Bending machine and operation method thereof

A bending machine and frame technology, applied in the field of bending machines, can solve the problems of time-consuming and laborious adjustment, increase the production cost, affect the rigidity of the machine, etc., and achieve the effect of simple operation method, easy implementation and simplified overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

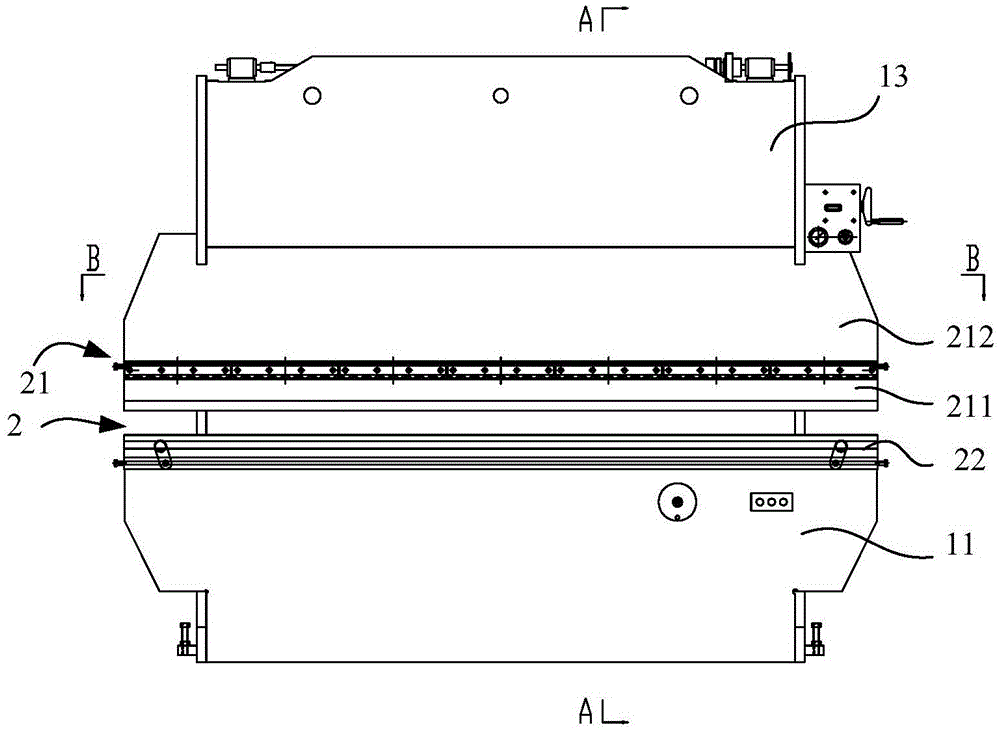

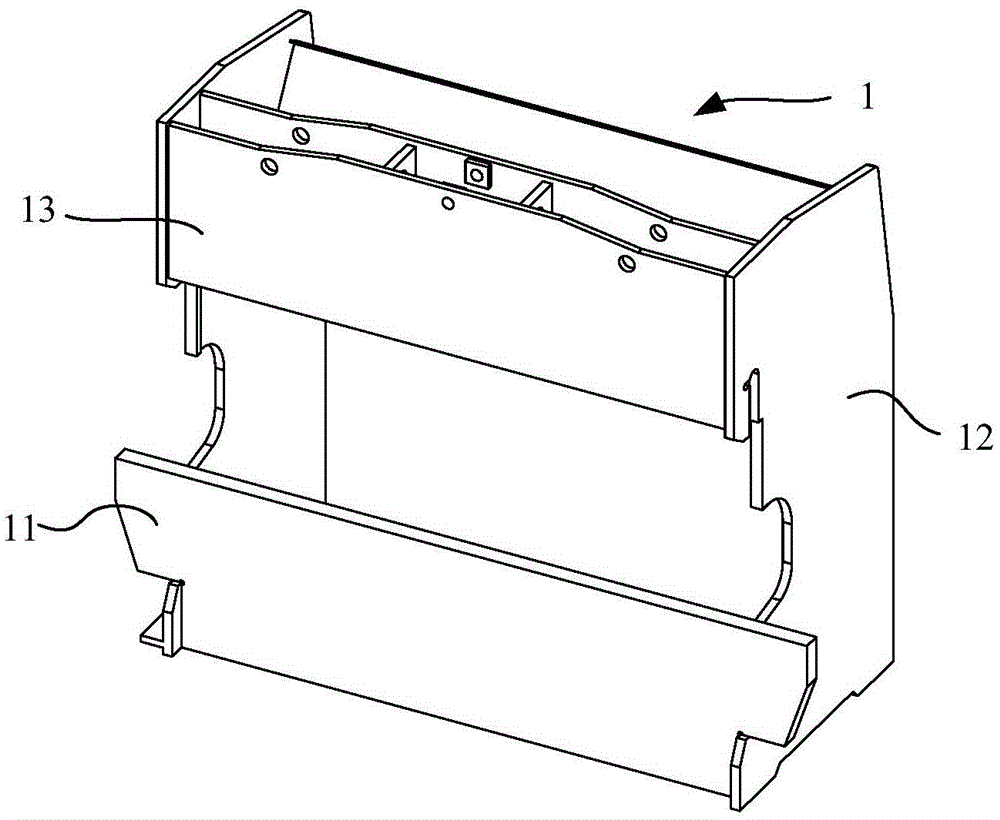

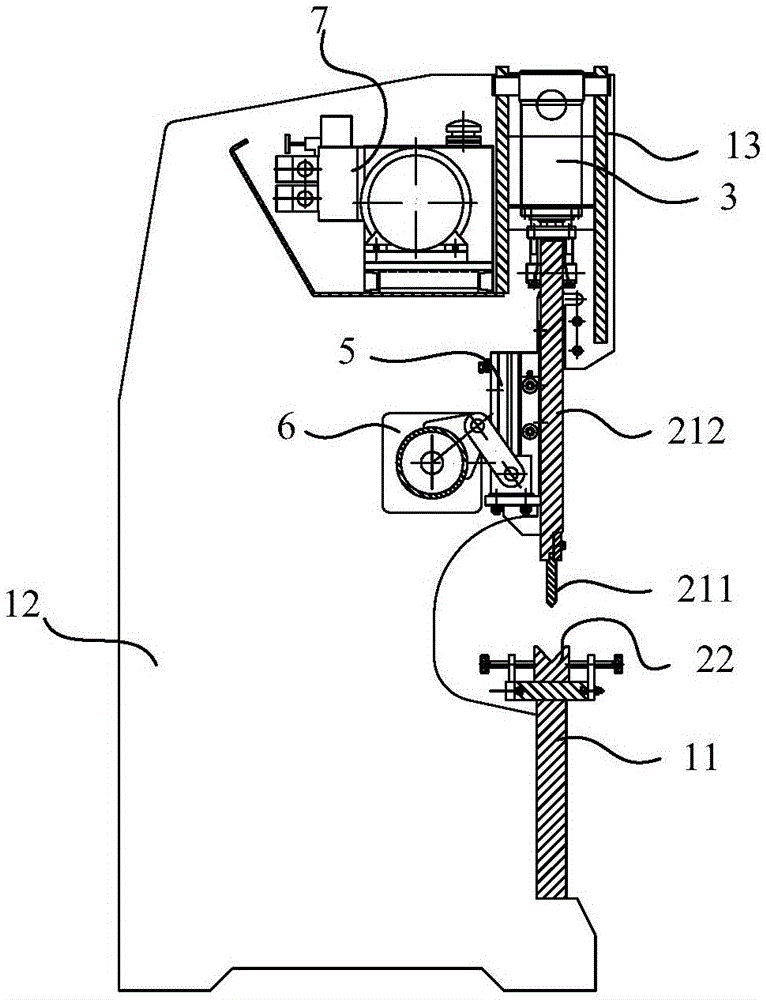

[0040] Such as figure 1 As shown, a bending machine includes a frame 1 and a mold 2 arranged on the frame 1, such as figure 2 As shown, the frame 1 includes a workbench 11, side panels 12 and top beams 13, as image 3 As shown, the mold 2 includes an upper mold 21 and a lower mold 22 that cooperate with each other, the lower mold 22 is fixed on the workbench 11, and three oil cylinders 3 are arranged above the upper mold 21, as Figure 4 As shown, three oil cylinders 3 are fixed on the top crossbeam 13, and the upper mold body 21 includes an upper mold body 211 and a slider 212, and the upper mold body 211 is detachably fixed on the lower end of the slider 212, so that it is convenient to replace and maintain the upper mold body 211 separately The three oil cylinders 3 are arranged above the slide block 212, the piston rods 31 of the three oil cylinders 3 are all connected with the slide block 212, and the force on the slide block 212 is even, so that the bending straightnes...

Embodiment 2

[0048] The bending machine of this embodiment has the same basic structure as that of Embodiment 1, including a frame 1 and a mold 2 arranged on the frame 1. The mold 2 includes an upper mold 21 and a lower mold 22 that cooperate with each other. Three oil cylinders 3 are provided, and the three oil cylinders 3 apply the same force to the upper die 21 .

[0049] The difference from Embodiment 1 is that the specific structure of the frame 1 is not limited, the specific structure of the upper mold 21 and the lower mold 22 is not limited, as long as the bending can be realized, and the number of the oil cylinders 3 is not limited, it can be the upper mold 21 provides power and can realize deflection compensation to the workpiece.

Embodiment 3

[0051] The operation method of the bending machine is as follows: first, bend the workpiece through the mold 2; secondly, perform deflection compensation on the workpiece: when the upper die 21 goes down to the bottom dead center to complete the bending of the workpiece, continue to control the oil cylinder 3 The output force can make the middle part of the upper mold 21 convex and deformed, and the deformation in the middle of the upper mold 21 just offsets the deformation of the lower mold 22 and the worktable 11 supporting the lower mold 22 under the force, as Figure 9 and 10 shown. The factors affecting the deformation of the upper mold 21 are the stiffness of the frame 1 and the output force of the cylinder 3, and the output force of the cylinder 3 changes with the bending force of the workpiece, so the material of the workpiece determines the output of the cylinder 3. The output force of the oil cylinder 3 determines the deformation of the upper die 21; therefore, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com