Crankshaft large fillet under cutting groove rolling mechanism

A technology of large rounded corners and undercut grooves is applied in the field of rolling mechanism to prevent the rollers from falling off, offsetting deformation, and positioning accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

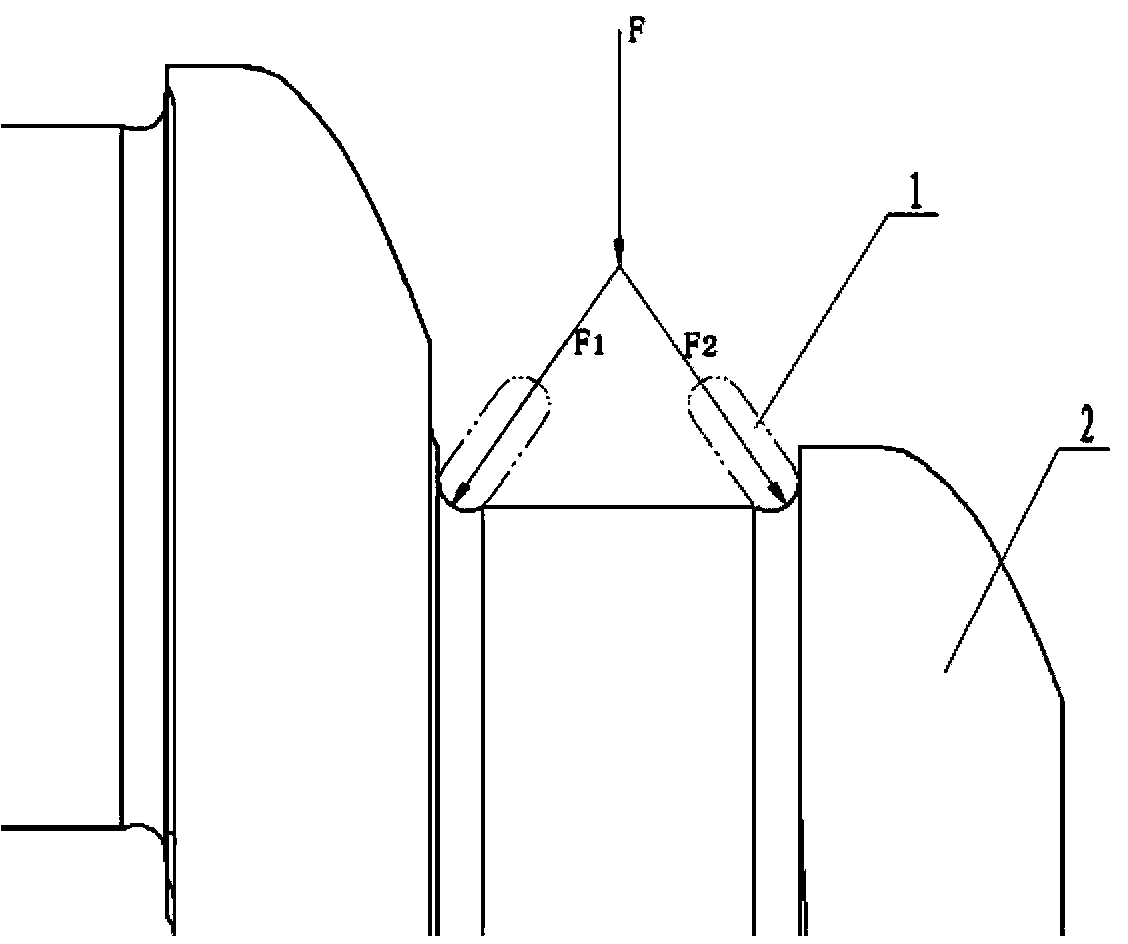

[0031] like figure 1 As shown, the roller 1 of the rolling mechanism of the present invention rolls on the fillet undercut groove of the crankshaft 2, and the force application mechanism applies a vertically downward force F, and the force F is decomposed into force F1 and force F2 along the roller direction (i.e. Rolling force), the roller 1 presses the crankshaft 2 fillet undercut groove inwardly by a certain amount, so as to realize the rolling of the crankshaft 2 fillet undercut groove.

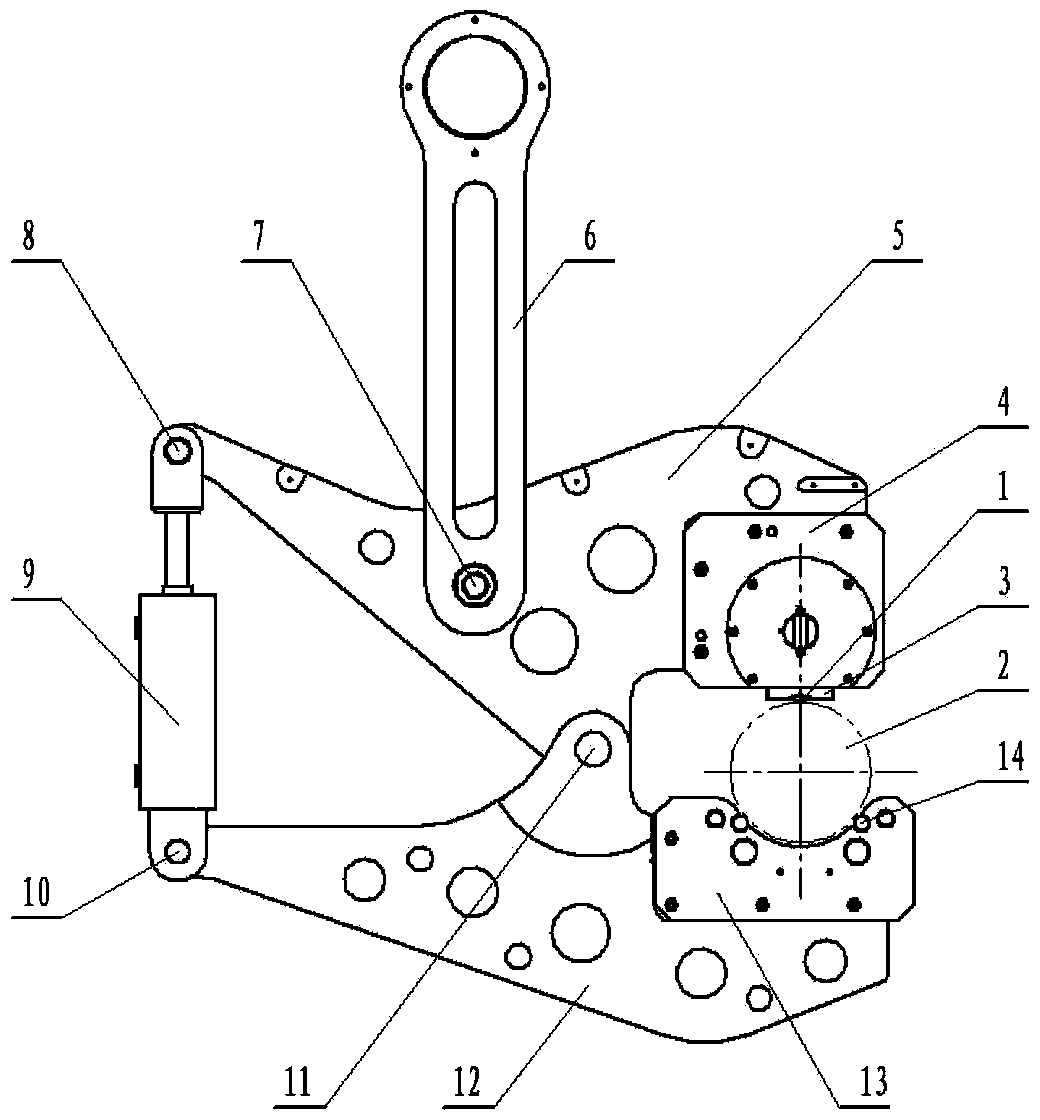

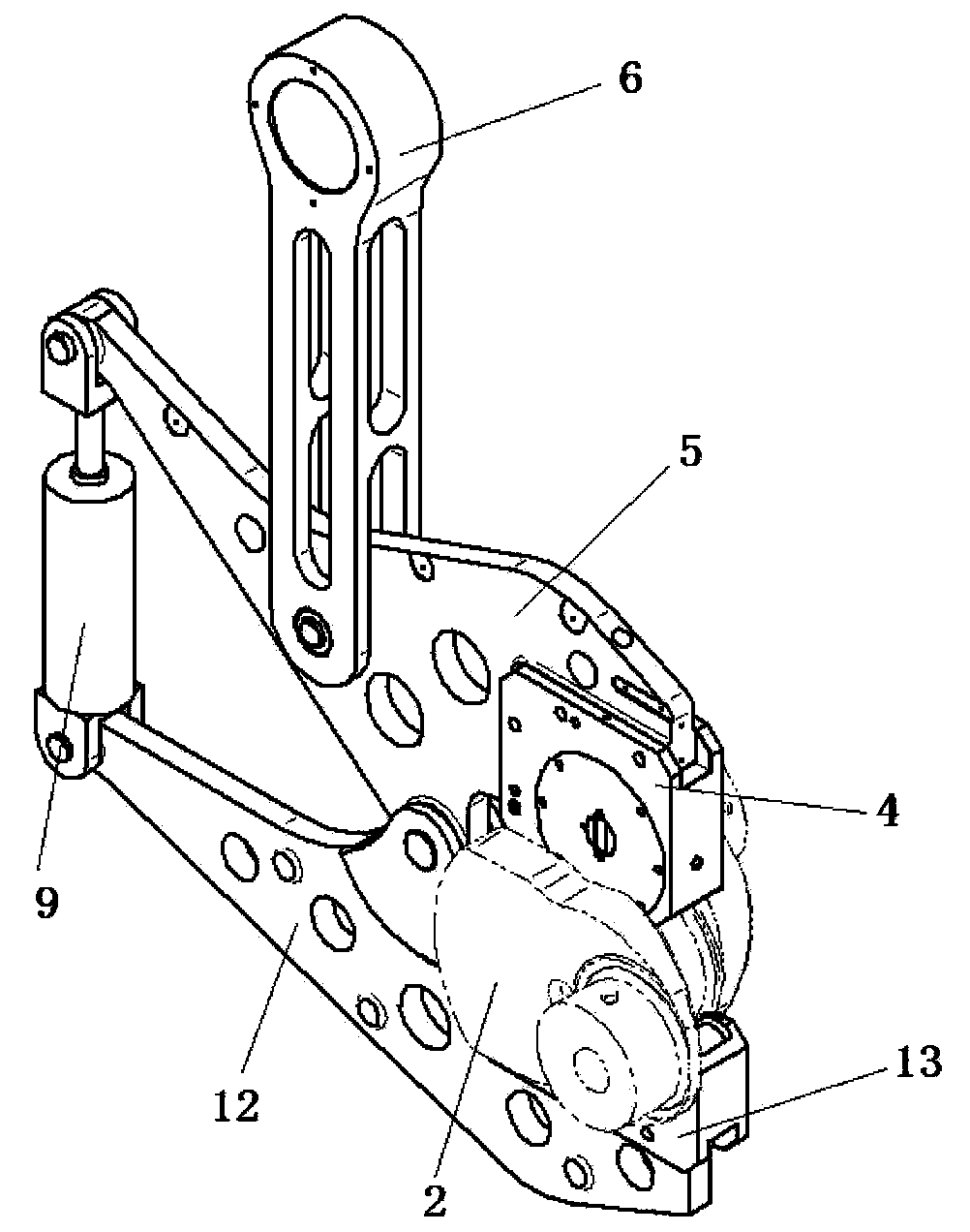

[0032] like figure 2 , 3 As shown, the integrated roller clamp 3 provides a limit for the roller 1 to prevent the roller 1 from falling, and at the same time leaves a certain gap so that the rounded corner of the roller 1 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com