Air inlet structure for turbojet engine nacelle

A technology of nacelle and turbojet, which is applied in the direction of the air intake of the turbine/propulsion device, the combustion of the air intake of the power plant, engine components, etc., and can solve the problem of sealing defects, large thickness of the air intake lip, and the inner surface of the air intake Aerodynamic performance degradation and other issues, to achieve the effect of improving mechanical strength and reducing axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

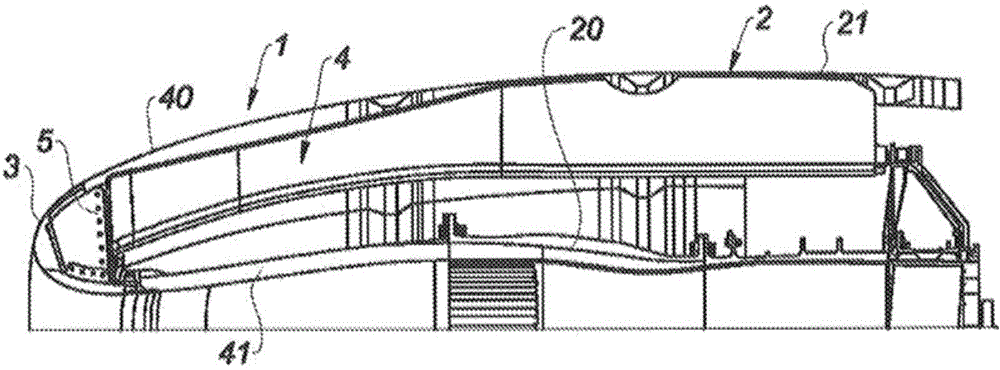

[0044] The nacelle usually has a generally tubular structure that includes an air intake ( figure 1 ), the middle section surrounding the turbojet fan, and the downstream section accommodating the thrust reverser device and surrounding the turbojet engine combustion chamber. The nacelle usually ends in a jet nozzle, and the outlet of the jet nozzle is located downstream of the turbojet engine.

[0045] figure 1 A longitudinal sectional view of the air intake structure 1 according to the prior art is shown.

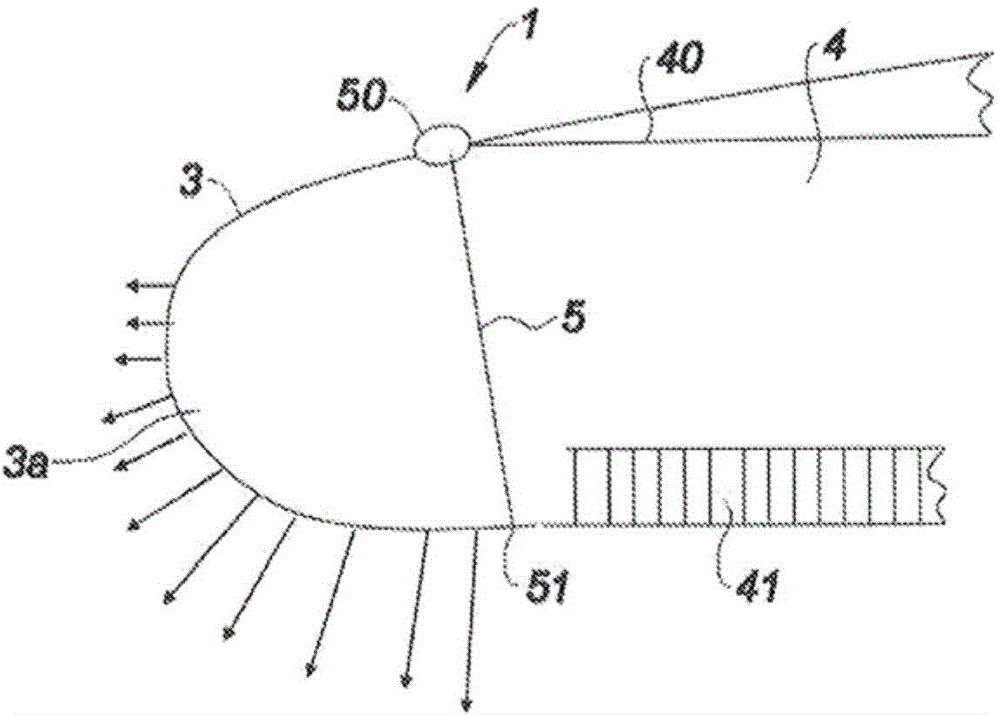

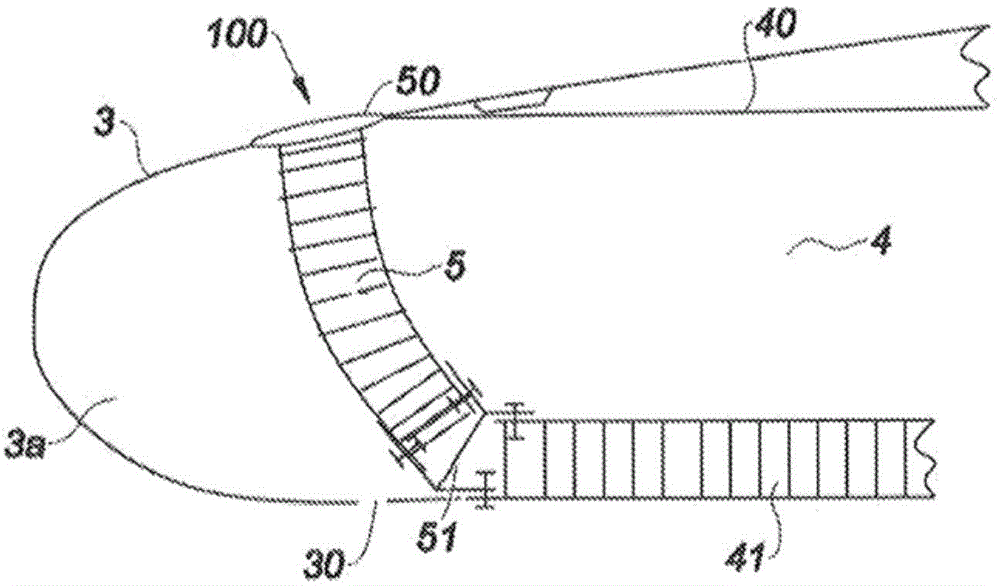

[0046] The air intake structure 1 is located upstream of the middle section 2 of the nacelle, and includes an air intake lip 3 on the one hand, suitable for allowing the air to be supplied to the turbine engine to be optimally captured towards the turbojet engine; on the other hand, it includes a downstream structure 4. The lip is attached to the downstream structure 4 and guides air appropriately to the fan blades.

[0047] More specifically, the air inlet structure 1 generally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com