7-series hard alloy row material extrusion mold

An extrusion die and hard alloy technology, which is applied in the field of 7-series hard alloy material row extrusion dies, can solve the problems of 4 corner slumps at the edge of the row, poor fluidity, and cracking of the row corner, etc., to improve production efficiency. and yield, reduce the probability of bridge bending, and reduce the effect of unqualified edge size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples.

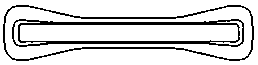

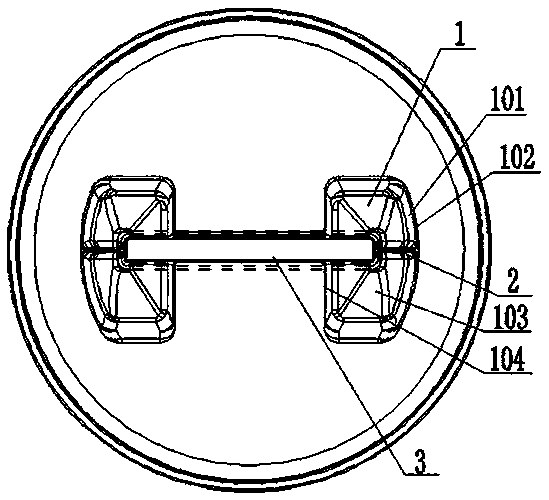

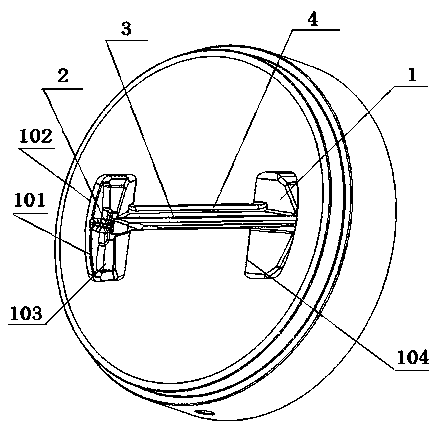

[0026] A 7-series hard alloy material discharge extrusion die, including a material inlet, the material inlet includes a middle feeding part 3 and a side feeding part 1; the side feeding part 1 is symmetrically arranged on both sides of the middle feeding part 3 form a butterfly, combine figure 2 and 3 As shown, the middle feeding part 3 is strip-shaped, and the side feeding parts 1 on both sides are in the shape of symmetrical butterfly wings. figure 1 The shown vertical center line is symmetrical, the outer edge line 102 of the side feeding part 1 is arc-shaped to match the shape of the extrusion barrel, and the area of the upper area separated by the central extension line of the middle feeding part 3 is smaller than the lower area Area, the separation described here is only a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com