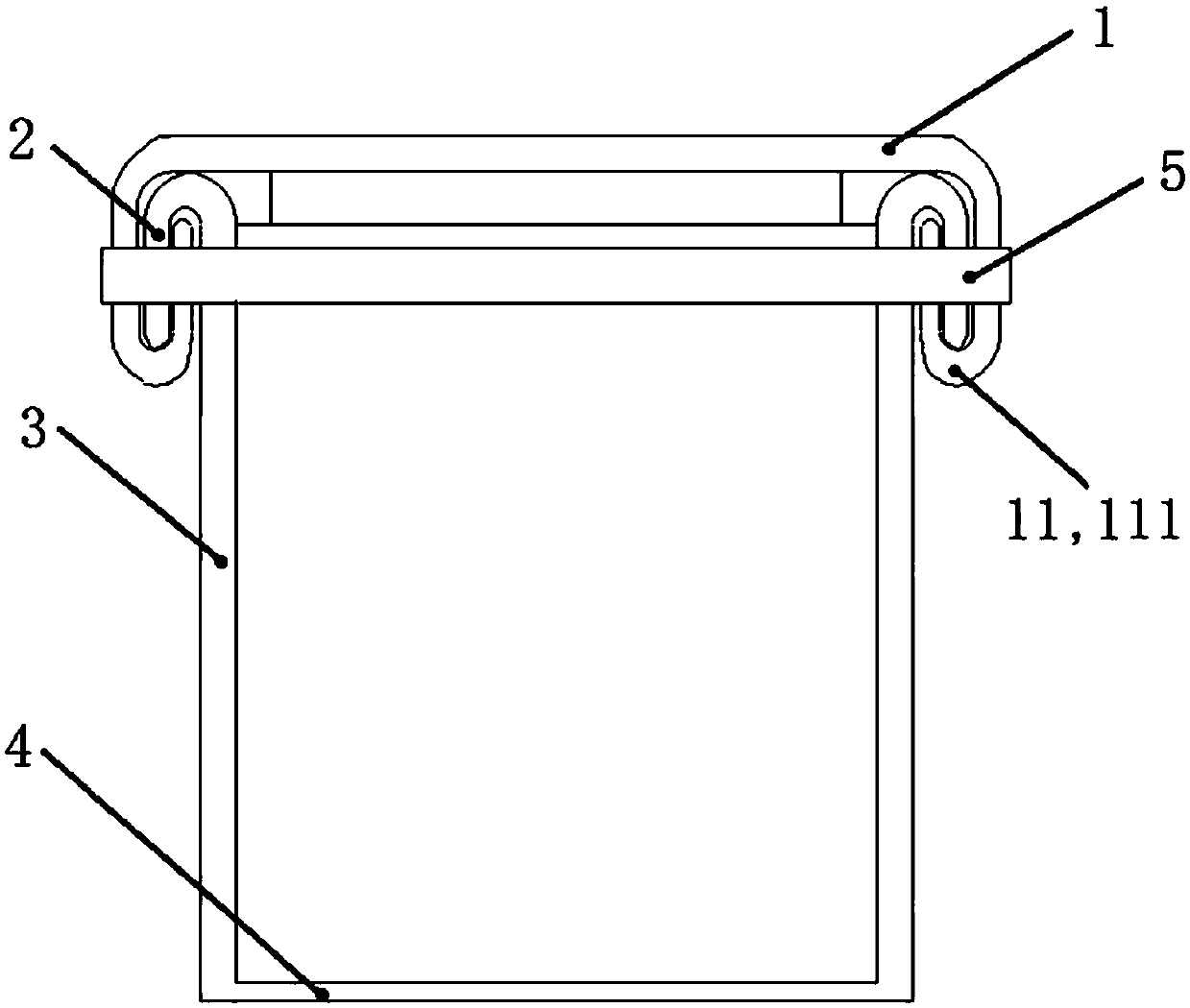

[0044] In this example, if figure 1 and figure 2 As shown, a packing box for hoisting includes a bottom plate 4, a side plate 3 and a shake cover 2 extending vertically upward along the side plate 3, and the packing box also includes a box cover 1 that can be separated from the box body, so The edge of the box cover 1 is provided with a number of folding lines 12 parallel to the upper edge of the side plate 3, and the user folds the box cover 1 along the folding lines 12 to obtain hanging ears 11 protruding to the outside of the box body. The folded rocking cover 2 is plugged in, so that the case cover 1 is located at the upper end of the case body.

[0045] In this example, if Figure 5 As shown, on the top box cover 1 that can be separated from the packing box, a bendable fold line 12 is set, and the box cover 1 is folded along the fold line 12 according to a certain direction sequence, so that the fold line part of the box cover 1 can form a protrusion or a depression T...

Embodiment 2

[0065] In this example, if figure 1 and figure 2 As shown, a packing box for hoisting includes a bottom plate 4, a side plate 3 and a shake cover 2 extending vertically upward along the side plate 3, and the packing box also includes a box cover 1 that can be separated from the box body, so The edge of the box cover 1 is provided with a number of folding lines 12 parallel to the upper edge of the side plate 3, and the user folds the box cover 1 along the folding lines 12 to obtain hanging ears 11 protruding to the outside of the box body. The folded rocking cover 2 is plugged in, so that the case cover 1 is located at the upper end of the case body.

[0066] In this example, if Figure 5 As shown, on the top box cover 1 that can be separated from the packing box, a bendable fold line 12 is set, and the box cover 1 is folded along the fold line 12 according to a certain direction sequence, so that the fold line part of the box cover 1 can form a protrusion or a depression T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com